Smelting method of HIC (Hydrogen Induced Crack)/SSCC (Sulfide Stress Corrosion Cracking)-preventing steel

A smelting method and converter smelting technology, which is applied in the field of out-of-furnace refining and smelting and converter, can solve problems not involving HIC/SSCC steel, and achieve the effect of transformation and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

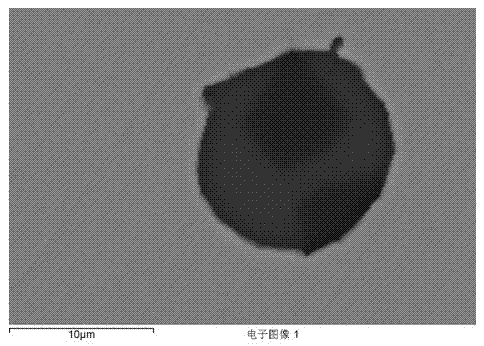

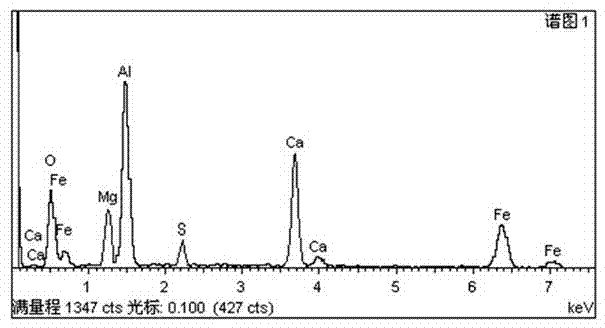

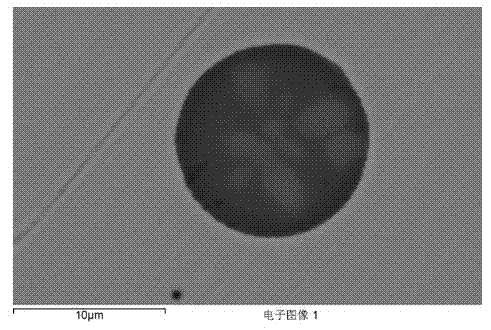

Image

Examples

Embodiment 1

[0017] The molten iron is pretreated before entering the furnace. After the treatment, the composition of the molten iron is: S=0.012%, P=0.15%, Si=0.43%, and the temperature is 1295°C. The slag is cleaned before the molten iron enters the converter. Converter smelting adds molten iron and scrap steel, 135 tons of molten iron and 18 tons of scrap steel. Converter smelting adopts double slag method, converter end point control C=0.080%, P=0.010%, temperature 1630°C; strict slag blocking, tapping time 5min, adding aluminum deoxidizer to the ladle when tapping 1 / 5 Carry out deoxidation, add 900kg of synthetic slag to the ladle at the same time, add the alloy and slag when 2 / 5 of the steel is tapped, and add other alloys according to normal requirements; after the converter furnace, carry out strong argon blowing and stirring on the molten steel, the content of acid-soluble aluminum in the steel It is 0.063%, the temperature is 1572 ℃, feed 100 m aluminum wire.

[0018] After the...

Embodiment 2

[0022] The molten iron is pretreated before entering the furnace. After treatment, the composition of the molten iron is: S=0.013%, P=0.15%, Si=0.46%, and the temperature is 1291°C. The slag must be cleaned before the molten iron enters the converter. Converter smelting adds molten iron and scrap steel, 133 tons of molten iron and 15 tons of scrap steel. Converter smelting adopts double slag method operation, converter end point control C=0.060%, P=0.008%, temperature 1627°C; strict slag blocking, tapping time 5min, adding aluminum deoxidizer to ladle for 1 / 5 of tapping Deoxidation, while adding 900kg of synthetic slag to the ladle, the alloy and slag are added when 2 / 5 of the steel is tapped, and other alloys are added according to normal requirements; 0.069%, the temperature is 1570 ℃, feed 80 m aluminum wire.

[0023] After the molten steel is transported to the LF refining station, the argon blowing pipe is connected to blow argon at the bottom of the molten steel, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com