Bismuth-sodium titanate-bismuth potassium titanate barium zirconate titanate lead free piezoelectric ceramics

A technology of bismuth potassium titanate and barium zirconate titanate, which is applied in the field of bismuth sodium titanate-bismuth potassium titanate-barium zirconate titanate lead-free piezoelectric ceramics, can solve the problem of lead-free piezoelectric ceramics preparation and performance that have not been reported and other problems, to achieve the effect of excellent piezoelectric ferroelectric performance, excellent piezoelectric ferroelectric performance, and process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

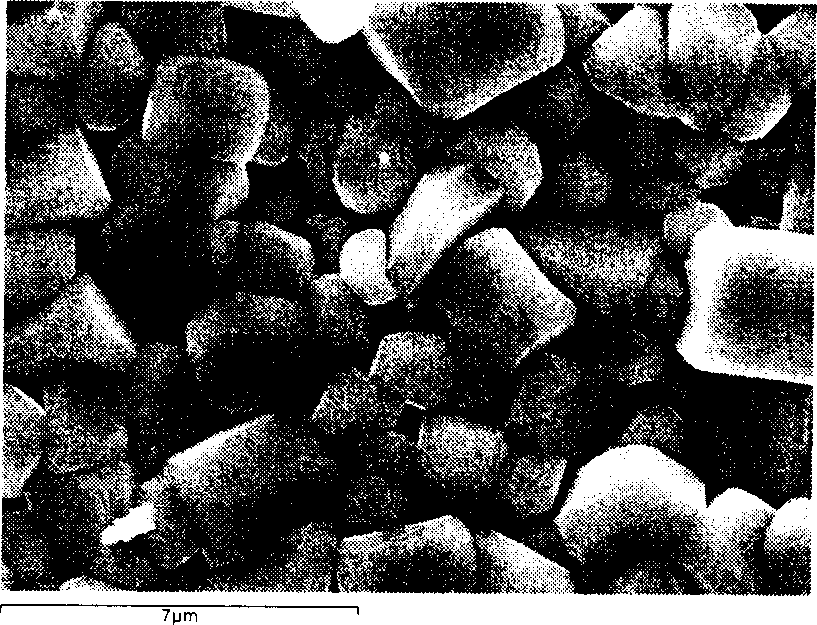

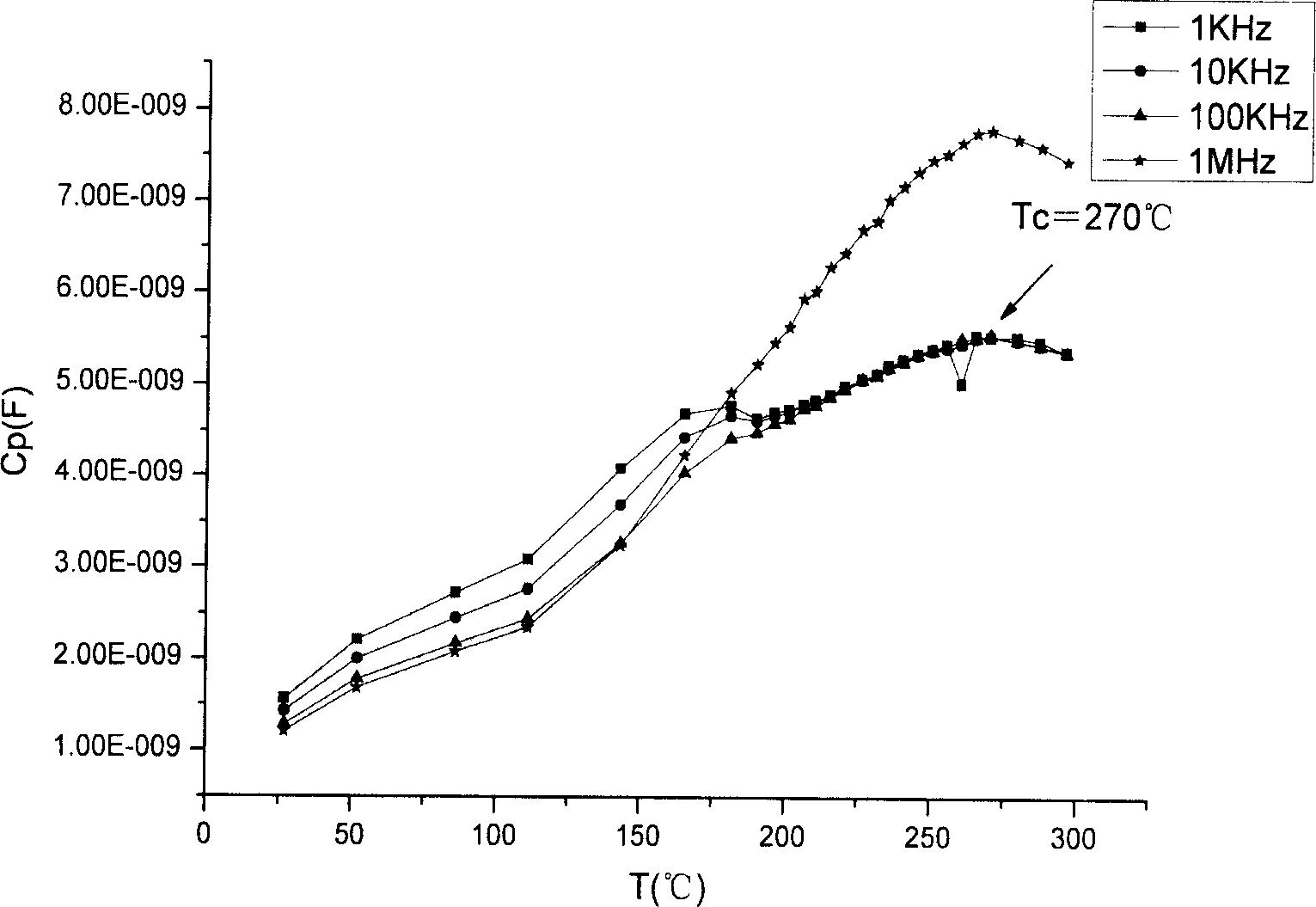

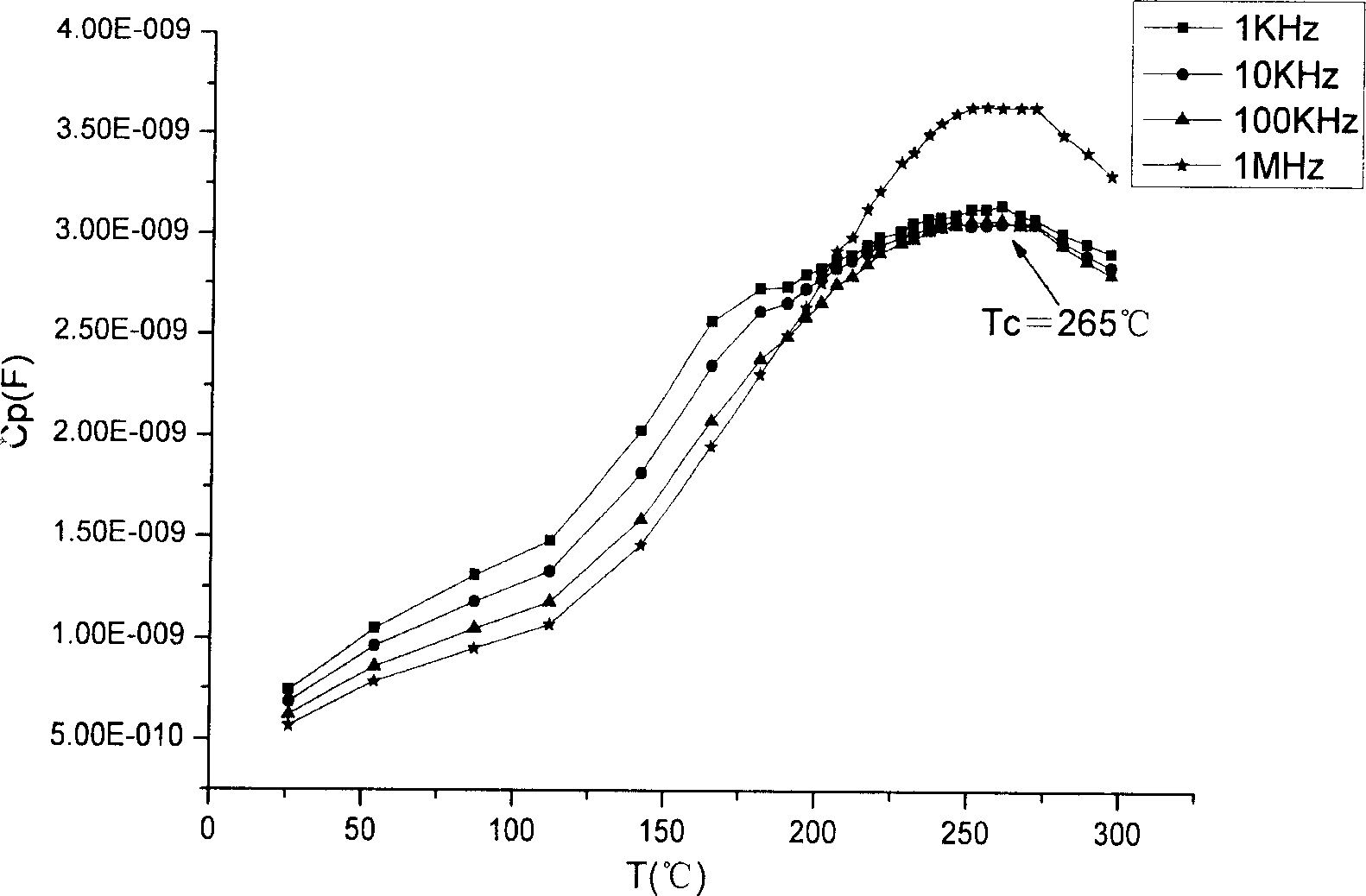

[0014] According to 0.9((1-z)Bi 1 / 2 Na 1 / 2 TiO 3 -zBi 1 / 2 K 1 / 2 TiO 3 )-0.1Ba(Zr y Ti1-y )O 3 The theoretical content of the ratio, referring to the MPB position of BNT-BKT, using Na 2 CO 3 、 Bi 2 o 3 、BaCO 3 、K 2 CO 3 、TiO 2 and ZrO 2 Analytical pure powder raw materials, according to the composition shown in Table 1, specifically according to the weight of each group shown in Table 3, after accurate weighing, the groups are ball milled with anhydrous ethanol as the ball milling medium, dried at 70°C, and pressed into discs, at 800-950°C Synthesize at ℃ temperature for 2 hours, sieve 200 meshes, add 0.5-1.5ml of 3wt% PVA solution per 10g of mixture as binder, press under 150MPa pressure to form 10mm in diameter and 1-1.5mm in thickness Discs were incubated at 1150°C for 3h. The fired samples were polished and covered with silver electrodes. The fired samples were polarized at 4kV / mm in silicone oil at 80°C. After 20 minutes of polarization, the electric field ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com