Barium zirconate titanate ceramic material with low dielectric loss and preparation method thereof

A technology of barium zirconate titanate and ceramic materials, which is applied in the field of barium zirconate titanate ceramic materials and its preparation, and can solve problems such as unreachable, large dielectric loss, and failure to meet application requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) BaCO 3 , CaCO 3 、TiO 2 , ZrO 2 According to the stoichiometric formula Ba 0.9 Ca 0.1 Ti 0.8 Zr 0.2 o 3 For batching, the ratio is: 15.4523g BaCO 3 , 0.8665g CaCO 3 , 5.5611gTiO 2 , 2.1443gZrO 2 , put about 20g of mixed powder into a nylon ball mill jar, add 200ml of deionized water, add 150g of zirconium balls, and mill on a planetary ball mill for 6 hours at a speed of 400 rpm;

[0021] (2) Place the ball-milled raw material in a drying oven, dry at 100°C, and then pass through a 40-mesh sieve;

[0022] (3) Put the sieved powder into a medium-temperature furnace, pre-fire at 1100°C, and keep it warm for 4 hours;

[0023] (4) Add 0.6wt.% Li to the pre-fired powder in step 3 2 CO 3 Mix, put into a ball mill jar, add zirconia balls and deionized water, ball mill for 12 hours, dry and sieve, then use a powder tablet press to press into a green body with a pressure of 4 MPa;

[0024] (5) The green body is sintered at 1350° C. and kept for 4 hours to prepa...

Embodiment 2-6

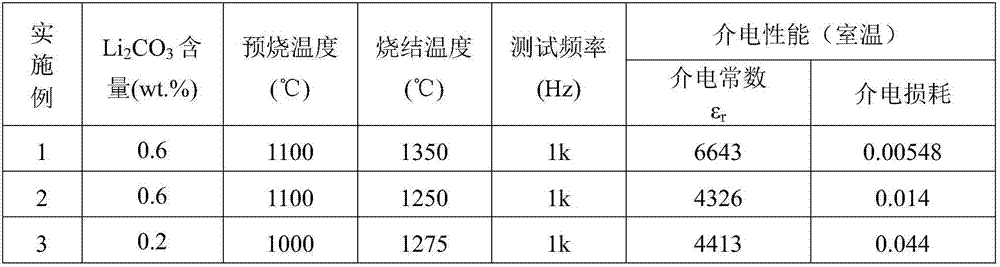

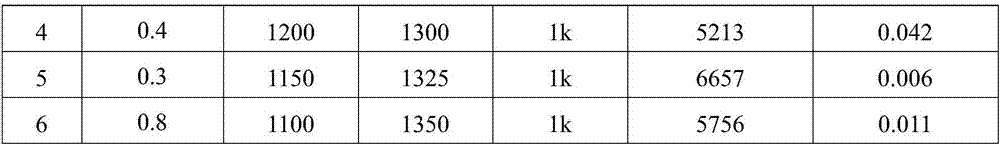

[0029] The sintering temperature and dielectric properties of the specific example are shown in Table 1, and the rest of the preparation process is exactly the same as that of Example 1.

[0030] Table 1

[0031]

[0032]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| sintering temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com