Patents

Literature

38results about How to "Moderate sintering temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

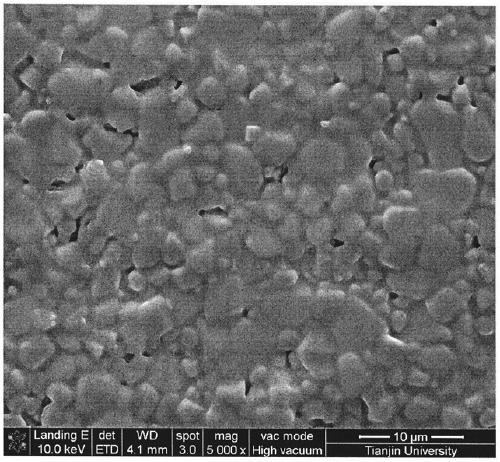

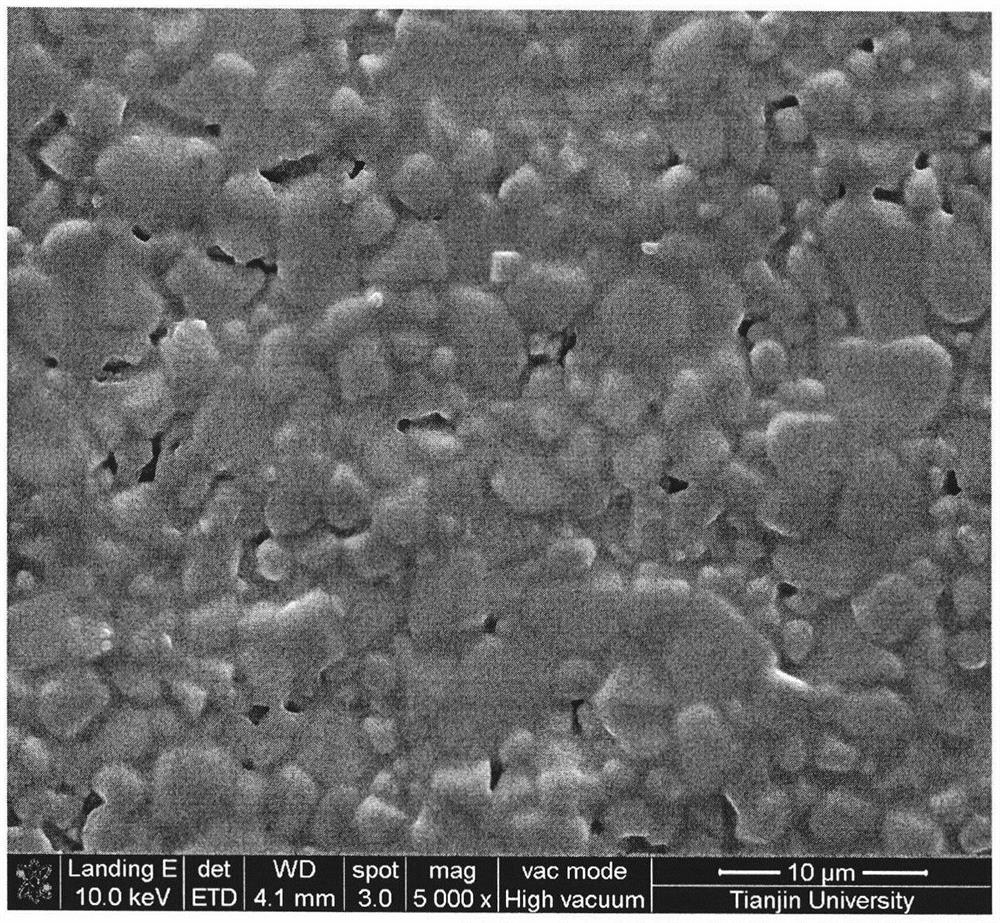

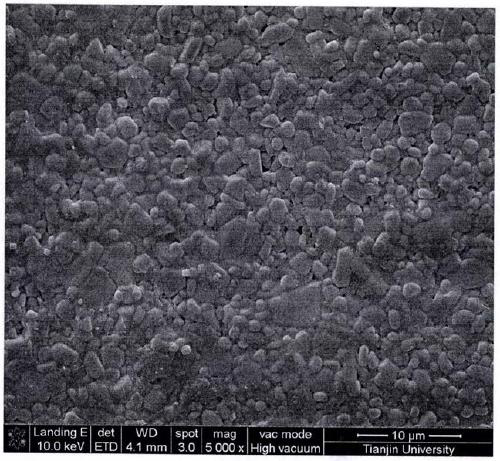

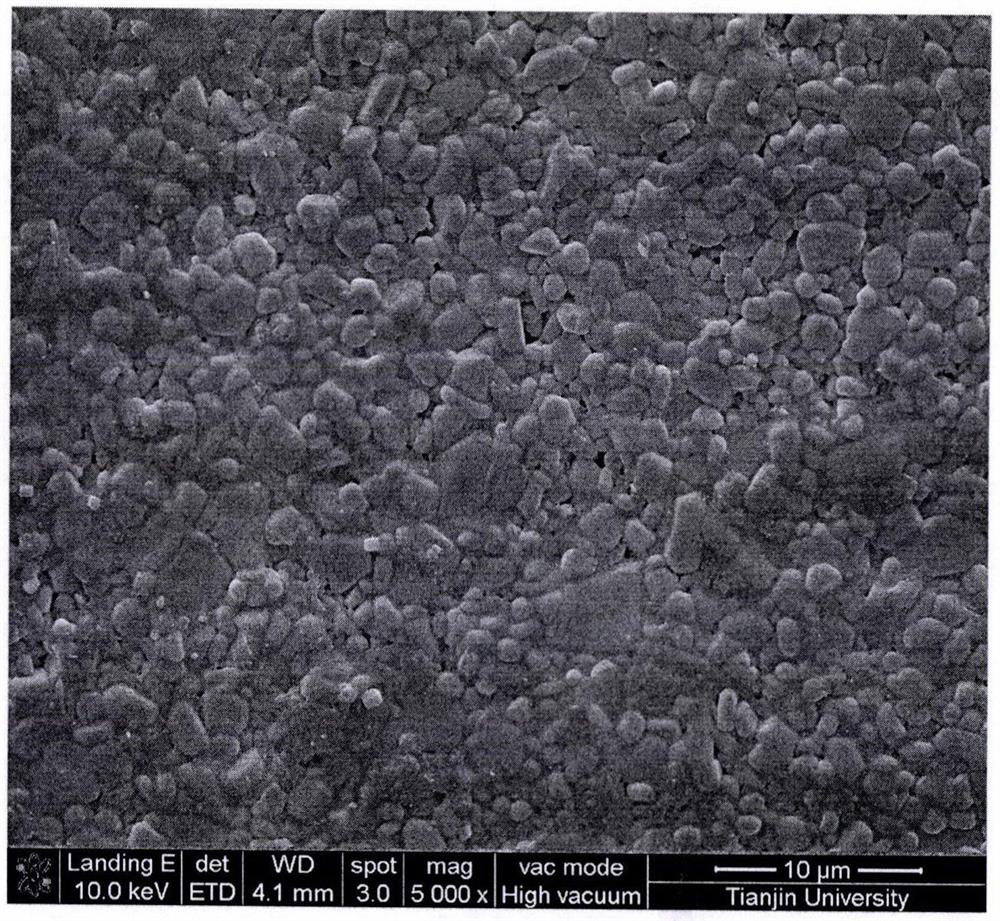

Low-temperature co-fired ceramic medium material and preparation method thereof

InactiveCN101823877AModerate sintering temperatureImprove performanceMetallic electrodeDielectric loss

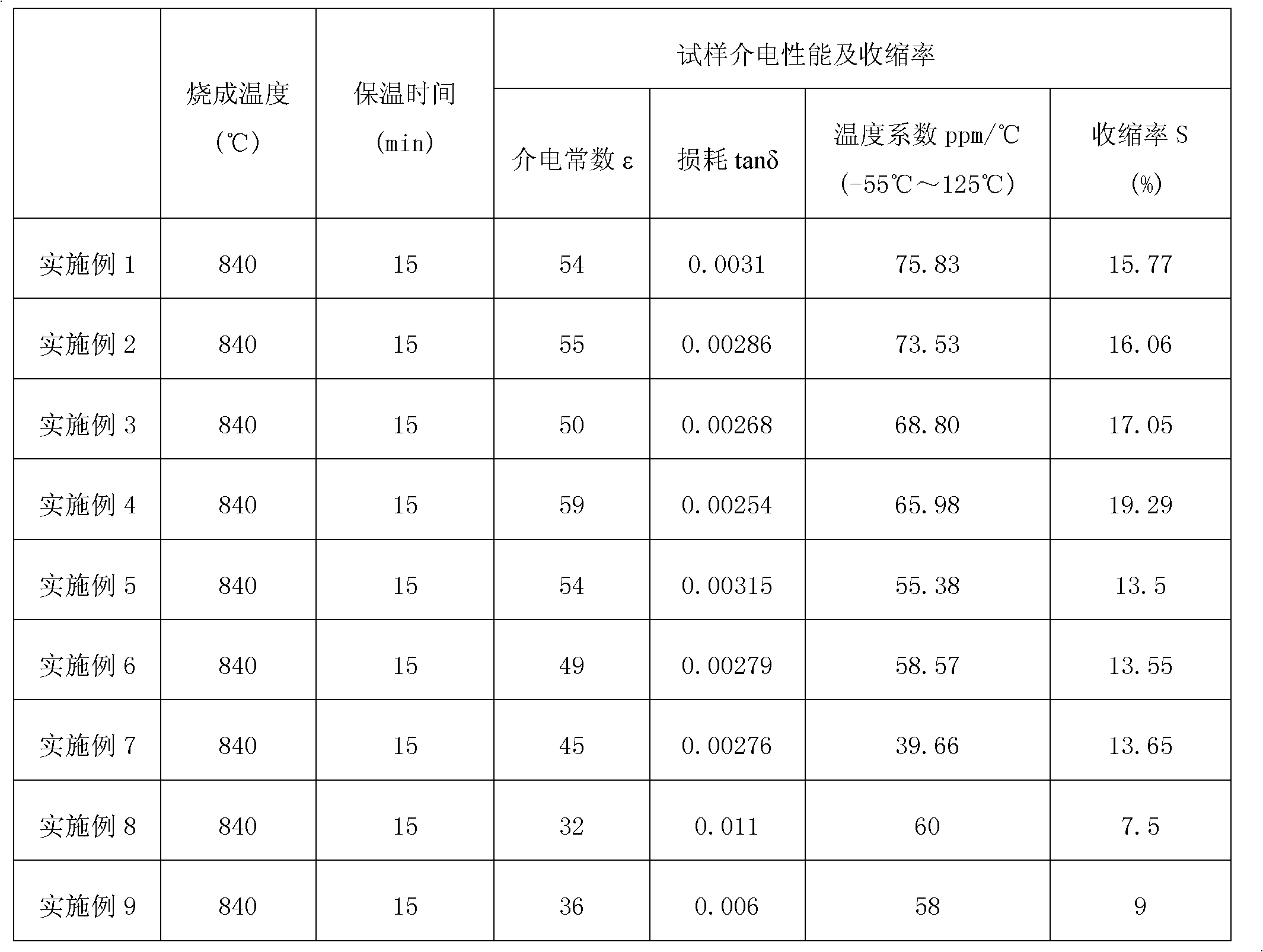

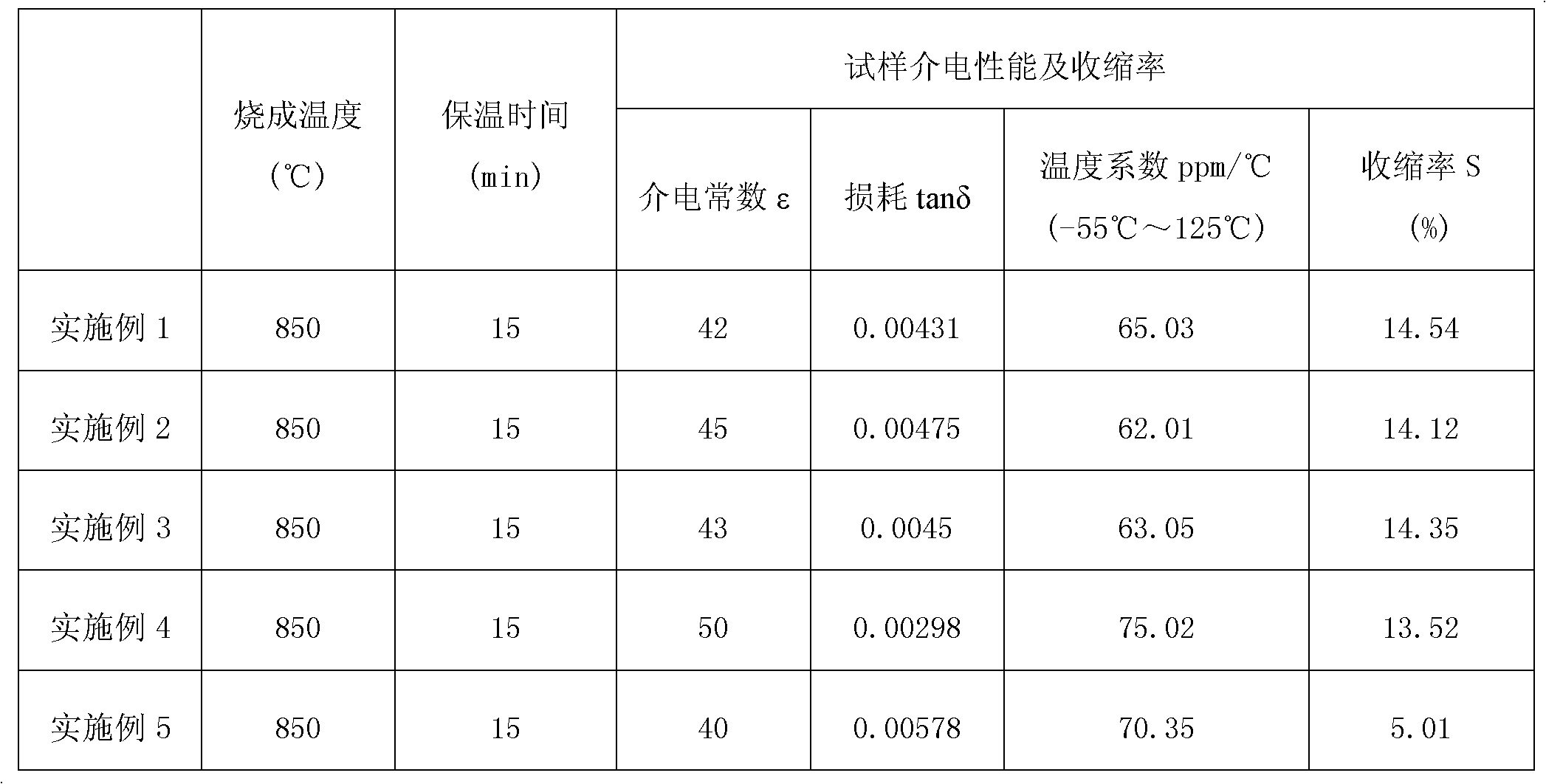

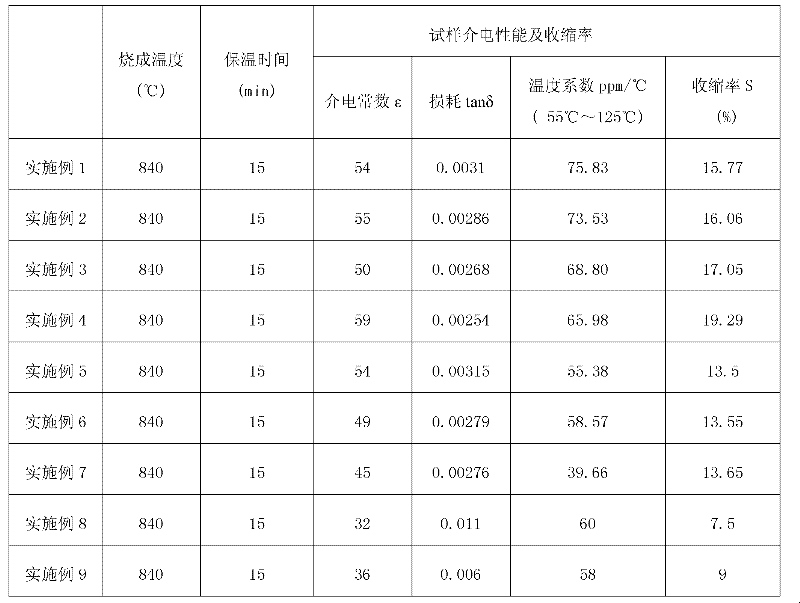

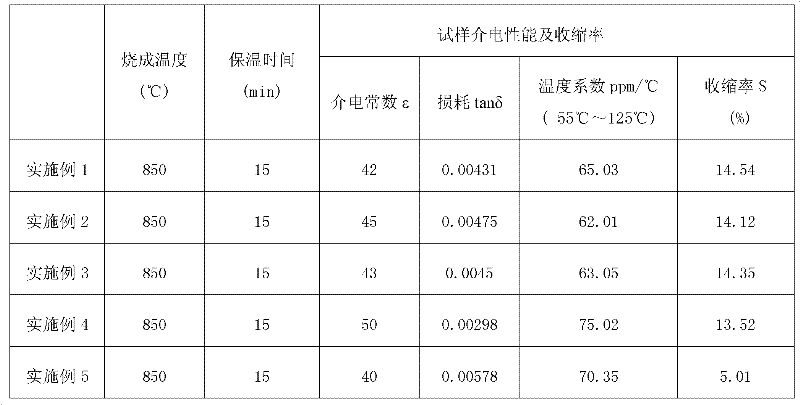

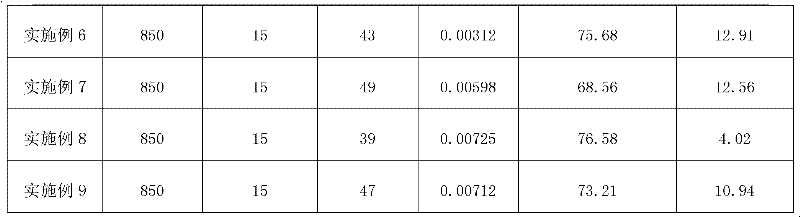

The invention discloses a low-temperature co-fired ceramic medium material. The material consists of 1 to 16 weight percent of glass powder and 84 to 99 weight percent of Ba6-3x(Nd0.4Bi0.6)8+2xTi18O54, wherein the x is 0.5 to 1.5. The glass powder is at least one of the following two types of glass powder, namely glass powder B consisting of 30 to 50 mass percent of Li2CO3 and 5 to 20 mass percent of SiO2 and 40 to 60 mass percent of H3BO3 and glass powder C consisting of 15 to 40 mass percent of LiF and 60 to 85 mass percent of BaF2. In a preparation process, first, clinker is prepared; then, secondary preparation of the glass powder and the clinker is performed; and finally, sintering is performed. A BaO-Nd2O3-Bi2O3-TiO2 system is selected and a method of adding the glass powder as a sintering aid is adopted, so the material has the characteristics of sintering temperature below 900 DEG C, high dielectric constant and low dielectric loss, simultaneously has a wide sintering shrinkage range, and can be co-fired with a silver metallic electrode with high conductivity.

Owner:TIANJIN UNIV

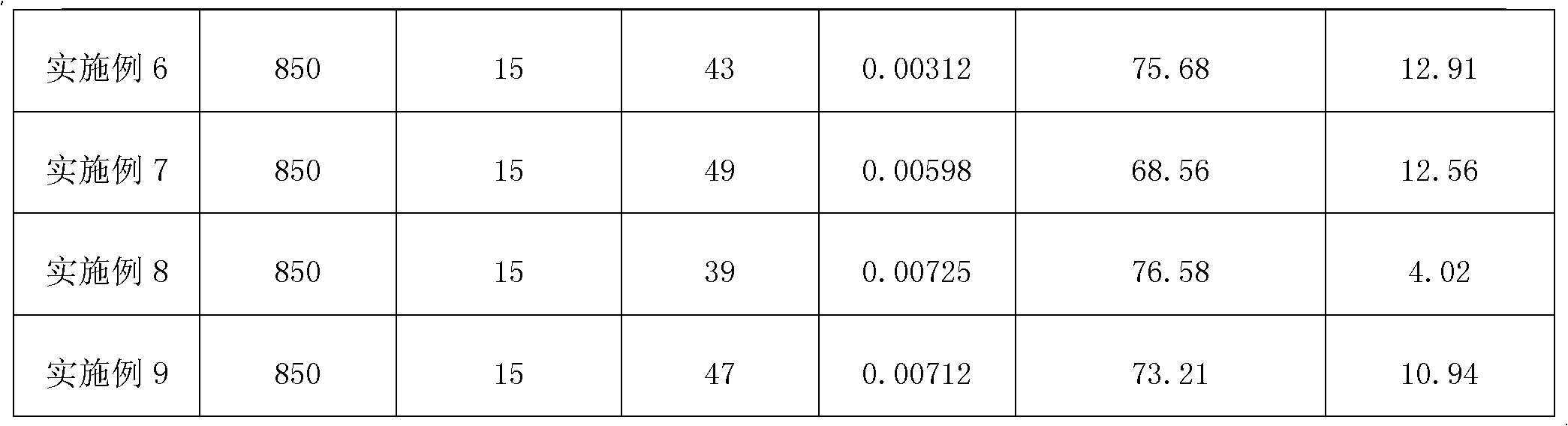

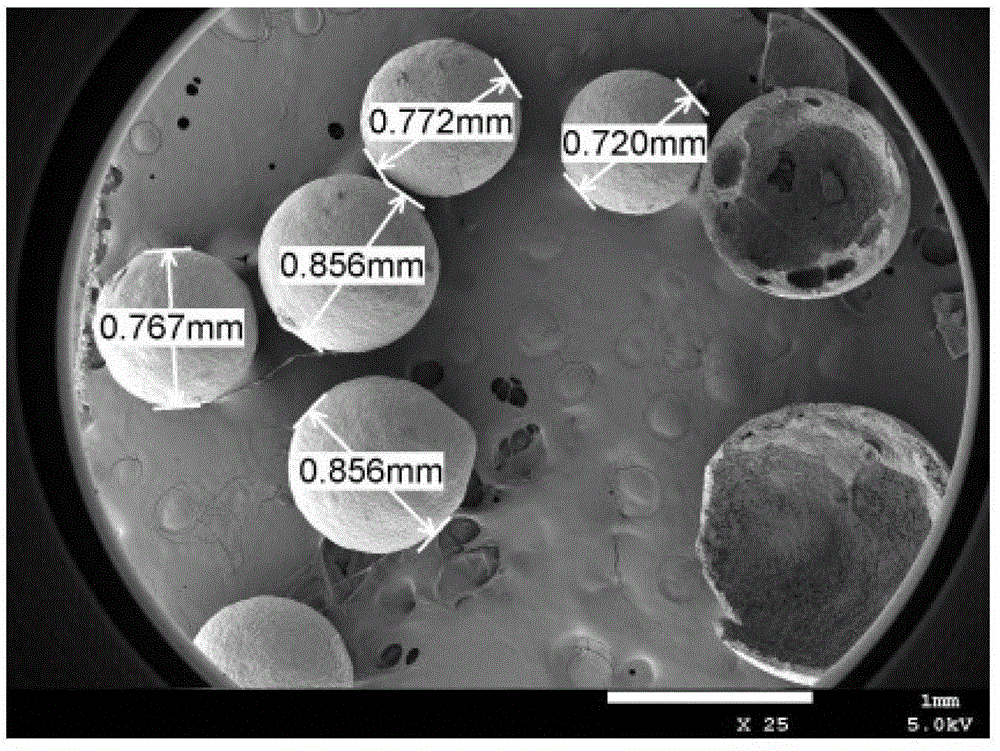

SiO2-Al2O3 hollow ceramic ball and preparation method thereof

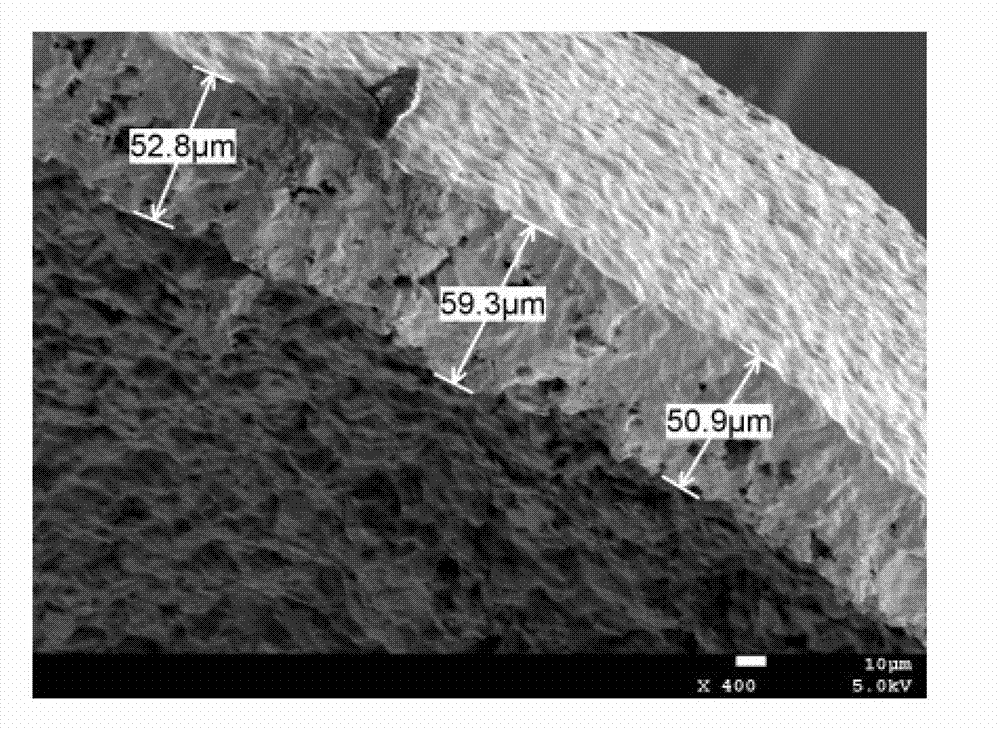

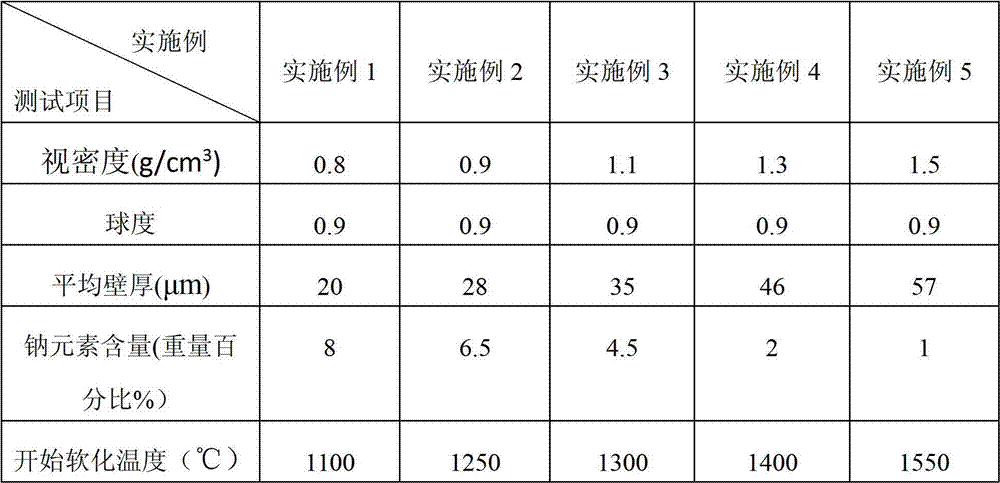

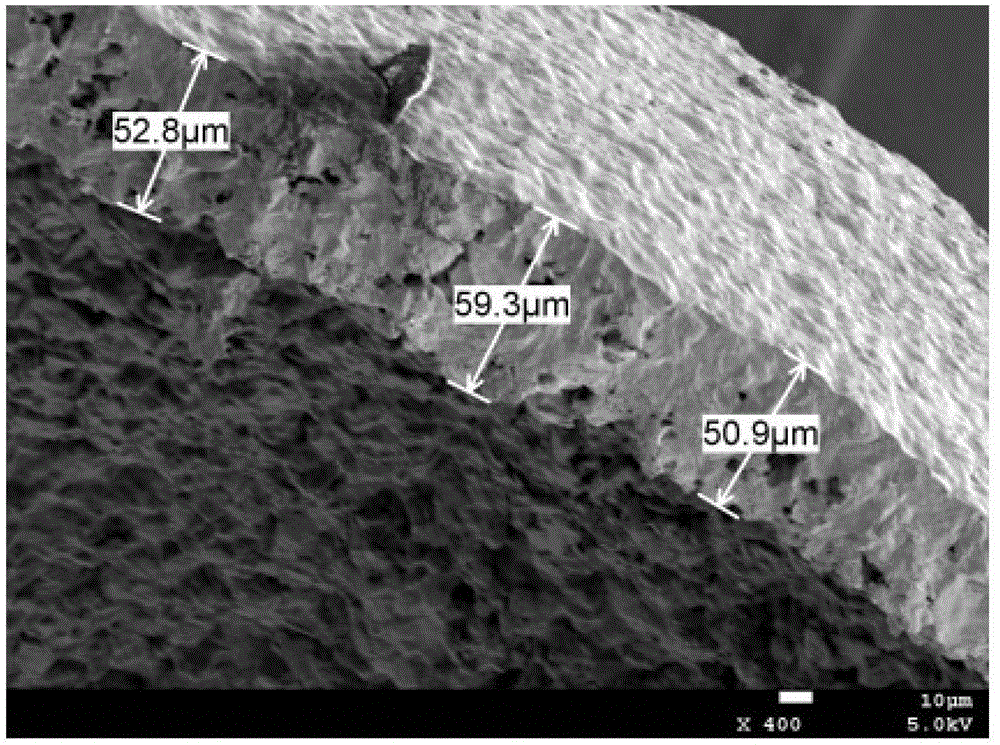

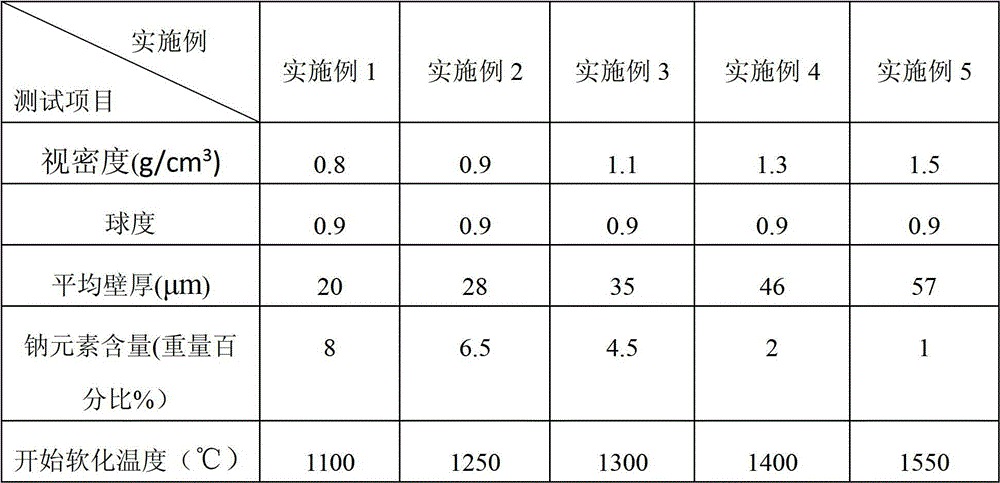

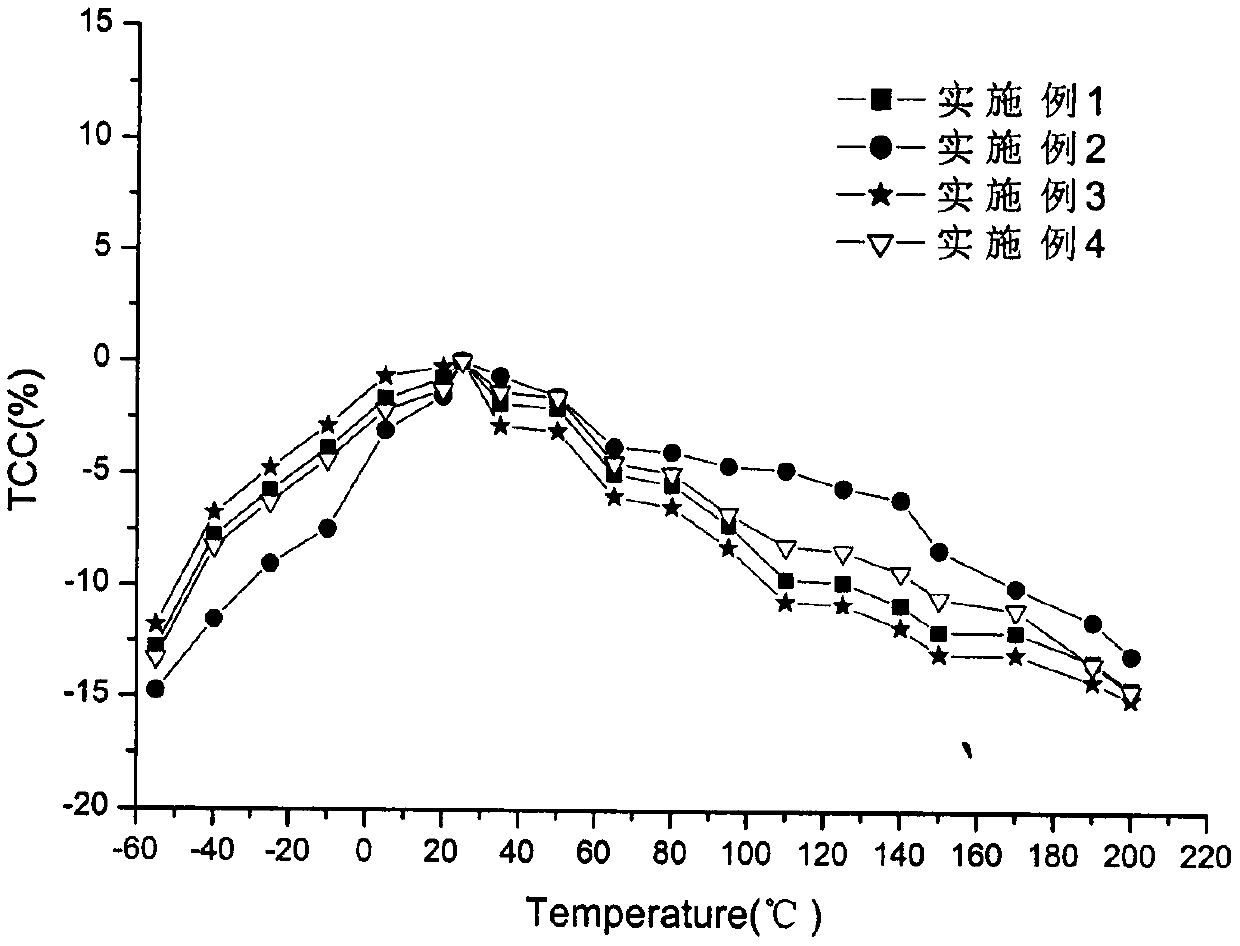

The invention relates to a SiO2-Al2O3 hollow ceramic ball and a preparation method thereof. The hollow ceramic ball is mainly composed of three elements of silicon, aluminum and oxygen and contains a small amount of the element of sodium, and the elements form silicon oxide, aluminum oxide and mullite; and the outer diameter of the ball is 0.04-0.8mm, the true density is 0.7-1.7g / cm<3>, the wall thickness is 5-70 mu m, and the static-pressure strength is 60-120 MPa. The preparation method comprises the following steps: sequentially adding 1-10 parts by weight of alpha-Al2O3 or pyrophyllite and 1-5 parts by weight of urea into 20-35 parts by weight of sodium silicate, stirring at a high speed until the raw materials are uniformly distributed, granulating, prefiring, performing acid washing to remove sodium, and sintering at high temperature to obtain the hollow ceramic ball. The hollow ceramic ball is lower in density, hollowed-out, better in sphericity, bigger in wall thickness, higher in fire resistance and higher in strength, thus being a novel light-weight refractory material and a low-density proppant. Besides, the preparation method is simple to operate, and the raw materials are wide in source.

Owner:SOUTHWEST PETROLEUM UNIV

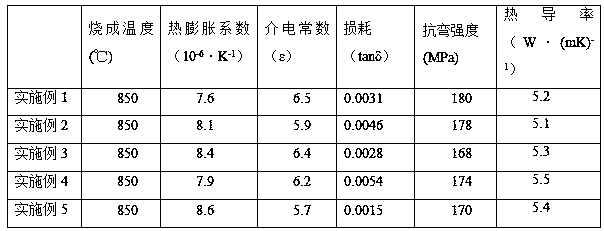

Low-temperature co-fired ceramic dielectric material and preparation method thereof

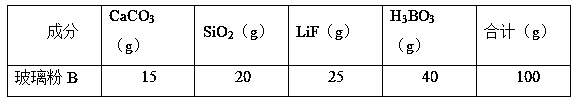

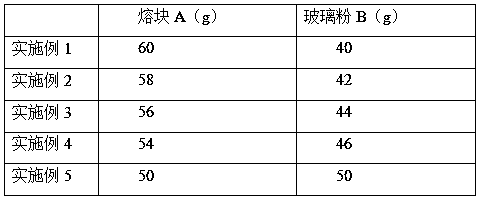

The invention discloses a low-temperature co-fired ceramic dielectric material and a preparation method thereof and relates to a substrate material of a communication component. The ceramic dielectricmaterial comprises 40-50% by weight of glass powder and 50-60% by weight of xAl2O3-2Nb2O5-ZnO, wherein x is in a range of 4-7; the glass powder is composed of CaCO3, SiO2, LiF and H3BO3. According tothe invention, an Al2O3-2Nb2O5-ZnO system is selected, then the glass powder is added as a sintering aid, and the sintering manner of heating to 400-500 DEG C and then to 850-900 DEG C and preservingheat for 0.5-1.5 hours is adopted; and thus, the a ceramic dielectric is obtained after cooling. The sintered ceramic substrate material of the invention has a complex chemical and crystal structure;the sintering temperature of the material is allowed to be lower than 1,000 DEG C via the method of the invention; and the ceramic dielectric material with a low dielectric constant, low dielectric loss, high strength and high thermal conductivity is formed at the same time.

Owner:TAIYUAN NORMAL UNIV

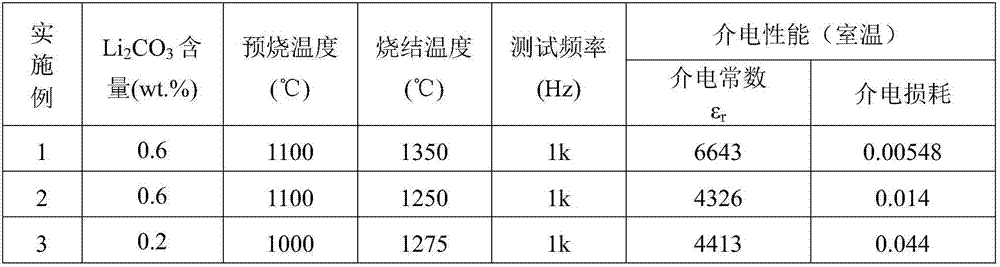

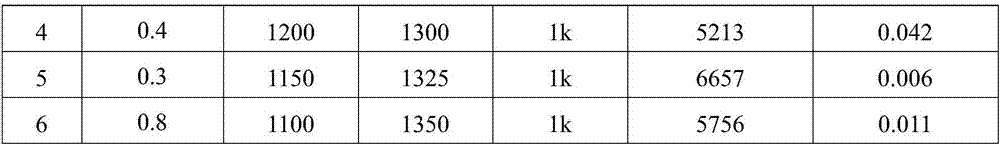

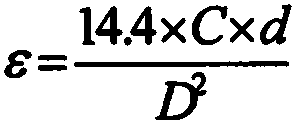

Barium zirconate titanate ceramic material with low dielectric loss and preparation method thereof

The invention discloses a barium zirconate titanate ceramic material with low dielectric loss. The chemical formula of the barium zirconate titanate ceramic material is Ba0.9Ca0.1Ti0.8Zr0.2O3+0.2-0.8wt.% Li2CO3 and is abbreviated as BCTZL. A preparation method of the barium zirconate titanate ceramic material includes: preparing BaCO3, CaCO3, TiO2 and ZrO2 according to the stoichiometric formula Ba0.9Ca0.1Ti0.8Zr0.2O3, performing ball milling, drying and sieving, pre-sintering at 1000-1200 DEG C, mixing the pre-sintered powder with 0.2-0.8wt.% Li2CO3, performing ball milling in a ball milling tank, drying, sieving, performing compression molding to obtain a green body, and sintering the green body at 1250-1325 DEG C to obtain the barium zirconate titanate ceramic material with low dielectric loss. The barium zirconate titanate ceramic material and the preparation method thereof have the advantages that the dielectric loss of the material is low and reaches 0.00548, the high dielectric constant of the material is high and reaches 6643, the sintering temperature (1250-1325 DEG C) of the preparation method is moderate, and the material can meet the needs, for constantly developing towards low power consumption, of electronic devices.

Owner:TIANJIN UNIV

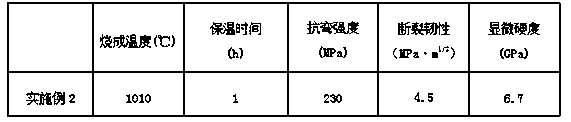

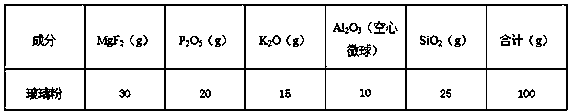

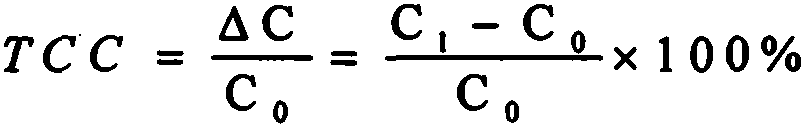

Machineable ceramic material and preparation method thereof

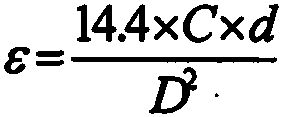

The invention provides a machineable ceramic material and a preparation method thereof. The material is prepared from 70%-90% by mass of glass powder, 5%-20% by mass of nano-diatomite and 1%-10% by mass of ZrO2; the glass powder is prepared from components in percentage by mass as follows: 15%-30% of MgF2, 5%-20% of P2O5, 5%-15% of K2O, 5%-10% of Al2O3 (hollow microspheres) and 25%-40% of SiO2. According to the material, the nano-diatomite is added as a modifier and is uniformly dispersed in a glass phase, and self-toughening and strengthening functions of fiber are realized. The machineable ceramic material has low sintering temperature, and the bending strength and breaking tenacity are improved.

Owner:TAIYUAN UNIV OF TECH

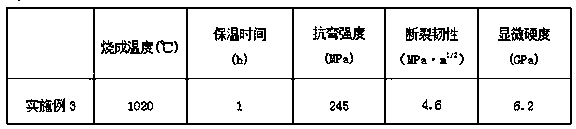

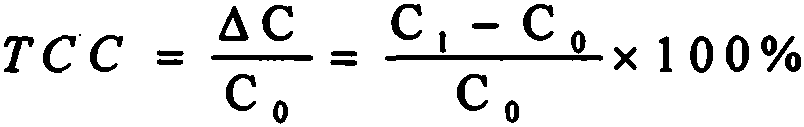

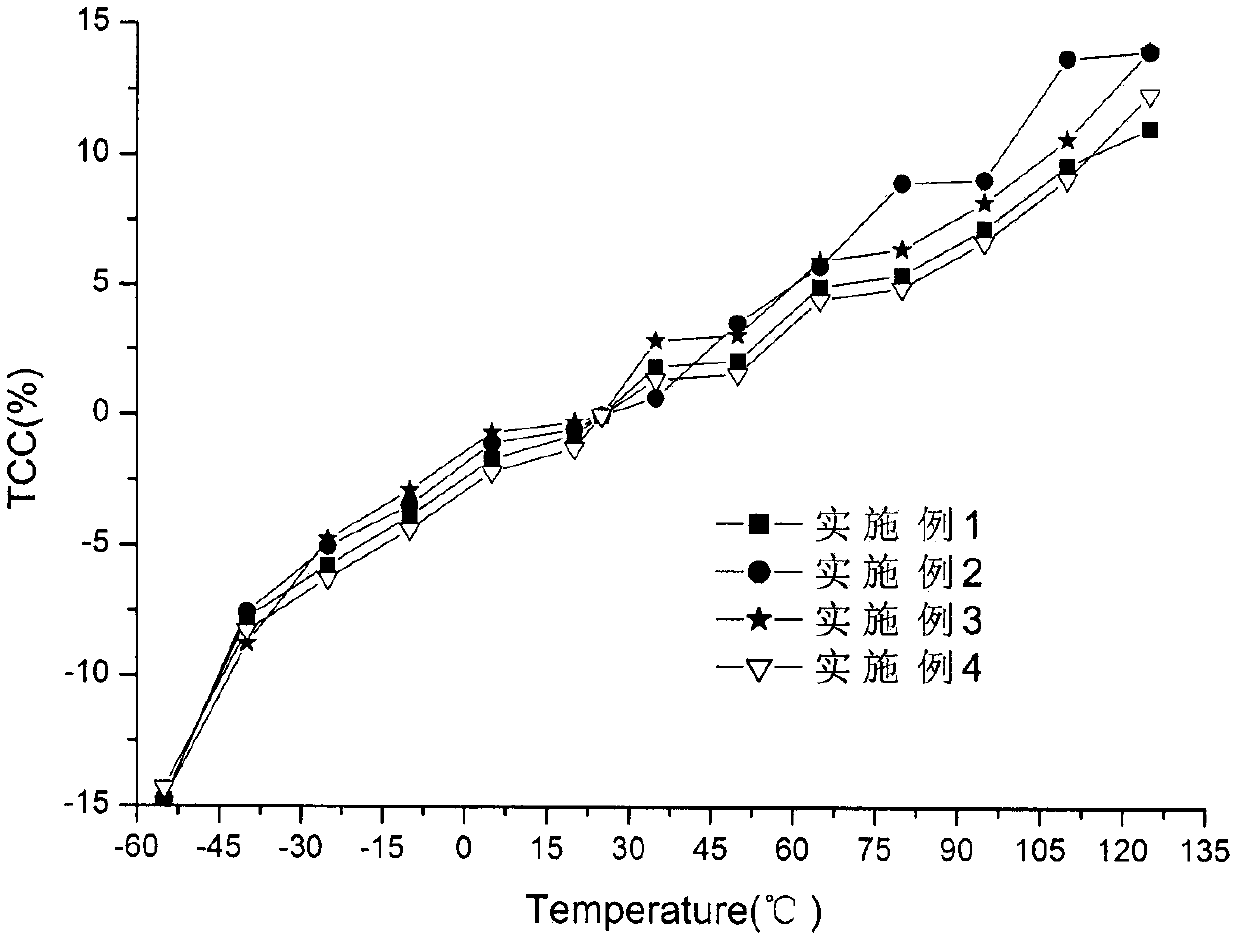

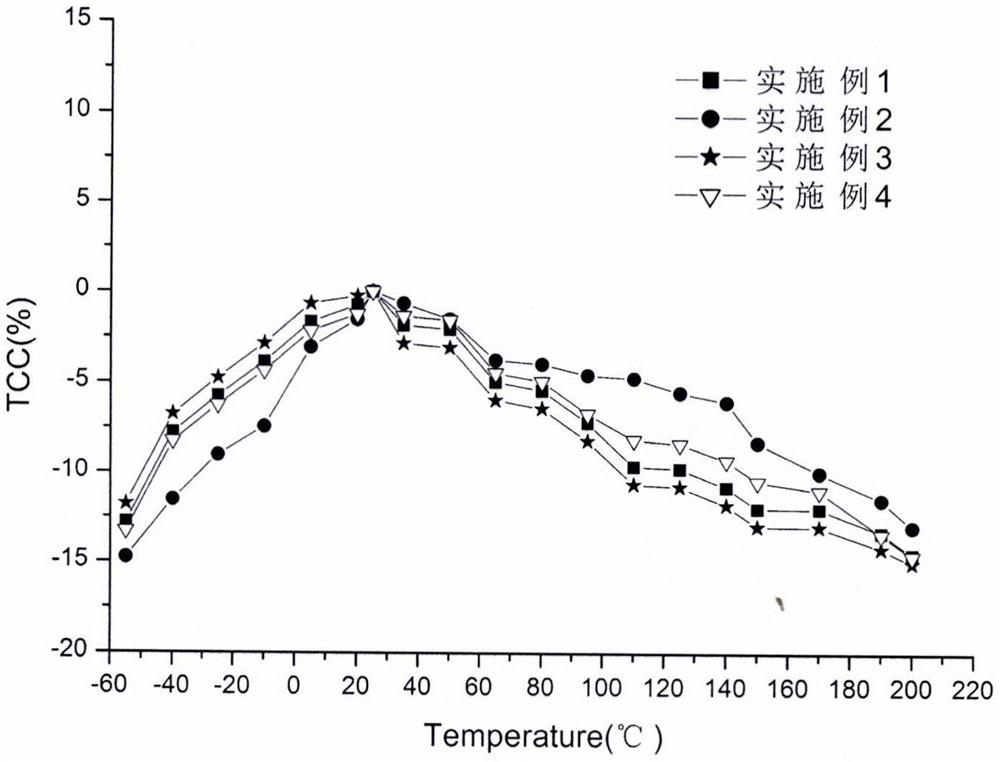

Temperature stable type high temperature ceramic capacitor medium material, and preparation method thereof

InactiveCN110498682AStable Relative PermittivityLow dielectric lossFixed capacitor dielectricPolyvinyl alcoholMetallurgy

The invention provides a temperature stable type high temperature ceramic capacitor medium material, and a preparation method thereof, and belongs to the technical field of ceramic capacitor material.The chemical formula of the temperature stable type high temperature ceramic capacitor medium material is 0.995(K<0.5>Na<0.5>)NbO<3>-0.005LaBiO<3>. The preparation method comprises following steps: araw material powder is dried and weighted accurately according to the stoichiometric ratio; ball milling is carried out to obtain a slurry; the slurry is dried, and grinded into powder, and is subjected to pressing into a cylindrical body, and the formed cylindrical body is subjected to pre-sintering; after pre-sintering, grinding is carried out to obtain a powder, ball milling is carried out toobtain a slurry material, the slurry material is dried and grinded into a powder material, a polyvinyl alcohol aqueous solution is taken as a binder for granulation, and pressing is carried out to obtain a cylindrical sample product, and at last high temperature degluing and sintering are carried out to obtain a finished product. The material is high and stable in relative dielectric constant, andlow in dielectric loss; technology is simple; cost is relatively low; sintering temperature is moderate; the raw material contains no toxic substance; and the high temperature application prospect ispromising.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Dielectric layer lead-less glasses material for plasma display screen

The invention discloses a lead-free glass frit for the dielectric layer of a plasma display, and the glass frit comprises the following raw materials according to the weight percentage: 30%-50% of Bi2O3, 5%-40% of B2O3, 5%-30% of BaO, 0.1%-10% of Al2O3, 0.1%-10% of ZnO, 0.1%-10% of MgO and0.1%-5% of La2O3. The invention has the advantages that the glass frit belongs to environment-friendly materials; various performances are excellent; the cost performance is high; the glass frit has suitably and easily adjusted thermal expansion coefficient and proper sintering temperature, and also has good chemical stability and high dielectric strength; the competitive power is very strong in lead-free performance and cost performance; and the glass frit has wide market development prospect.

Owner:陈培

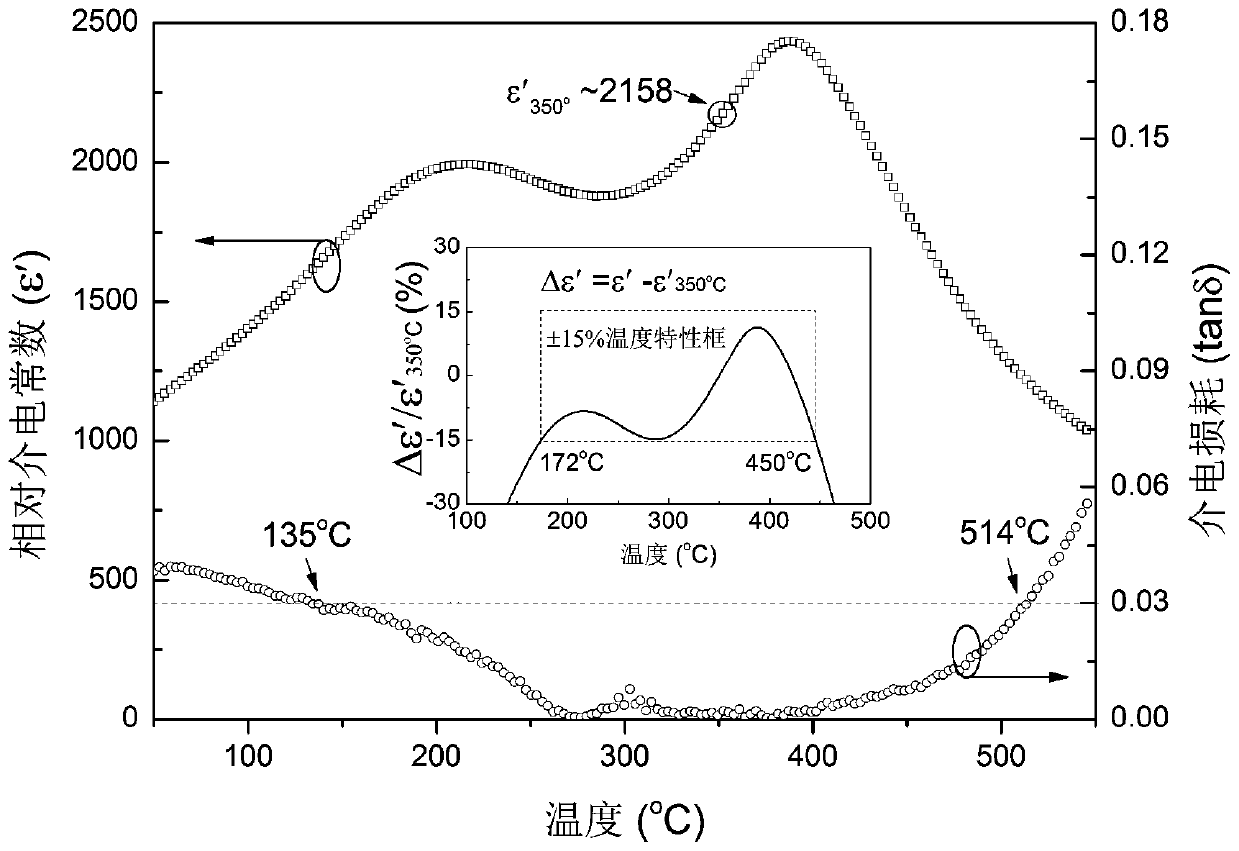

Method for preparing wear-resisting netty Cr3C2 reinforced NiAl alloy

The invention discloses a method for preparing a wear-resisting netty Cr3C2 reinforced NiAl alloy. The wear-resisting netty Cr3C2 reinforced NiAl alloy is prepared from Ni powder, Al powder, Cr powderand Ni covered graphite powder through ball milling and the SPS sintering technology. The alloy prepared through the method is simple in structure, and a three-dimensional netty Cr3C2 ceramic reinforced phase is constructed in a NiAl intermetallic compound matrix of an isometric crystal structure. The method is simple in process operation and low in cost, the prepared material has high yield strength and excellent wear resistance at the temperature of room temperature to 800 DEG C, and wide industrial application prospects are achieved.

Owner:青岛市资源化学与新材料研究中心 +1

A preparation method and application of a back electrode of a solar cell

ActiveCN109004043ALow costReduce unit consumptionPhotovoltaic energy generationElectrically-conductive paintsSilver pastePull force

The invention discloses a preparation method and application of a back electrode of a solar cell, which comprises two parts, a back electrode barrier layer and a back silver paste. 20 to 80 part of metal nitride powder, nitrogen-silicon compound powder, oxide powder or low-melting-point metal powder, 0.5 to 5 parts of lead-free glass powder, 10 to 40 parts of organic carrier and 0.1 to 1 part of organic assistant. 10-80 part of silver powder, 0. 5-5 parts of lead-free glass powder, 15-50 parts of organic bind and 0. 01-1 part of organic assistant. The present invention ensures that it has considerable welding pulling force and aging pulling force, avoids serious electric leakage problem caused by metal defects caused by direct contact between silver and silicon wafer or aluminum paste, improves photoelectric conversion efficiency of crystalline silicon battery, adjusts back electrode width and printed pattern, and reduces back electrode paste cost.

Owner:NANTONG T SUN NEW ENERGY CO LTD

High-dielectric X8R ceramic dielectric material and preparation method thereof

The invention relates to the field of ceramic dielectric materials, in particular to a high-dielectric X8R ceramic dielectric material and a preparation method thereof. The material consists of the following components in percentage by weight: 5-20 % of Sc2O3 and 80-95 % of K2Sr4Nb6O20. According to the high-dielectric X8R ceramic dielectric material provided by the invention, the K2Sr4Nb6O20 series of dielectric ceramic has moderate sintering temperature which is generally around 1250 DEG C, has relatively high dielectric constant, adjustable capacity temperature coefficient and low loss, andis a dielectric ceramic material with excellent performance. A K2Sr4Nb6O20 system is selected, and a doping modification method of adding the Sc2O3 is adopted, so that the K2Sr4Nb6O20 system meets the performance X8R standard, and has the advantages of high dielectric constant, low dielectric loss, lead-free and environment-friendly.

Owner:TAIYUAN UNIV OF TECH

Heat-insulating wear-resistant inner wallboard

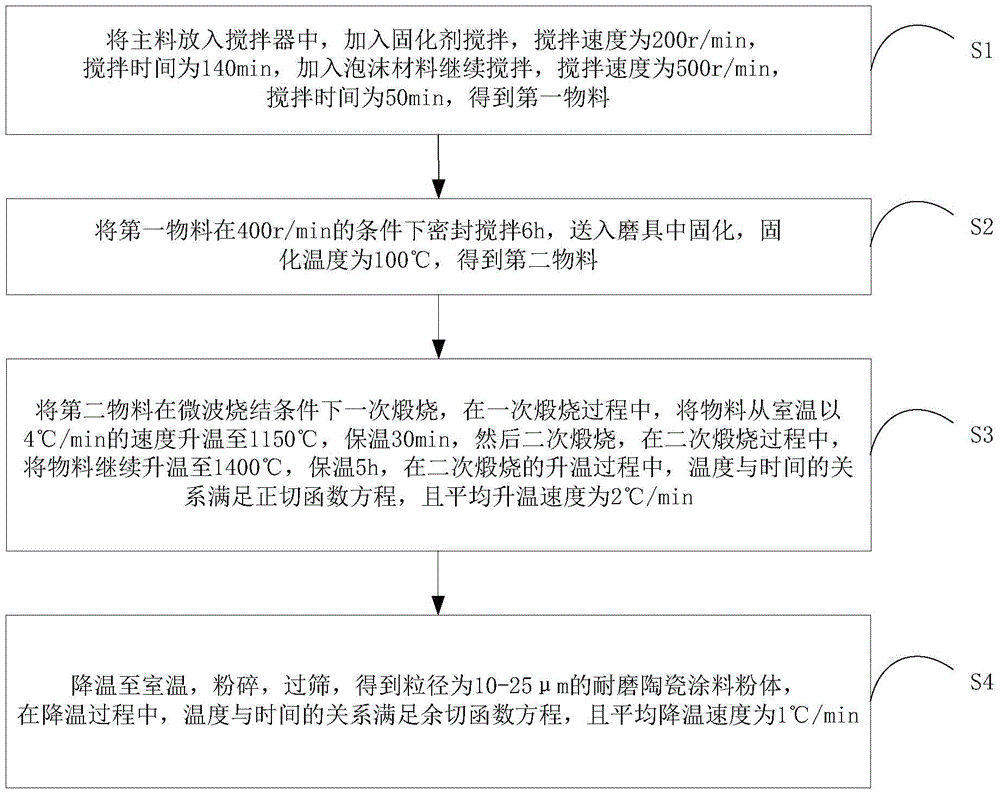

InactiveCN105113705AHigh strengthGood grinding performanceBuilding componentsCeramicwareFiberPolyethylene oxide

The invention discloses a heat-insulating wear-resistant inner wallboard comprising a base layer, a binding layer, a heat insulating layer, a fireproof layer, a waterproof layer, a latex layer and a wear-resistant layer which are arranged sequentially from inside to outside. The wear-resistant layer is made of a ceramic material, raw materials of the ceramic material include main materials, curing agent and a foaming material, raw materials of the main material include cement, micropowder, steel fiber, phosphate tailings, zirconium dioxide, feldspar, shale, kaolin, aluminum oxide, water, sodium hexametaphosphate, sodium tripolyphosphate and sodium humate, raw materials of the curing agent include propylene glycol alginate, locust bean gum, Arabic gum, silica sol, sodium silicate and polyethylene oxide, and raw materials of the foaming material include surfactant, foam stabilizer, rosin soap, sodium carboxymethylcellulose and sodium dodecyl sulfate. The heat-insulating wear-resistant inner wallboard is high in wear resistance and excellent in heat insulativity.

Owner:ANHUI MINGYUAN NEW BUILDING MATERIAL TECH CO LTD

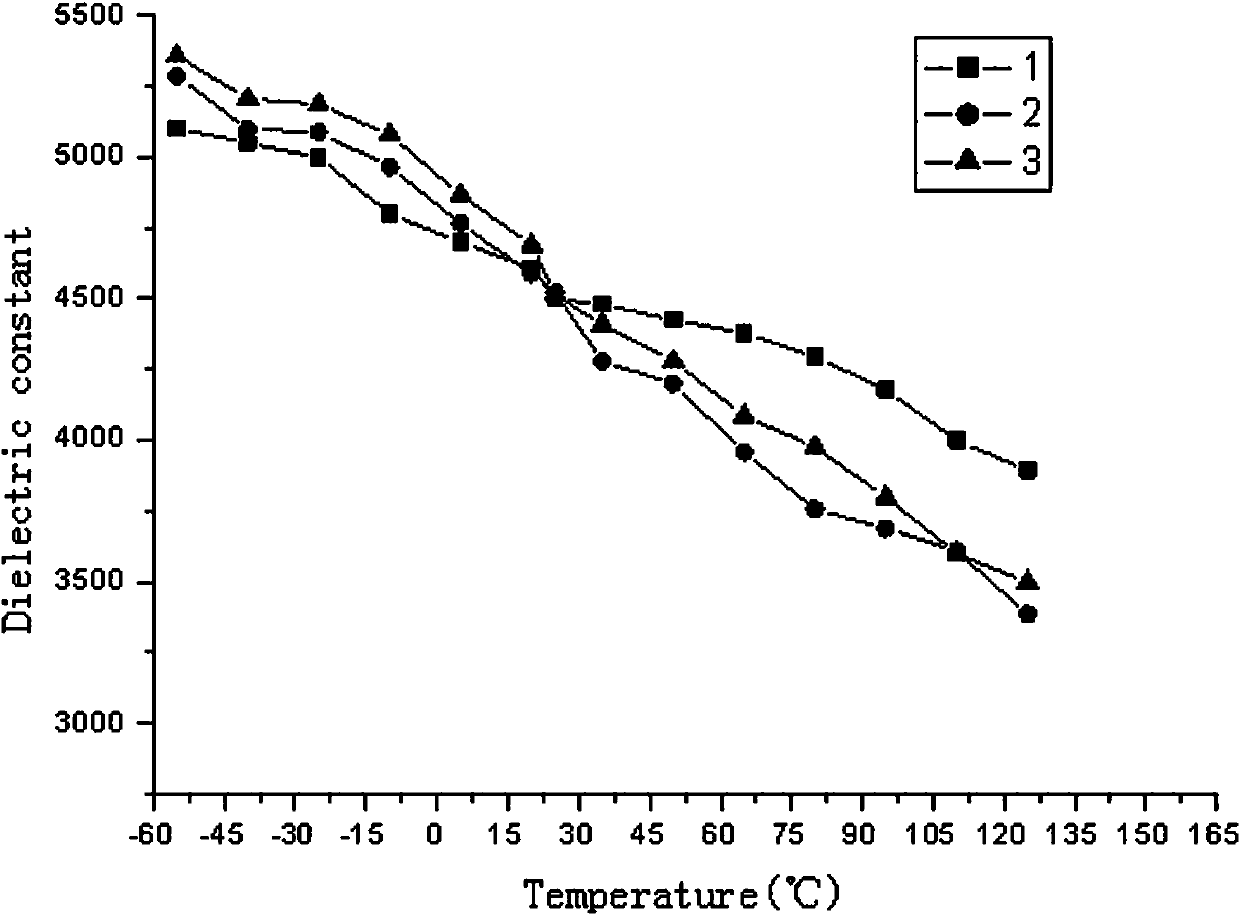

Low temperature co-fired ceramic dielectric material and preparation method thereof

ActiveCN110156457AHigh dielectric constantLow temperature coefficient of capacityCo-fired ceramicDielectric loss

The invention discloses a low temperature co-fired ceramic dielectric material and a preparation method thereof. The material comprises the following raw materials: in percent by mass, 5-20% of glasspowder and 80-95% of Ca0.95La0.05Cu2.8Zn0.2Ti4O12, wherein the glass powder includes the following raw materials: in percent by mass, 5-40% of Li2CO3, 5-30% of ZnO, 5-30% of BaCO3, 5-30% of CaCO3 and5-30% of kaolin. The preparation method of the low temperature co-fired ceramic dielectric material comprises the steps: weighing the raw materials according to the stoichiometric ratio of the general formula for proportioning so as to obtain a frit A, mixing, in percent by mass, 5-20% of the glass powder B and 80-95% of the frit A, performing ball milling, adding an adhesive, performing granulation, performing heat preservation at 800-850 DEG C for 1 hour, and performing cooling so as to obtain the low temperature co-fired ceramic dielectric material. The ceramic dielectric material has a low sintering temperature, a high dielectric constant and low dielectric loss, and can be co-fired with a high-conductivity silver metal internal electrode.

Owner:TAIYUAN NORMAL UNIV

High-dielectric X7R ceramic dielectric material and preparation method thereof

The invention relates to the field of ceramic dielectric materials, in particular to a high-dielectric X7R ceramic dielectric material and a preparation method thereof. The material is prepared from,by mass, 5-25% of Nd2O3 and 75-95% of Ca0.95La0.05Cu2.55Zn0.5Ti4O12. According to the high-dielectric X7R ceramic dielectric material, Ca0.95La0.05Cu2.55Zn0.5Ti4O12 dielectric ceramics have a moderatesintering temperature which is always about 1130 DEG C, and are high in dielectric constant, adjustable in capacity temperature coefficient and low in loss. The material is a dielectric ceramic material with excellent performance. A Ca0.95La0.05Cu2.55Zn0.5Ti4O12 system is selected, and the method of adding Nd2O3 for doping and modification is utilized, so that the material has the advantages of being high in dielectric constant, low in dielectric loss, free of lead and environmentally friendly while the performance X7R standard is met.

Owner:TAIYUAN NORMAL UNIV

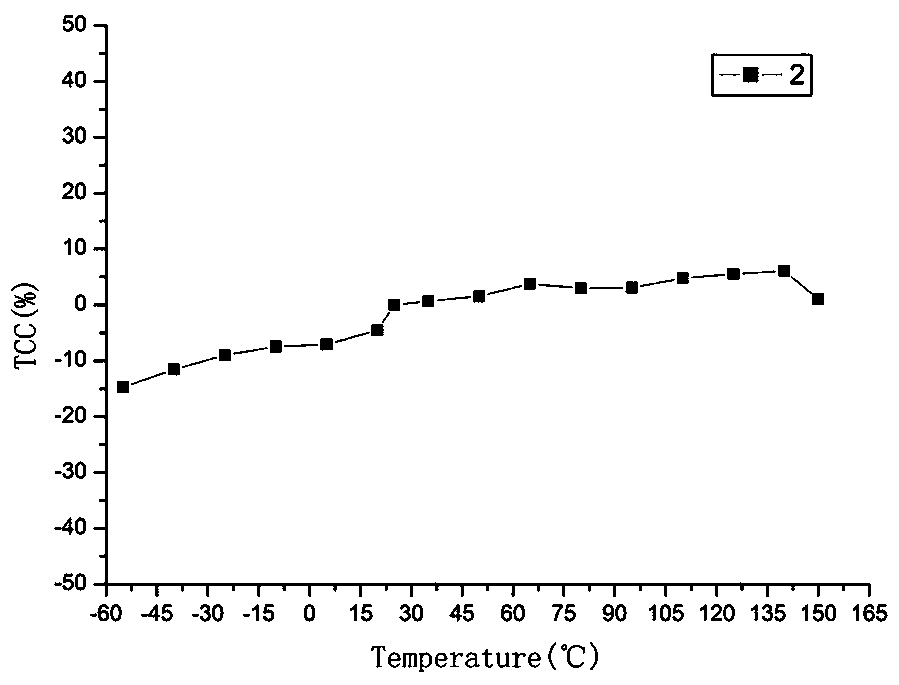

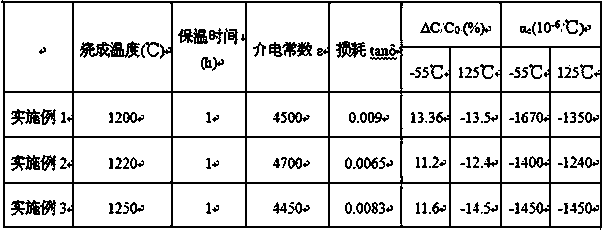

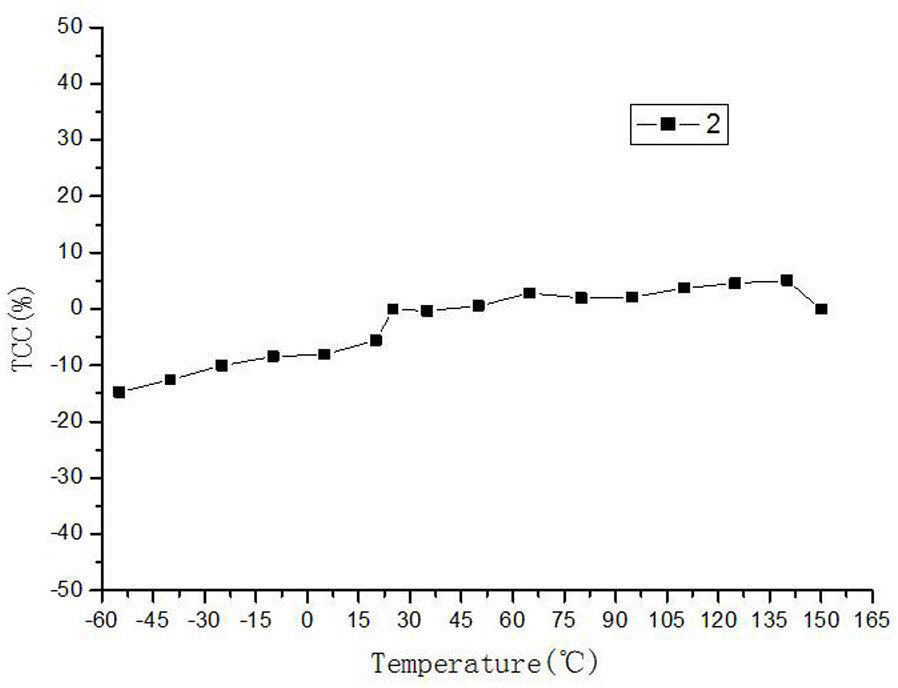

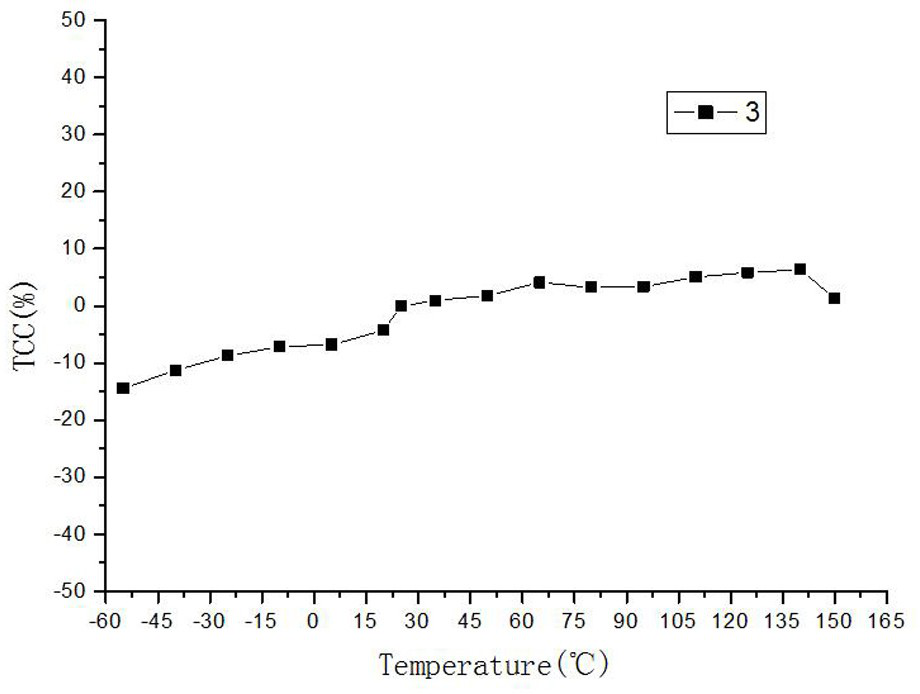

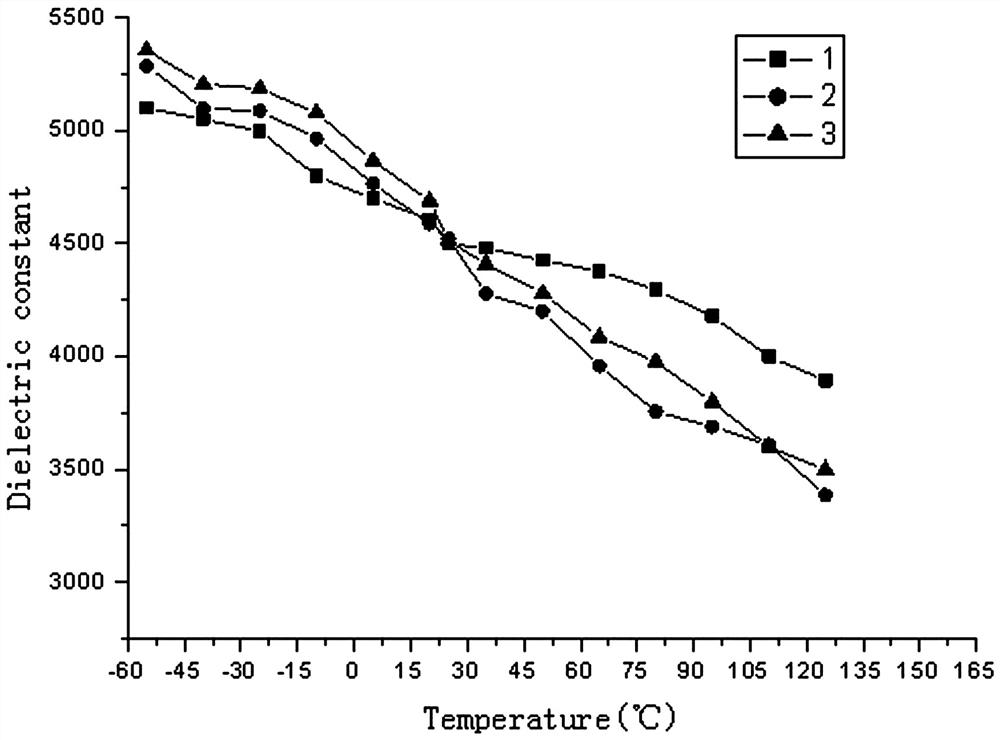

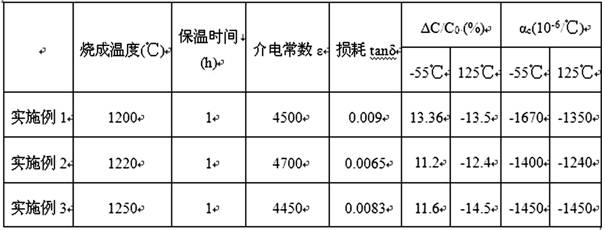

Ceramic dielectric material with negative temperature coefficient and preparation method thereof

The invention belongs to the technical field of ceramic dielectric materials, and provides a ceramic dielectric material with a negative temperature coefficient and a preparation method thereof in order to prevent the capacitance of a capacitor from increasing due to a temperature rise or other factors in the use process of the capacitor and improve the reliability. The ceramic dielectric materialcomprises 10-30wt% of CaTiO3 and 70-90wt% of K2Sr4 (Nb8Mg2) O27. The ceramic dielectric material meets the EIAX7R standard, the capacitance change rate in the temperature range of 55 DEG C to 125 DEGC does not exceed + / -15%. The ceramic dielectric material has a good dielectric property, the dielectric constant can reach about 4700 at the temperature of 25 DEG C, and the loss is 0.0065. The ceramic dielectric material has a negative capacitance temperature coefficient, compensates for the increase of capacitance caused by the temperature rise or other factors, and improves the reliability. The ceramic dielectric material has the advantages of wide sintering temperature range, adjustable performances, good stability and reproducibility, high reliability, and environmental friendliness, moreover, the ceramic dielectric material does not contain any harmful substances such as heavy metal.

Owner:TAIYUAN NORMAL UNIV

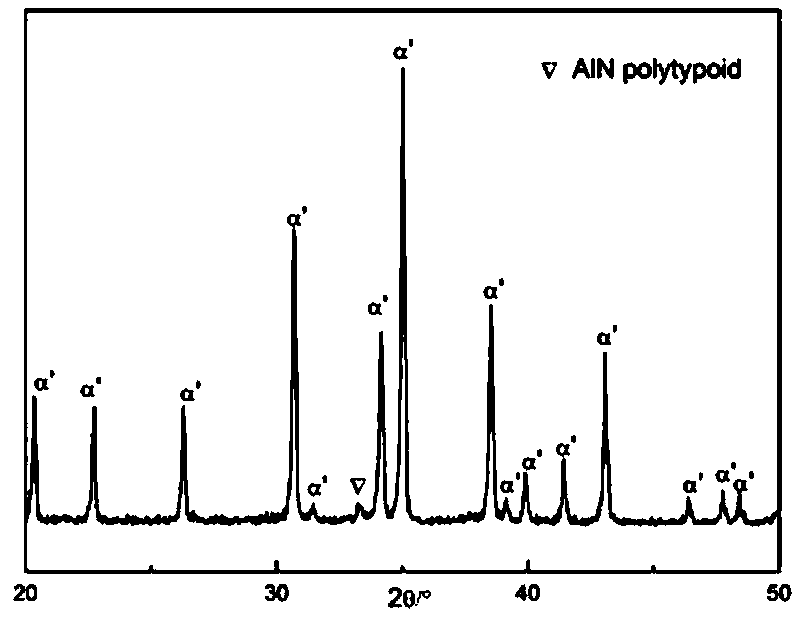

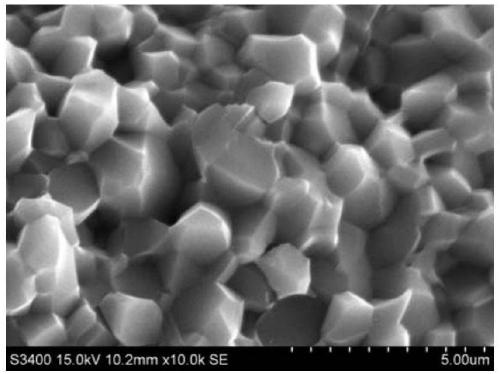

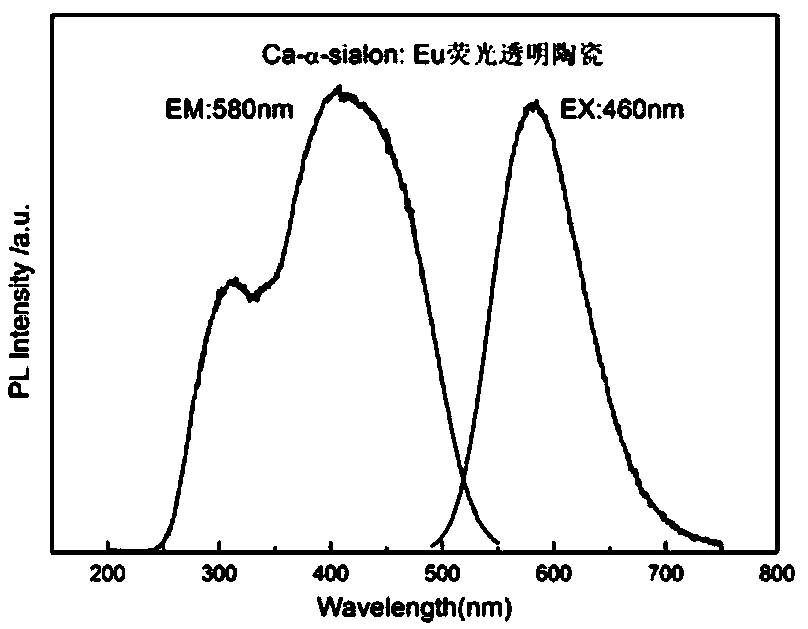

High-power warm-white light solid illumination SiAlON fluorescent transparent ceramic and preparation method thereof

ActiveCN109020558ASimple processGood repeatabilityEnergy efficient lightingLuminescent compositionsBroadband transmissionFluorescence

The invention relates to high-power warm-white light solid illumination SiAlON fluorescent transparent ceramic and a preparation method thereof, wherein the method includes: 1) according to the general formula of Ca<m / 2-x-yv / 2>Si<12-m-n>Al<m+n>O<n>N<1>6-n: xEu<2+>, yM<v+>, wherein v refers to chemical valence, 0.8 <= m <= 2.0, 1.0 <= n <= 2.0, 0 < x <= m / 4 and 0 <= y <= m / 2v-2x / v, mixing alpha-Si3N4, AlN, alpha-Al2O3, CaCO3, Eu2O3 and a raw material containing M to form a mixture A, and adding a mixture B with mixing, wherein the mixture B includes AlN and alpha-Si3N4, the mass of the mixtureB is 5-50% of the mixture A and the weight ratio of the Si3N4 to AlN in the mixture B is 0-5:1; 2) ball-milling and drying the mixture and sintering the mixture through hot pressed sintering or sparkplasma sintering to obtain a sintered product; 3) cutting and grinding the sintered product and polishing the sintered product to a mirror surface, thus obtaining Ca-alpha-sialon: Eu<2+> fluorescent transparent ceramic, which has broadband transmission under activation by blue light, is 570-600 nm in main wavelength and is adjustable in wavelength. The method has simple process and good repeatability. The fluorescent transparent ceramic has high heat conductivity and excellent heat quenching performance, and is suitable for high-power warm-white light solid illumination.

Owner:ANHUI UNIV OF SCI & TECH

Low-temperature co-fired ceramic medium material and preparation method thereof

InactiveCN101823877BModerate sintering temperatureImprove performanceMetallic electrodeDielectric loss

The invention discloses a low-temperature co-fired ceramic medium material. The material consists of 1 to 16 weight percent of glass powder and 84 to 99 weight percent of Ba6-3x(Nd0.4Bi0.6)8+2xTi18O54, wherein the x is 0.5 to 1.5. The glass powder is at least one of the following two types of glass powder, namely glass powder B consisting of 30 to 50 mass percent of Li2CO3 and 5 to 20 mass percent of SiO2 and 40 to 60 mass percent of H3BO3 and glass powder C consisting of 15 to 40 mass percent of LiF and 60 to 85 mass percent of BaF2. In a preparation process, first, clinker is prepared; then, secondary preparation of the glass powder and the clinker is performed; and finally, sintering is performed. A BaO-Nd2O3-Bi2O3-TiO2 system is selected and a method of adding the glass powder as a sintering aid is adopted, so the material has the characteristics of sintering temperature below 900 DEG C, high dielectric constant and low dielectric loss, simultaneously has a wide sintering shrinkage range, and can be co-fired with a silver metallic electrode with high conductivity.

Owner:TIANJIN UNIV

A kind of high dielectric X8R ceramic dielectric material and preparation method thereof

The invention relates to the field of ceramic dielectric materials, in particular to a high-dielectric X8R ceramic dielectric material and a preparation method thereof. is composed of 5‑20% by weight Sc 2 o 3 and 80‑95% by weight of K 2 Sr 4 Nb 6 o 20 consist of. High dielectric X8R ceramic dielectric material provided by the present invention, K 2 Sr 4 Nb 6 o 20 The dielectric ceramic has a moderate sintering temperature, generally around 1250°C, a high dielectric constant, adjustable capacity temperature coefficient and low loss, and is a dielectric ceramic material with excellent performance. The present invention chooses K 2 Sr 4 Nb 6 o 20 system, take the addition of Sc 2 o 3 The method of doping modification makes it meet the performance X8R standard, and at the same time has the advantages of high dielectric constant, low dielectric loss, lead-free and environmental protection.

Owner:TAIYUAN UNIV OF TECH

A kind of high dielectric X7r ceramic dielectric material and preparation method thereof

InactiveCN110105067BHigh dielectric constantImprove performanceCeramicsDielectric lossDielectric ceramics

The invention relates to the field of ceramic dielectric materials, in particular to a high-dielectric X7R ceramic dielectric material and a preparation method thereof. It is composed of Nd with a mass percentage of 5‑25% 2 o 3 and 75‑95% Ca 0.95 La 0.05 Cu 2.55 Zn 0.5 Ti 4 o 12 consist of. High dielectric X7R ceramic dielectric material provided by the present invention, Ca 0.95 La 0.05 Cu 2.55 Zn 0.5 Ti 4 o 12 The dielectric ceramic has a moderate sintering temperature, generally around 1130°C, a high dielectric constant, adjustable capacity temperature coefficient and low loss, and is a dielectric ceramic material with excellent performance. The present invention selects Ca 0.95 La 0.05 Cu 2.55 Zn 0.5 Ti 4 o 12 system, take the addition of Nd 2 o 3 The method of doping modification makes it meet the performance X7R standard, and at the same time, it has the advantages of high dielectric constant, low dielectric loss, lead-free and environmental protection.

Owner:TAIYUAN NORMAL UNIV

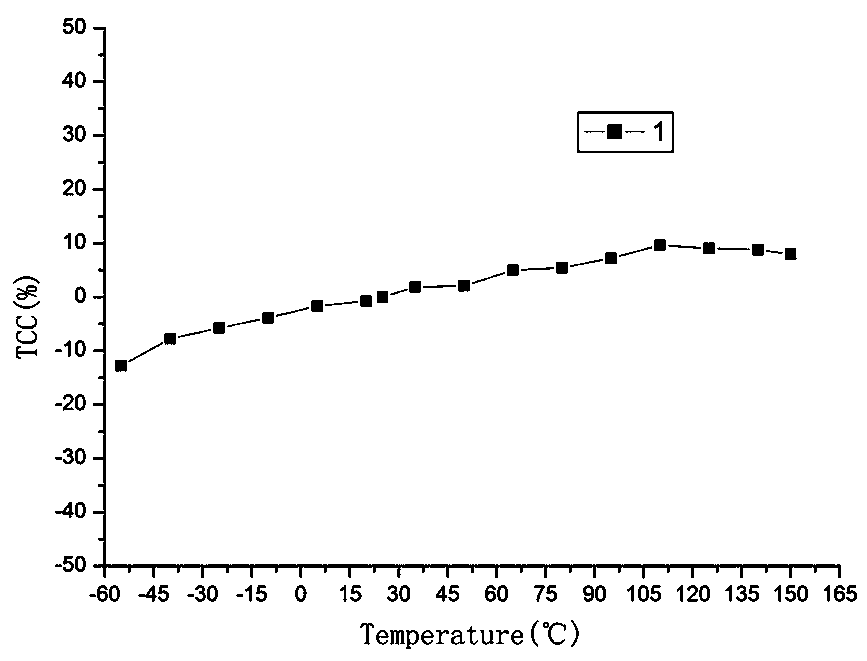

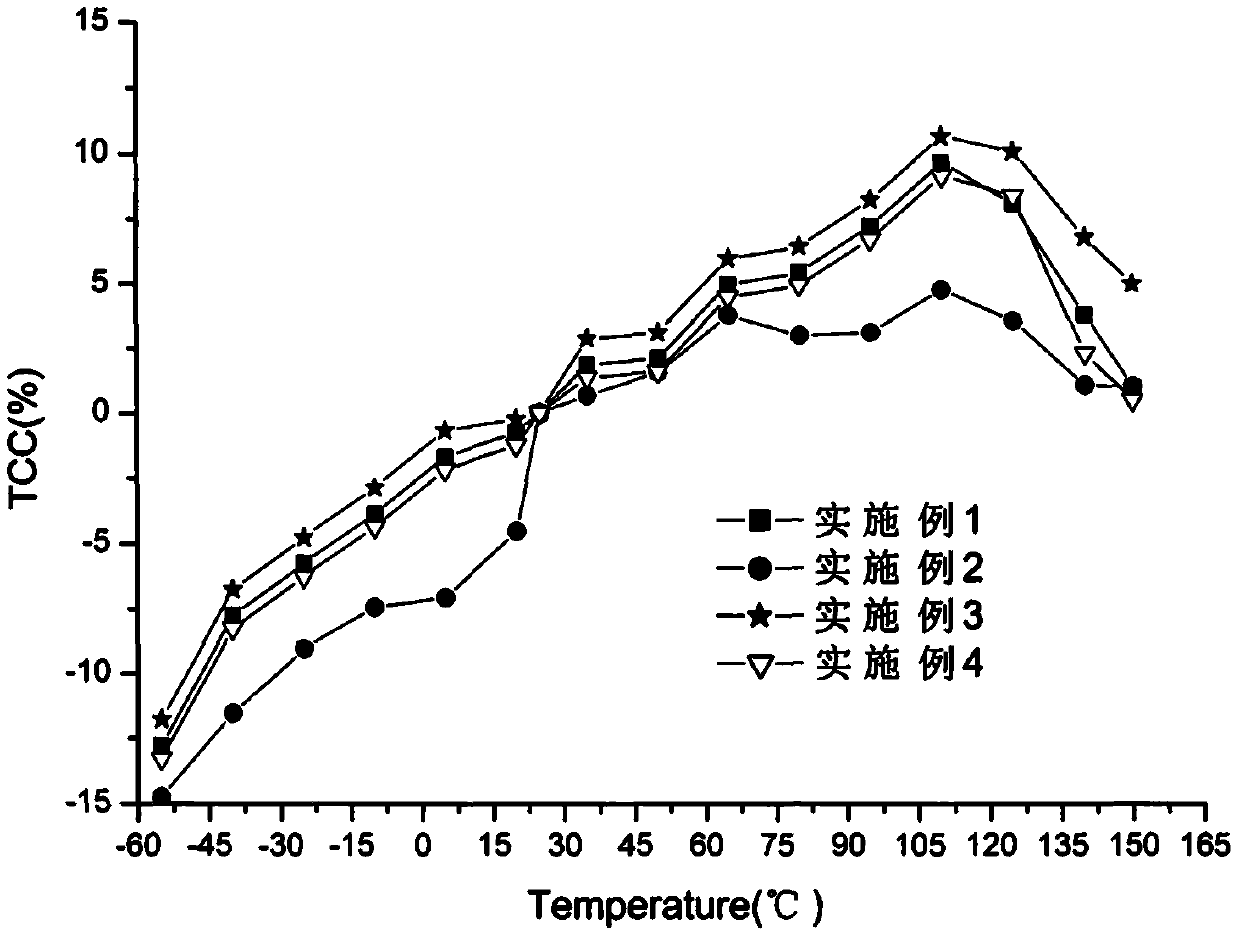

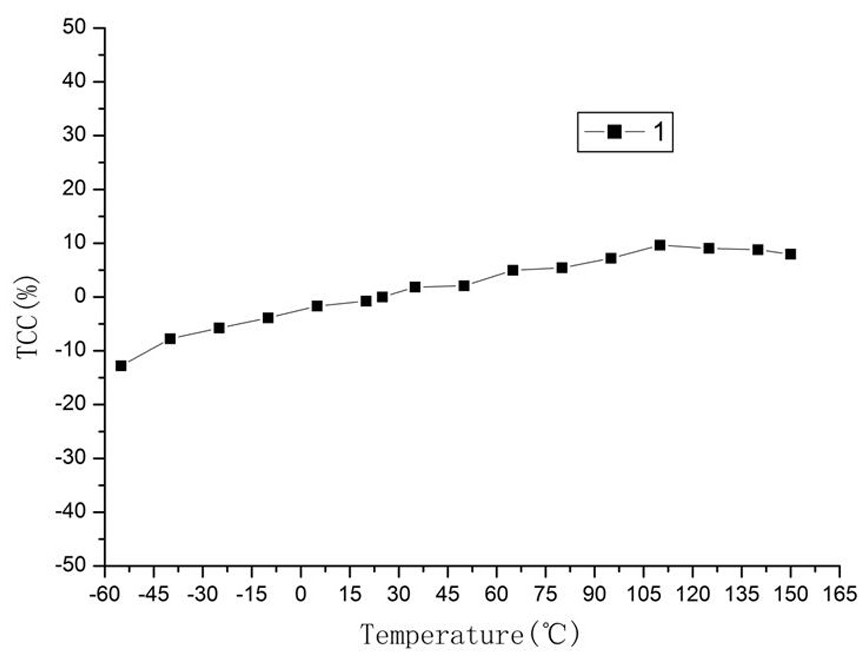

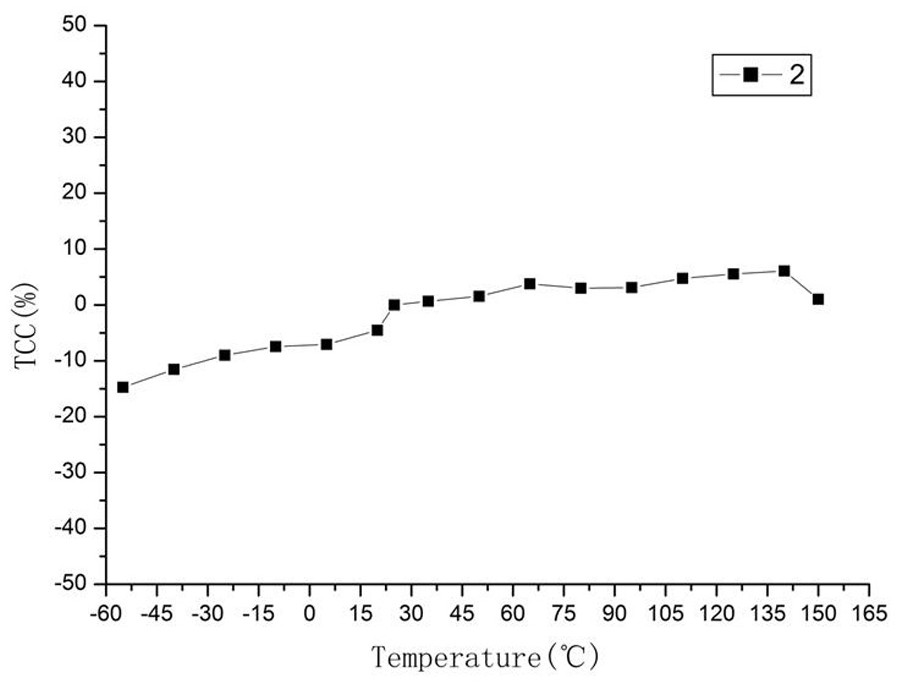

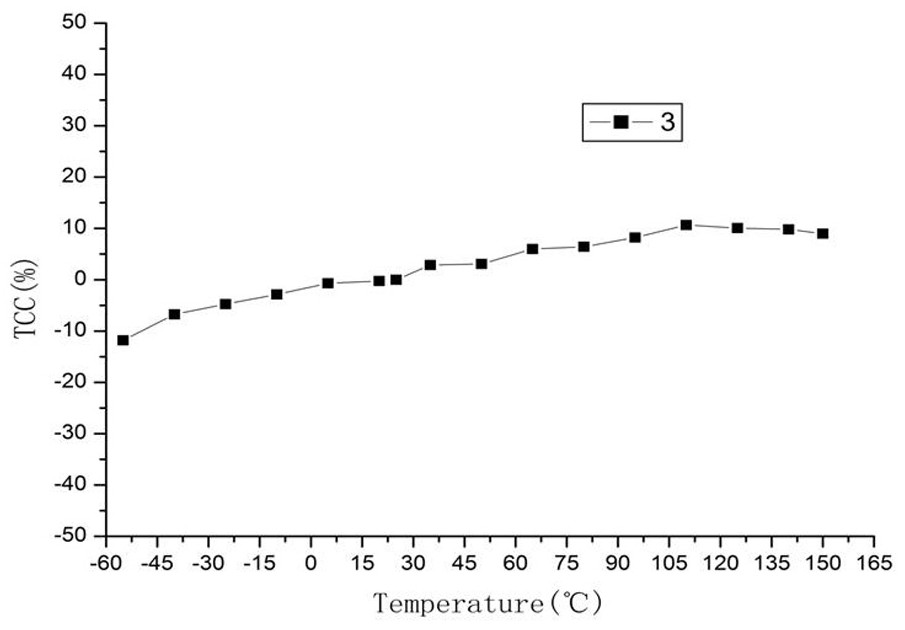

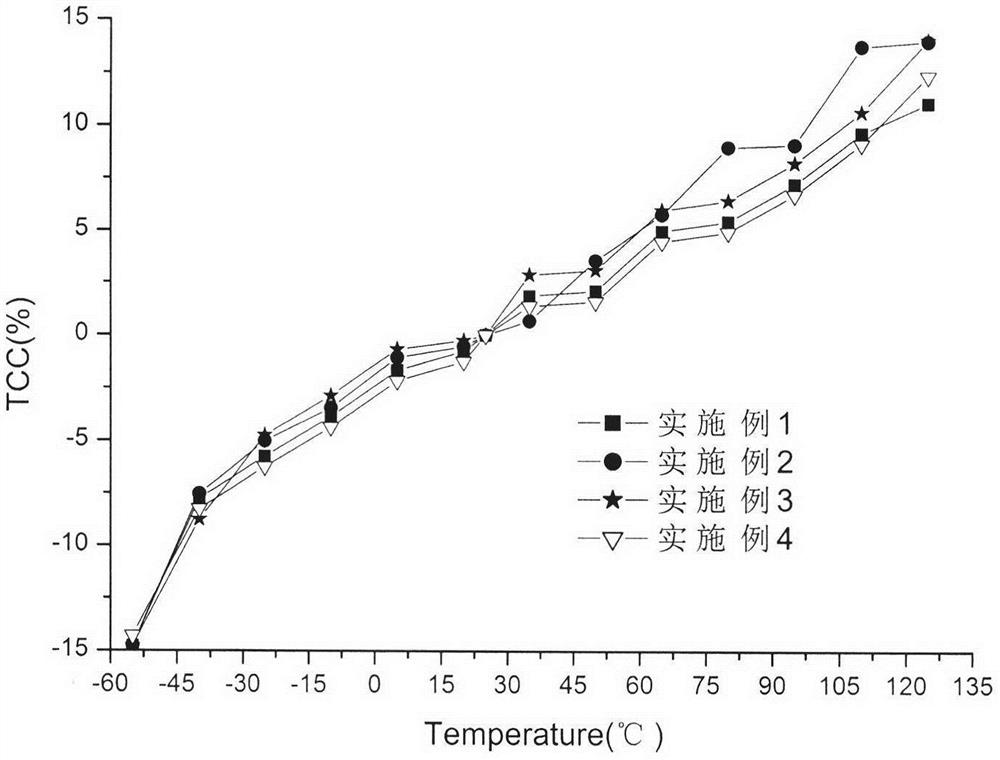

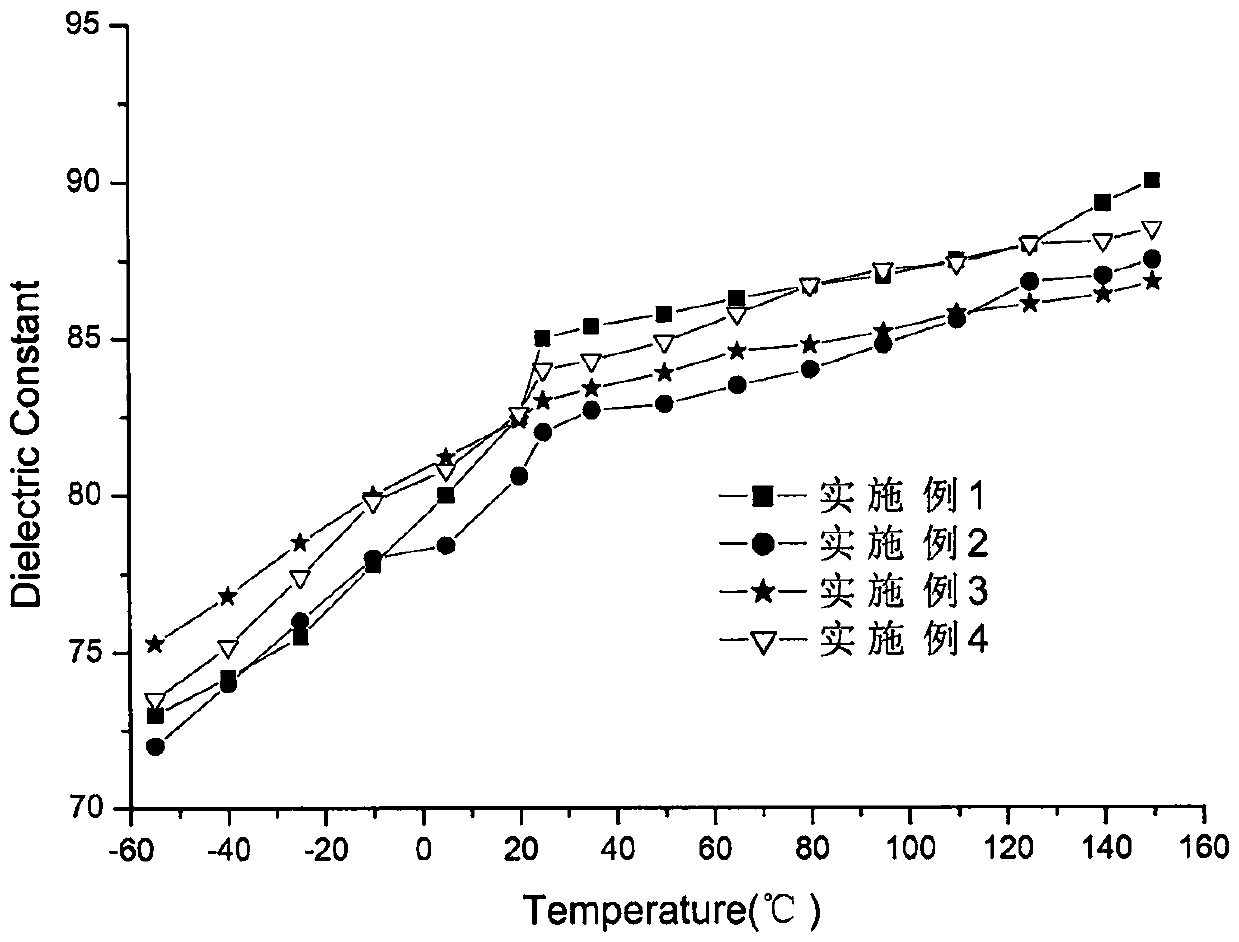

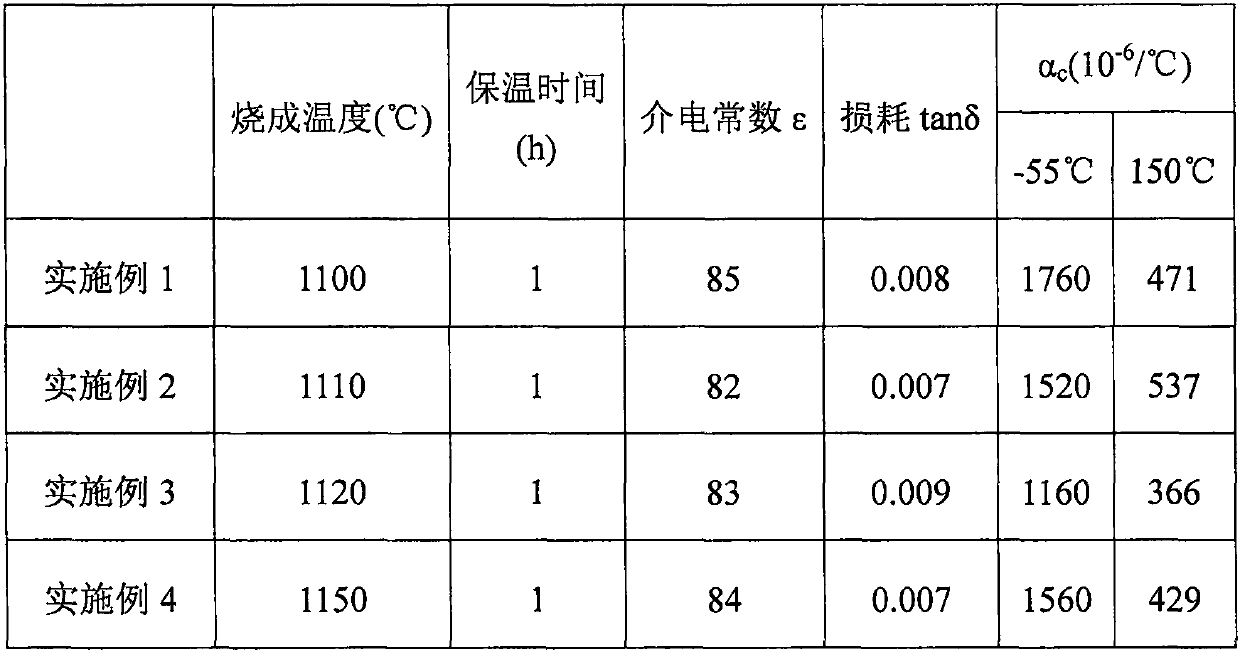

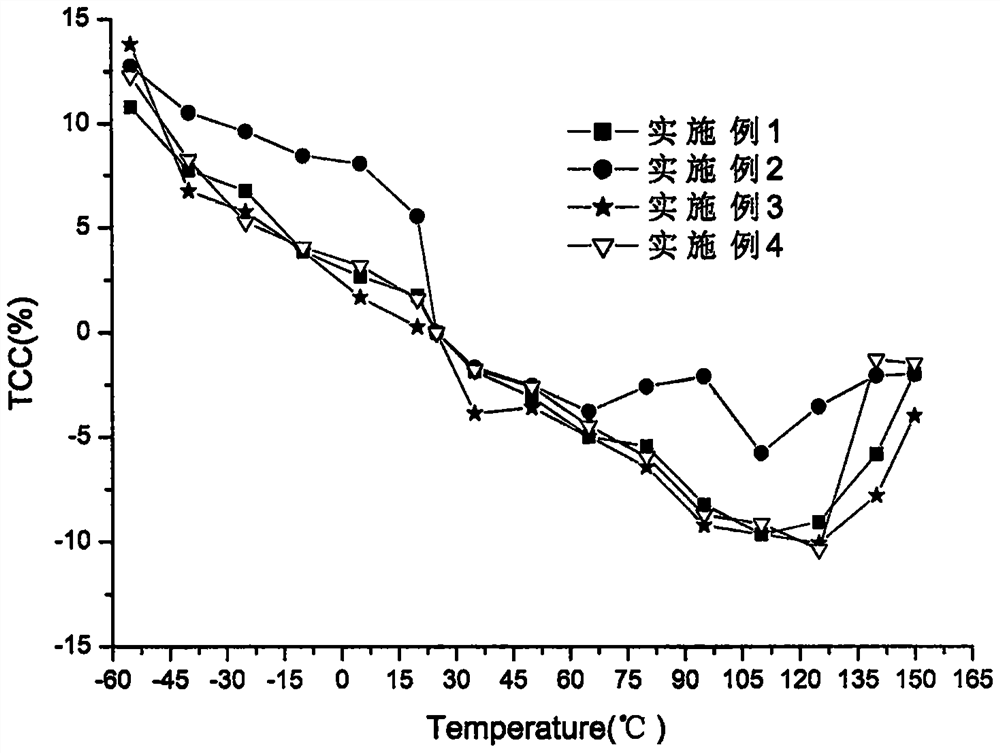

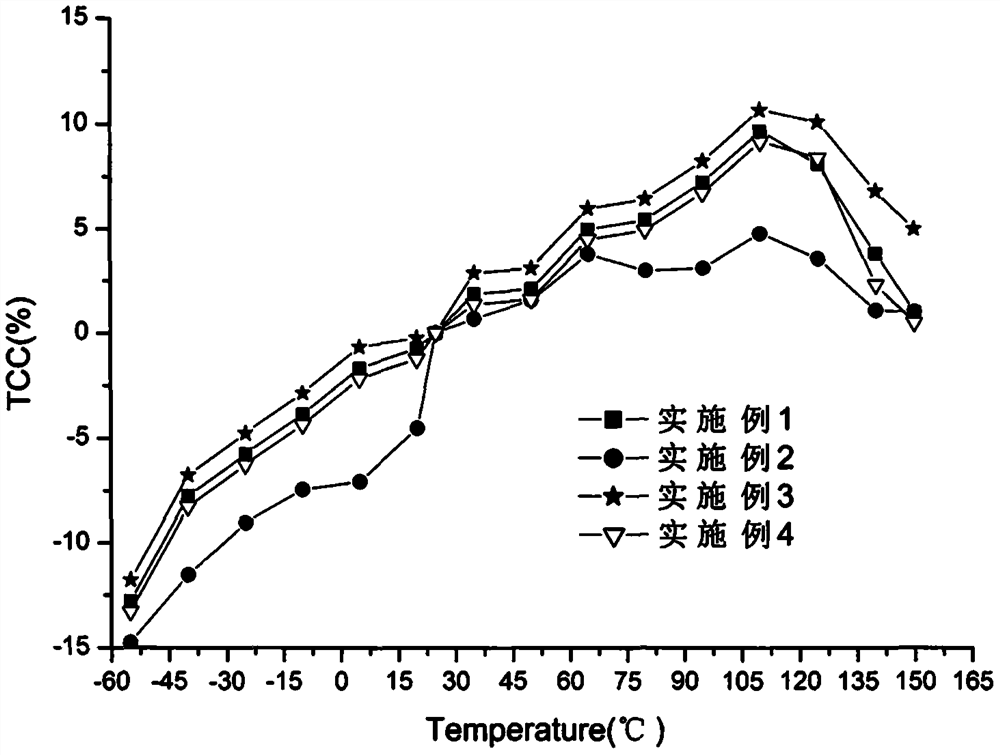

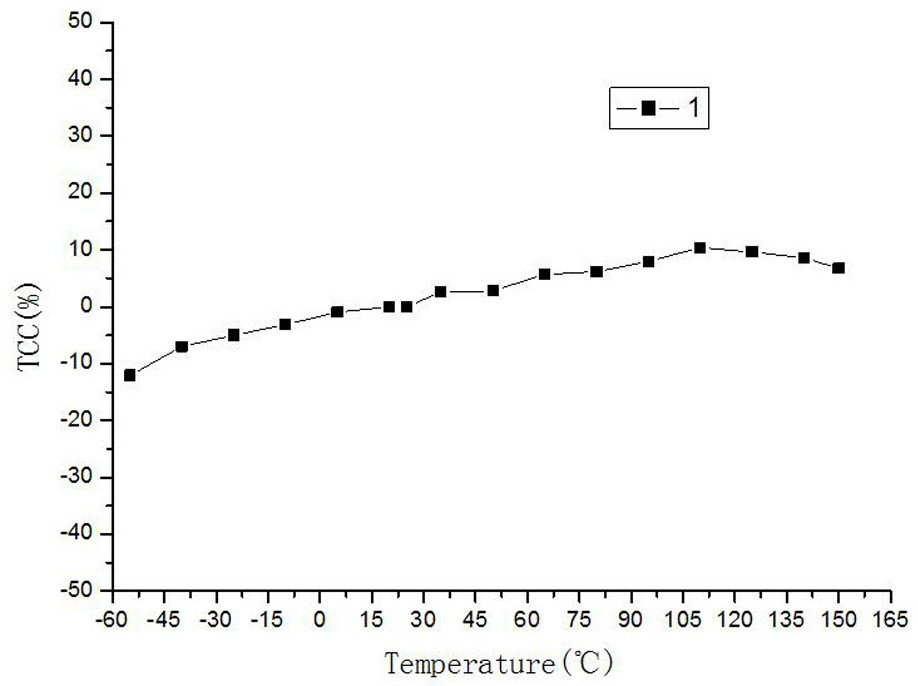

Positive-temperature-coefficient ceramic dielectric material and preparing method thereof

InactiveCN110066172AModerate sintering temperatureHigh dielectric constantFixed capacitor dielectricStacked capacitorsCapacitanceDielectric loss

The invention belongs to the technical field of ceramic dielectric materials, and provides a positive-temperature-coefficient ceramic dielectric material and a preparing method thereof in order to solve the problem that a capacitance temperature coefficient of an existing ceramic dielectric material is positive or negative and continuously changes within the range from -55 DEG C to 150 DEG C. Theceramic dielectric material is prepared from, by mass, 80-90% of Na0.2Bi0.6ZrO3 and 10-20% of Yb2O3. The ceramic dielectric material has the advantages of high dielectric constant, low in dielectric loss and positive temperature coefficient. The material Na0.2Bi0.6ZrO3 has a perovskite structure and has no Curie peak within the range from -55 DEG C to 150 DEG C, Na+ and Bi3+ can be stably fixed after Yb2O3 is dopted, and the ceramic dielectric material has a positive capacitance temperature coefficient within the range from -55 DEG C to 150 DEG C.

Owner:TAIYUAN NORMAL UNIV

Dielectric layer lead-less glasses material for plasma display screen

The present invention discloses a lead-free glass frit for the dielectric layer of a plasma display, and the glass frit comprises the following raw materials according to the weight percentage: 30%-50% of Bi2O3, 5%-40% of B2O3, 5%-30% of BaO, 0.1%-10% of Al2O3, 0.1%-10% of ZnO, 0.1%-10% of MgO and0.1%-5% of La2O3. The invention has the advantages that the glass frit belongs to environment-friendly materials; various performances are excellent; the cost performance is high; the glass frit has suitably and easily adjusted thermal expansion coefficient and proper sintering temperature, and also has good chemical stability and high dielectric strength; the competitive power is very strong in lead-free performance and cost performance; and the glass frit has wide market development prospect.

Owner:陈培

Preparation method of low-temperature-sintering chip-type voltage dependent resistor material

InactiveCN106554199ALow varistor voltageHigh nonlinear coefficientElectrical resistance and conductanceNano sio2

A preparation method of a low-temperature-sintering chip-type voltage dependent resistor material includes the following steps: (1) raw material preparation: preparing the raw materials including, on the basis of 100 parts by weight, 1-3 parts of ZrO2, 2-5 parts of FeCl2, 1-2 parts of Fe3O4, 1-2 parts of Fe2O3, 1-3 parts of AlCl3, 1-4 parts of nano Cr2O3, 2-5 parts of nano SiO2, 2-5 parts of Mn2O3, and the balanced being ZnO; (2) mixing the raw materials and adding deionized water, performing wet-milling for 48-50 h and drying the mixture at 140-160 DEG C; (3) under the pressure of 5-8 MPa, shaping the mixture into small round chips being 20 mm in diameter [Phi] and being 1.4-1.8 mm in thickness, and sintering the chips in air and naturally cooling the chips to room temperature; and (4) sinter-coating the two surfaces of the sintered ceramic body with silver. The chip-type voltage dependent resistor has low varistor voltage, high non-linear coefficient and stable voltage-dependent characters, is moderated in sintering temperature, has simple and controllable produce technology, and is low in cost.

Owner:蒋宏伟

Microwave ceramic dielectric material and preparation method thereof

ActiveCN114538926AImprove performanceModerate sintering temperatureChemical industryDielectric lossDielectric permittivity

The invention discloses a microwave ceramic dielectric material and a preparation method thereof. The microwave ceramic dielectric material comprises the following raw materials in percentage by mass: 60-80% of Li < 1.19 > Ta < 0.81 > Ti < 0.19 > O < 3 >, 25-20% of TiO < 5 >, 5-20% of Ta2O < 5 >, 5-20% of Mn2O < 5 > and 5-20% of glass powder. The glass powder is prepared from the following raw materials in percentage by mass: 25 to 40 percent of CaF, 5 to 30 percent of P2O5, 5 to 30 percent of CaCO and 5 to 40 percent of AlF. The ceramic dielectric material is low in sintering temperature, high in dielectric constant, low in dielectric loss and high in temperature stability.

Owner:TAIYUAN NORMAL UNIV

SiO2-Al2O3 hollow ceramic ball and preparation method thereof

The invention relates to a SiO2-Al2O3 hollow ceramic ball and a preparation method thereof. The hollow ceramic ball is mainly composed of three elements of silicon, aluminum and oxygen and contains a small amount of the element of sodium, and the elements form silicon oxide, aluminum oxide and mullite; and the outer diameter of the ball is 0.04-0.8mm, the true density is 0.7-1.7g / cm<3>, the wall thickness is 5-70 mu m, and the static-pressure strength is 60-120 MPa. The preparation method comprises the following steps: sequentially adding 1-10 parts by weight of alpha-Al2O3 or pyrophyllite and 1-5 parts by weight of urea into 20-35 parts by weight of sodium silicate, stirring at a high speed until the raw materials are uniformly distributed, granulating, prefiring, performing acid washing to remove sodium, and sintering at high temperature to obtain the hollow ceramic ball. The hollow ceramic ball is lower in density, hollowed-out, better in sphericity, bigger in wall thickness, higher in fire resistance and higher in strength, thus being a novel light-weight refractory material and a low-density proppant. Besides, the preparation method is simple to operate, and the raw materials are wide in source.

Owner:SOUTHWEST PETROLEUM UNIV

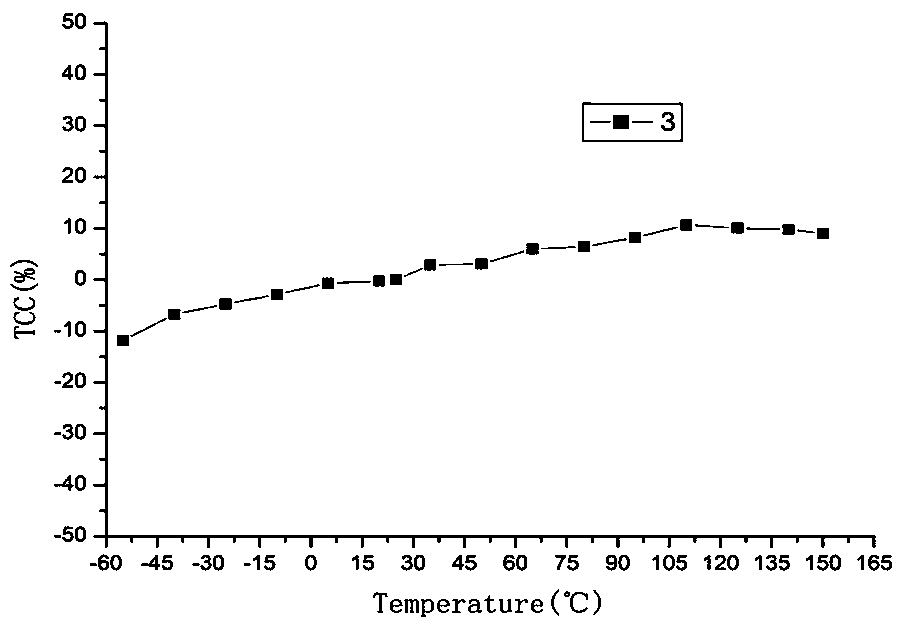

Temperature-stable ceramic dielectric material and preparation method thereof

ActiveCN110105065AHigh dielectric constantLow temperature coefficient of capacityTemperature coefficientDielectric loss

The invention relates to the field of ceramic dielectric materials, in particular to a temperature-stable ceramic dielectric material and a preparation method thereof. The material is prepared from, by mass, 5-20% of KNbO3, 10-20% of SrTiO3 and 70-85% of BiMg0.1Ti0.7O3. According to the temperature-stable ceramic dielectric material, the SrTiO3-BiMg0.1Ti0.7O3 dielectric ceramic has the moderate sintering temperature, generally at about 1,050 DEG C, the high dielectric constant, adjustable capacity temperature coefficient and low loss are achieved, and the dielectric ceramic material is excellent in performance. Accordingly, a SrTiO3-BiMg0.1Ti0.7O3 system is selected, the method of adding KNbO3 for doping modification is adopted, and the material has the advantages of being high in dielectric constant and low in dielectric loss while the temperature stability type is met.

Owner:TAIYUAN NORMAL UNIV

A temperature-stable ceramic dielectric material and its preparation method

Owner:TAIYUAN NORMAL UNIV

A kind of low temperature co-fired ceramic dielectric material and preparation method thereof

The invention discloses a low-temperature co-fired ceramic dielectric material and a preparation method thereof. The material includes the following raw materials in mass percentage: glass powder 5-20%, Ca 0.95 La 0.05 Cu 2.8 Zn 0.2 Ti4O 12 80‑95%. Described glass powder comprises the raw material of following mass percent: Li 2 CO 3 5‑40%, ZnO 5‑30%, BaCO 3 5‑30%, CaCO 3 5‑30% and Kaolin 5‑30%. The preparation method is as follows: the raw materials are weighed according to the stoichiometric ratio of the general formula, and the frit A is obtained; 5-20% glass powder B and 80-95% frit A are mixed and ball-milled according to the mass percentage, and the binder is added , granulation, heat preservation at 800-850°C for 1 hour, and cooling. The ceramic dielectric material has low sintering temperature, high dielectric constant and low dielectric loss, and can be co-fired with silver metal internal electrodes with high conductivity.

Owner:TAIYUAN NORMAL UNIV

A kind of machinable ceramic material and preparation method thereof

The present invention is a machinable ceramic material and a preparation method thereof, wherein the material comprises glass powder with a mass percentage of 70-90%, nano diatomite with a mass percentage of 5-20% and ZrO with a mass percentage of 1-10% 2 ; Described glass powder comprises the component of following mass percent: the MgF of 15-30% 2 , 5‑20% of P 2 o 5 , 5‑15% of K 2 O, 5‑10% Al 2 o 3 (hollow microspheres) and 25‑40% SiO 2 Composition of glass powder. The material adopts the method of adding nano-diatomite as a modifier, and the nano-diatomite is evenly dispersed in the glass phase to play the role of fiber self-toughening and strengthening. The sintering temperature of the machinable ceramic material of the invention is low, and the bending strength and fracture toughness are improved.

Owner:TAIYUAN UNIV OF TECH

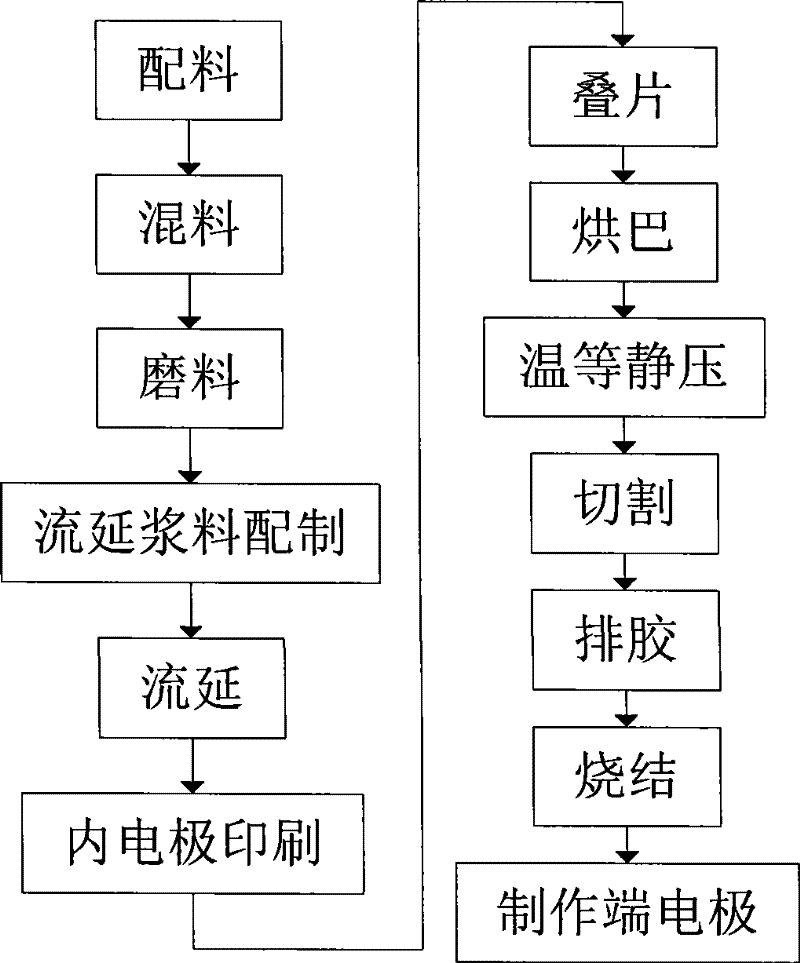

Voltage dependent resistor dielectric material of zinc oxide and method of manufacturing electrical resistor

InactiveCN101367649BLow varistor voltageHigh nonlinear coefficientVaristor coresResistive material coatingCooking & bakingDielectric

The invention relates to a zinc oxide voltage dependent resistor medium material and a resistor preparation method, which belongs to the technology field of electronic material. The components of the zinc oxide voltage dependent resistor medium material comprises 85 percent to 95 percent of ZnO, 2 percent to 6 percent of Bi2O3, 1 percent to 5 percent of TiO2, 1 percent to 3.5 percent of Sb2O3, 1 percent to 4 percent of MnCO3, 1.2 percent to 5 percent of Co2O3, 0.2 percent to 1 percent of Cr2O3, 0.1 percent to 1 percent of ZrO2, 0.2 percent to 1 percent of Ni2O3 and 1.2 percent to 3 percent ofSiO2. The chip type zinc oxide resistor preparation method comprises the steps of dosing according to a zinc oxide resistor medium material medium material, material mixing, material grinding, casting sizing agent making, casting, inner electrode printing, laminating, baking, temperature isostatic pressing, cutting, gule discharging, sintering, end electrode making, and the like. The zinc oxide voltage dependent resistor medium material of the invention is suitable for making chip type voltage dependent resistor; the prepared chip type voltage dependent resistor has the characteristics of low voltage-dependent voltage, high nonlinear coefficient and stable voltage-dependent characteristic, the sintering temperature is moderate, preparation technology is simple and is easy to control, and cost is low.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

A kind of high dielectric low temperature co-fired ceramic dielectric material and preparation method thereof

The invention discloses a high dielectric low temperature co-fired ceramic dielectric material and a preparation method thereof, the material comprises the following raw materials by mass: 5-20% of glass powder and 80-95% of K2Sr4Nb6O20-0.2Sc2O3. The glass powder includes the following raw materials by mass: 15-30% of Na2CO3, 5-20% of SiO2, 10-25% of KF, and 25-40% of H3BO3. The preparation methodis as follows: weighing the raw materials according to the stoichiometric ratio of the general formula K2Sr4Nb6O20-0.2Sc2O3 to obtain a frit A; mixing the glass powder B and the 80% of 95% of the frit A according to the mass percentage for ball milling, adding an adhesive, granulating, thermally incubating at 900 DEG C -950 DEG C for 1 hour, and cooling. The high dielectric low temperature co-fired ceramic dielectric material has a low sintering temperature, a high dielectric constant and a low dielectric loss, and can be co-fired with a high conductivity silver metal internal electrode.

Owner:TAIYUAN UNIV OF TECH

A kind of negative temperature coefficient ceramic dielectric material and preparation method thereof

The invention belongs to the technical field of ceramic dielectric materials, and provides a negative temperature coefficient ceramic dielectric material and a preparation method thereof in order to prevent the capacitor from increasing in capacitance due to temperature rise or other factors during use and to improve reliability. 10‑30% by weight of CaTiO 3 and 70‑90% by weight of K 2 Sr 4 (Nb 8 Mg 2 )O 27 composition. Conforms to EIA X7R standard, and the capacitance change rate within the temperature range of -55°C to 125°C does not exceed ±15%. It has good dielectric properties, the dielectric constant can reach about 4700 at 25°C, and the loss is 0.0065. It has a negative capacitance temperature coefficient, which can compensate for the increase in capacitance caused by temperature rise or other factors, and improve reliability. The sintering temperature range is wide, the performance is adjustable, the stability and reproducibility are good, and the reliability is high. It does not contain harmful substances such as heavy metals, and is environmentally friendly.

Owner:TAIYUAN NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com