A temperature-stable ceramic dielectric material and its preparation method

A temperature-stable, ceramic dielectric technology, used in ceramics, inorganic insulators, etc., can solve the problems of narrow operating temperature range, high sintering temperature, low dielectric constant, etc., and achieve a wide operating temperature range, high dielectric constant, high The effect of dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] A method for preparing a temperature-stable ceramic dielectric material, comprising the following steps:

[0023] (1) the raw material Bi 2 o 3 , MgO and TiO 2 According to the general formula BiMg 0.1 Ti 0.7 o 3 , carry out batching ball milling, heat up to 800 ° C, keep warm for 2-4 hours, and obtain frit A;

[0024] (2) According to the mass percentage, 5-20% KNbO 3 , 10-20% SrTiO 3 Carry out secondary batching with 70-85% frit A to obtain batching B;

[0025] (3) Ball mill ingredient B, add 5-8wt% binder of ingredient B to granulate, press into a green body, raise the temperature to 400-500°C, then raise the temperature to 1020°C-1050°C for 1 hour, and cool it to obtain Temperature stable ceramic dielectric material.

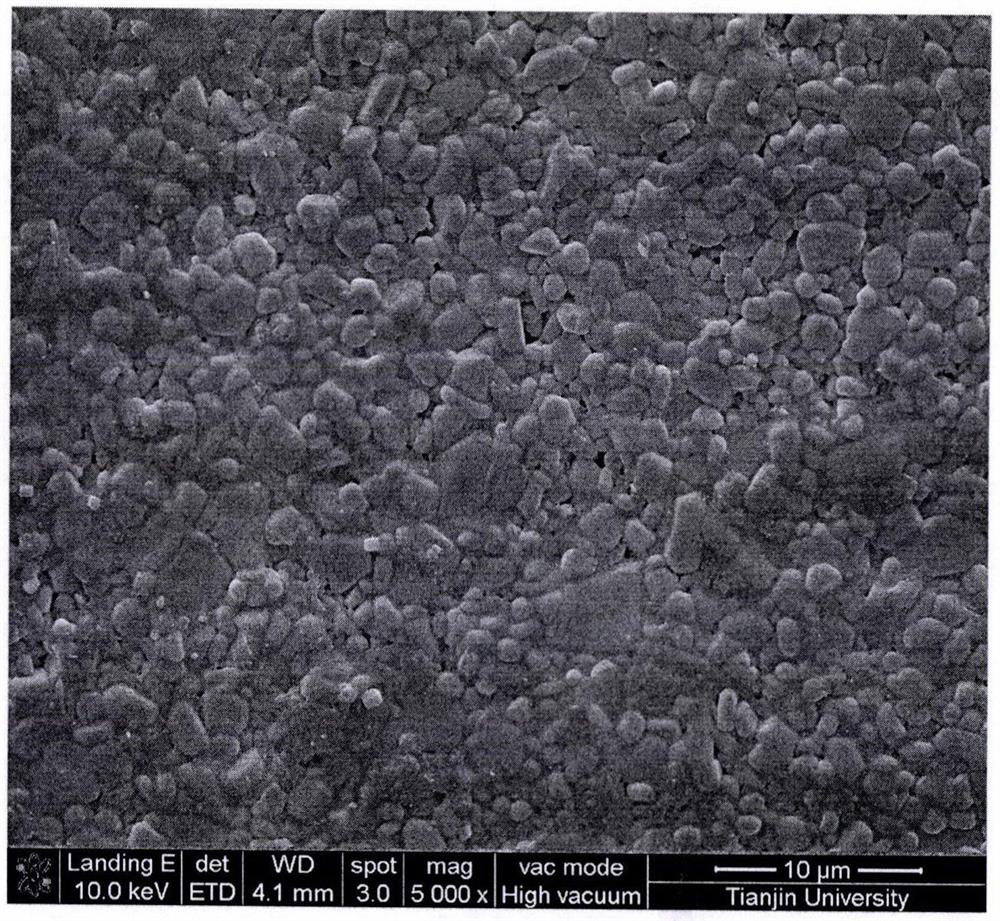

[0026] In the present invention, the binder added in step (3) will volatilize in the subsequent heating process, and the sintering process in step (3) of the present invention is mainly for the purpose of making the ceramic dielectric materia...

Embodiment 1

[0043] Raw material Bi 2 o 3 , MgO and TiO 2 According to the general formula BiMg 0.1 Ti 0.7 o 3 , for batching, ball milling on a ball mill with a rotating speed of 400r / min for 6 hours, drying in a 3.3kw ordinary oven at 100°C, and passing through 250 holes / cm 2 Sieve the sample, raise the temperature to 800°C at 5°C / min, and keep the temperature at 800°C for 3 hours to obtain frit A.

[0044] For secondary batching, according to 5% KNbO 3 , 10% SrTiO 3 Mix evenly with 85% of the mass of frit A, add deionized water, mill on a ball mill at a speed of 400r / min for 8 hours, dry at 120°C, pass through 250 holes / cm 2 Sieve the sample, add 8wt% paraffin to granulate, press into a green body, first heat up to 450°C at a heating rate of 2°C / min, then heat to 1020°C at a heating rate of 10°C / min for firing, and hold for 1 hour. After cooling, a ceramic dielectric material is obtained.

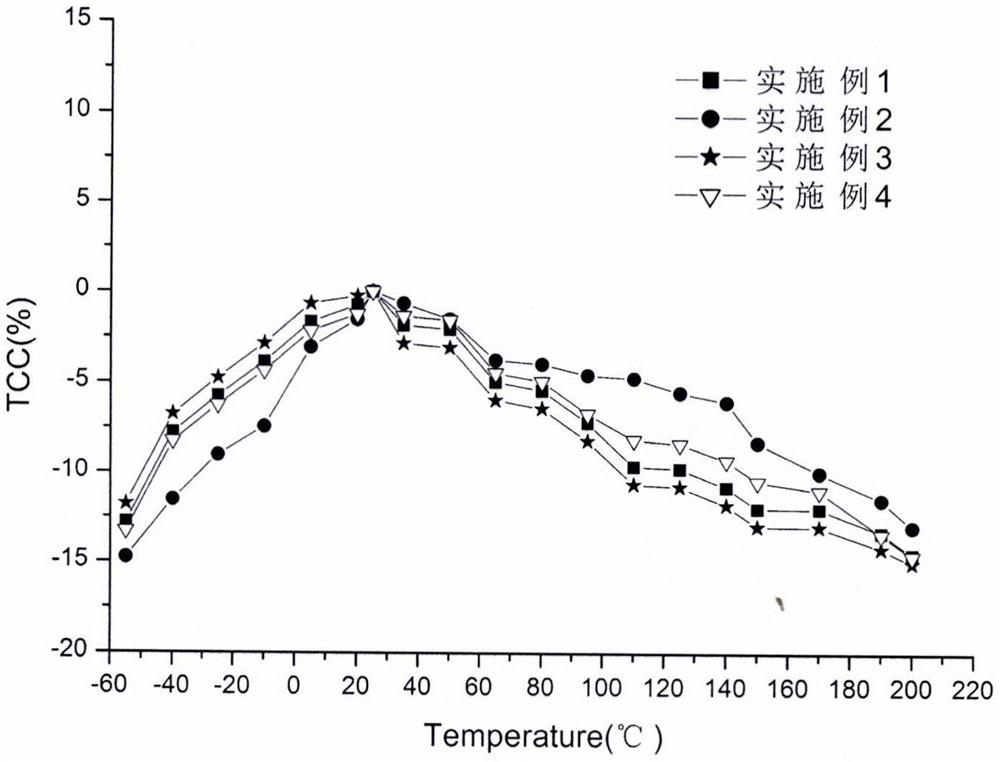

[0045] The test result (test frequency is 1KHz) of the dielectric property of above-ment...

Embodiment 2

[0049] Raw material Bi 2 o 3 , MgO and TiO 2 According to the general formula BiMg 0.1 Ti 0.7 o 3 , for batching, ball milling on a ball mill with a rotating speed of 400r / min for 6 hours, drying in a 3.3kw ordinary oven at 100°C, and passing through 250 holes / cm 2 Sieve the sample, raise the temperature to 800°C at 5°C / min, and keep the temperature at 800°C for 3 hours to obtain frit A.

[0050] For secondary batching, according to 10% KNbO 3 , 20% SrTiO 3 Mix evenly with 70% of the mass relationship of frit A, add deionized water, ball mill on a ball mill at a speed of 400r / min for 8 hours, dry at 120°C, pass through 250 holes / cm 2 Sieve the sample, add 8wt% paraffin to granulate, press into a green body, first heat to 450°C at a heating rate of 2°C / min, and then heat to 1030°C at a heating rate of 10°C / min for firing, and hold for 1 hour. After cooling, a ceramic dielectric material is obtained.

[0051] The test result (test frequency is 1KHz) of above-mentioned e...

PUM

| Property | Measurement | Unit |

|---|---|---|

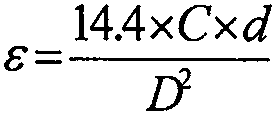

| diameter | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com