A kind of high dielectric low temperature co-fired ceramic dielectric material and preparation method thereof

A technology of low temperature co-fired ceramics and dielectric materials, applied in the field of ceramic dielectric materials, can solve the problems of high sintering temperature, low dielectric constant and high loss, and achieve high dielectric constant, high dielectric constant and low dielectric loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

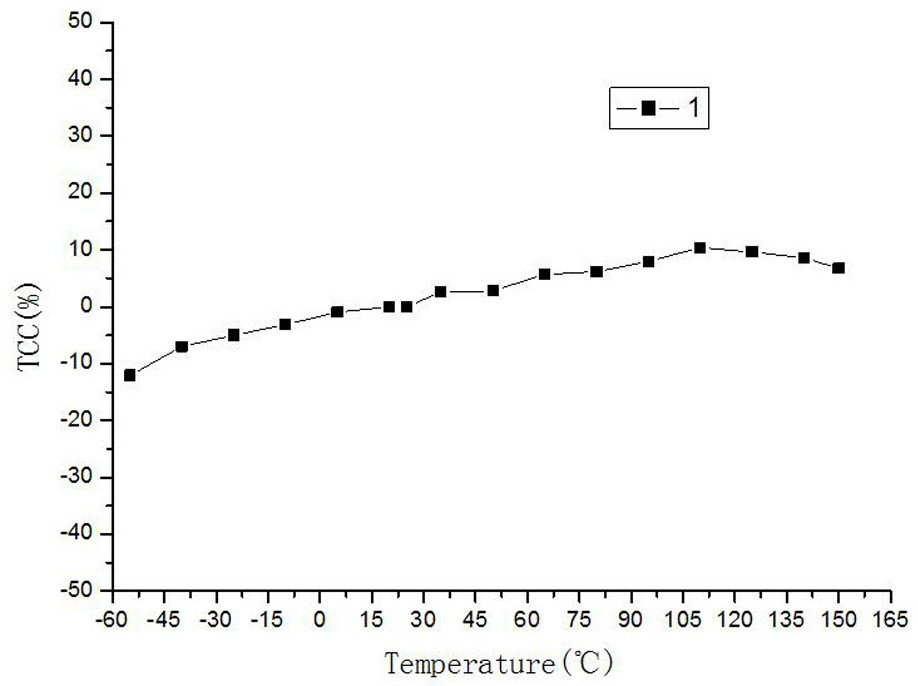

Image

Examples

Embodiment 1

[0028] A high-dielectric low-temperature co-fired ceramic dielectric material, comprising the following raw materials in mass percentages: glass powder 5%, K 2 Sr 4 Nb 6 o 20 -0.2Sc 2 o 3 95%, the glass powder includes the following raw materials in mass percentage: Na 2 CO 3 15%, SiO 2 20%, KF 25% and H 3 BO 3 40%.

[0029] Its preparation process is as follows:

[0030] 1) The raw material K 2 CO 3 , SrCO 3 , Nb 2 o 5 and Sc 2 o 3 According to formula K 2 Sr 4 Nb 6 o 20 -0.2Sc 2 o 3 , for batching, ball milling on a ball mill with a speed of 400r / min for 6 hours, in a 3.3kw ordinary oven, after drying at 100°C, pass through 250 holes / cm 2 Sieve the sample, raise the temperature to 1100°C at a rate of 5°C / min, and keep it at 1100°C for 3 hours to obtain frit A.

[0031] 2) Weigh Na 2 CO 315g, SiO 2 20g, KF 25g, H 3 BO 3 40g, mixed, cooled with molten water, ground, and sieved to obtain glass powder B.

[0032] 3) Carry out secondary batching, wei...

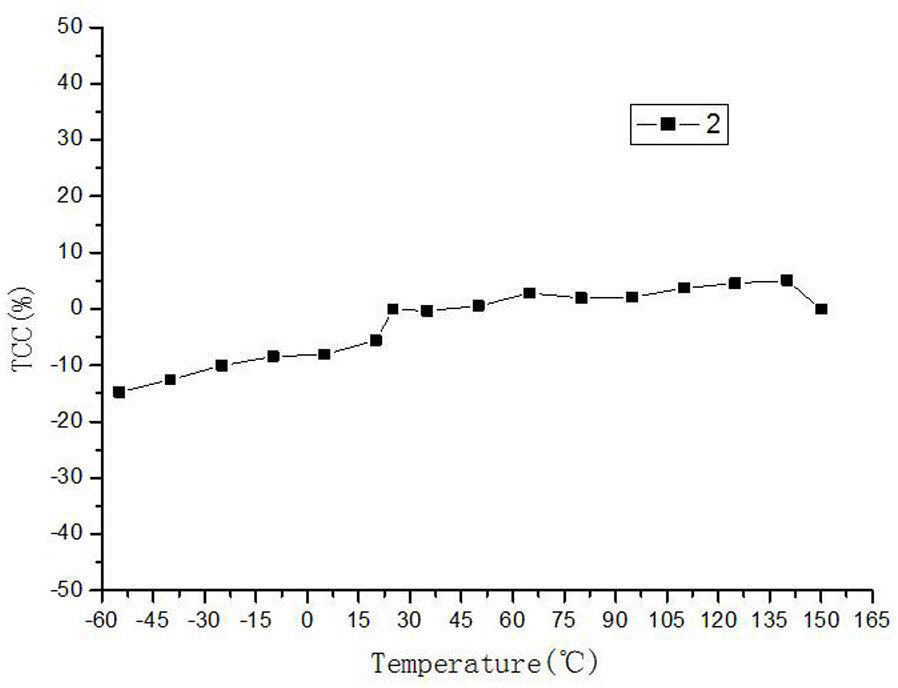

Embodiment 2

[0037] A high-dielectric low-temperature co-fired ceramic dielectric material, including the following raw materials in mass percentages: glass powder 10%, K 2 Sr 4 Nb 6 o 20 -0.2Sc 2 o 3 90%. Described glass powder comprises the raw material of following mass percent: Na 2 CO 3 25%, SiO 2 15%, KF 20% and H 3 BO 3 40%.

[0038] The preparation process is as follows:

[0039] 1) The raw material K 2 CO 3 , SrCO 3 , Nb 2 o 5 and Sc 2 o 3 According to formula K 2 Sr 4 Nb 6 o 20 -0.2Sc 2 o 3 , for batching, ball milling on a ball mill with a rotating speed of 400r / min for 6 hours, drying in a 3.3kw ordinary oven at 100°C, and passing through 250 holes / cm 2 Sieve the sample, raise the temperature to 1100°C at 10°C / min, and keep it at 1100°C for 2 hours to obtain frit A.

[0040] 2) Weigh Na 2 CO 3 25g, SiO 2 15g, KF 20g, H 3 BO 3 40g, mixed, cooled with molten water, ground, and sieved to obtain glass powder B.

[0041] 3) For secondary batching, weig...

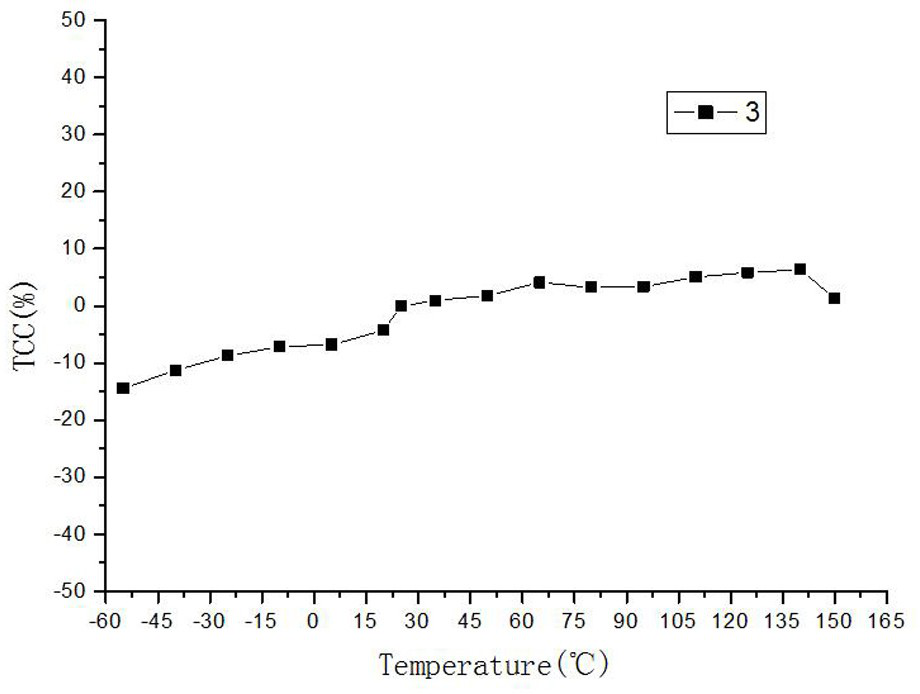

Embodiment 3

[0046] A high-dielectric low-temperature co-fired ceramic dielectric material, comprising the following raw materials in mass percentages: glass powder 15%, K 2 Sr 4 Nb 6 o 20 -0.2Sc 2 o 3 85%. Described glass powder comprises the raw material of following mass percent: Na 2 CO 3 30%, SiO 2 20%, KF 25% and H 3 BO 3 25%.

[0047] The preparation process is as follows:

[0048] 1) The raw material K 2 CO 3 , SrCO 3 , Nb 2 o 5 and Sc 2 o 3 According to formula K 2 Sr 4 Nb 6 o 20 -0.2Sc 2 o 3 , for batching, ball milling on a ball mill with a speed of 400r / min for 6 hours, drying at 100°C in a 3.3kw ordinary oven, and passing through 120 holes / cm 2 Sieve the sample, raise the temperature to 1000°C at 8°C / min, and keep it at 1000°C for 4 hours to obtain frit A.

[0049] 2) Weigh Na 2 CO 3 30g, SiO 2 20g, KF 25g, H 3 BO 3 25g, mixed, cooled with molten water, ground, and sieved to obtain glass powder B.

[0050] 3) Carry out secondary batching, weigh f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com