Machineable ceramic material and preparation method thereof

A technology of ceramic materials and mass percentage, which is applied in the field of medical materials, can solve the problems of high sintering temperature, low strength and toughness, and achieve the effects of low energy consumption, short production cycle, performance enhancement and toughening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] According to the proportions in Table 1 below, ball mill on a ball mill with a rotation speed of 400r / min for 6 hours, dry at 100°C in a 3.3kw ordinary oven, and pass through 250 holes / cm 2 Sieve the sample, raise the temperature to 1100°C at 5°C / min, and keep it at 1100°C for 2 hours, cool it with molten water, grind, and sieve to obtain glass powder.

[0032] Table 1

[0033]

[0034] For secondary batching, according to 90% glass powder, 5% nano diatomite and 5% ZrO 2 Mix evenly, add deionized water, mill on a ball mill at a speed of 400r / min for 8 hours, dry at 120°C, pass through 250 holes / cm 2 Separating sieve, adding 8wt% paraffin wax to granulate, pressing into green body, first heating to 450°C at a heating rate of 2°C / min, and then heating to 1000°C at a heating rate of 10°C / min for firing, holding for 1 hour, After cooling a ceramic medium is produced.

[0035] The test results of the mechanical properties of the above examples are shown in Table 2 below....

Embodiment 2

[0039] According to the ratio of ingredients in Table 3 below, ball mill on a ball mill with a rotation speed of 400r / min for 4 hours, dry at 100°C in a 3.3kw ordinary oven, and pass through 250 holes / cm 2 Sieve the sample, raise the temperature to 1100°C at 7°C / min, and keep it at 1100°C for 2 hours, cool it with molten water, grind, and sieve to obtain glass powder.

[0040] table 3

[0041]

[0042] For secondary batching, according to 85% glass powder, 10% nano diatomite and 5% ZrO 2 Mix evenly, add deionized water, mill on a ball mill at a speed of 400r / min for 8 hours, dry at 120°C, pass through 250 holes / cm 2 Sieve the sample, add 8wt% paraffin to granulate, press into a green body, first heat to 450°C at a heating rate of 2°C / min, and then heat to 1010°C at a heating rate of 10°C / min for firing, and hold for 1 hour. After cooling a ceramic medium is produced.

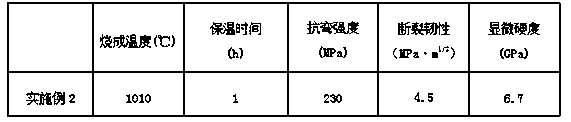

[0043] The test results of the mechanical properties of the above examples are detailed in Table 4 belo...

Embodiment 3

[0047] According to the proportions in Table 5 below, mill on a ball mill with a rotation speed of 400r / min for 4 hours, dry at 100°C in a 3.3kw ordinary oven, and pass through 250 holes / cm 2 Sieve the sample, raise the temperature to 1100°C at 7°C / min, and keep it at 1100°C for 3 hours, cool with molten water, grind, and sieve to obtain glass powder.

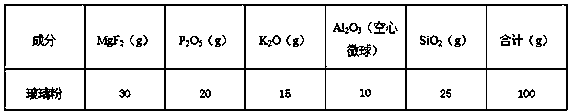

[0048] table 5

[0049]

[0050] For secondary batching, according to 80% glass powder, 15% nano diatomite and 5% ZrO 2 Mix evenly, add deionized water, mill on a ball mill at a speed of 400r / min for 8 hours, dry at 120°C, pass through 250 holes / cm 2 Sieve the sample, add 8wt% paraffin to granulate, press into a green body, first heat up to 450°C at a heating rate of 2°C / min, then heat to 1020°C at a heating rate of 10°C / min for firing, and hold for 1 hour. After cooling a ceramic medium is produced.

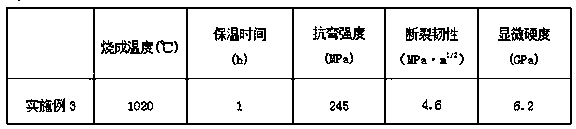

[0051] The test results of the mechanical properties of the above examples are detailed in Table 6 below.

[0052] Table...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com