Low-temperature co-fired ceramic dielectric material and preparation method thereof

A technology of low-temperature co-fired ceramics and dielectric materials, which is applied in the field of substrate materials for communication components, can solve the problems of high sintering temperature, low bending strength, and low thermal conductivity, and achieve high thermal conductivity, low dielectric constant, high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail in combination with the embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention. The technical solutions of the present invention will be described in detail below in conjunction with the examples, but the scope of protection is not limited thereto.

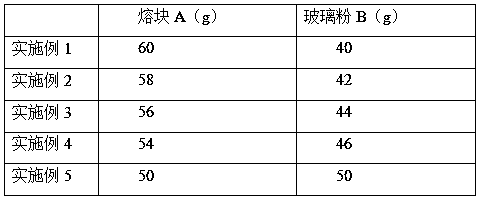

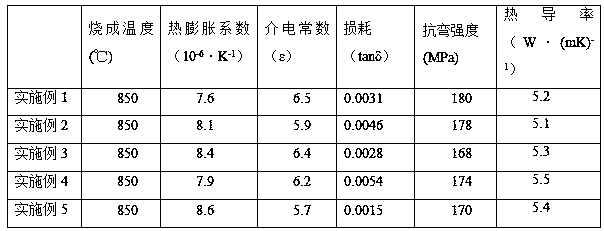

[0026] The first set of examples

[0027] Raw material Al 2 o 3 , Nb 2 o 5 and ZnO according to the general formula xAl 2 o 3 -2Nb 2 o 5 -ZnO, where x=4, batching, ball milling on a ball mill with a rotating speed of 400r / min for 6 hours, drying in a 3.3kw ordinary oven at 100°C, passing through 250 holes / cm 2 Sieve the sample, raise the temperature to 1050°C at 7°C / min, and keep the temperature at 1050°C for 3 hours to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com