High-power warm-white light solid illumination SiAlON fluorescent transparent ceramic and preparation method thereof

A solid-state lighting, transparent ceramic technology, applied in energy-saving lighting, chemical instruments and methods, luminescent materials, etc., can solve the problem that it is difficult to ensure the elimination of glass phase, the density is only 90%, the reduction of glass is equal, and the repeatability is achieved. Strong, excellent mechanical properties, good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

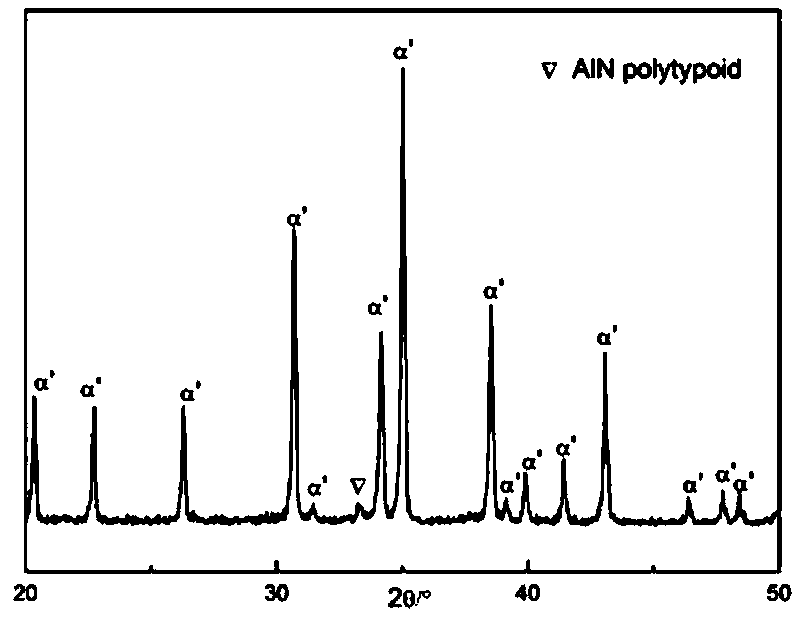

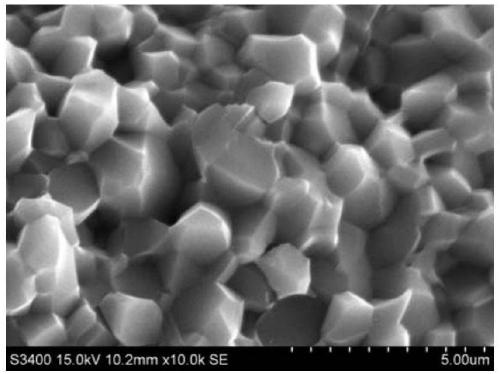

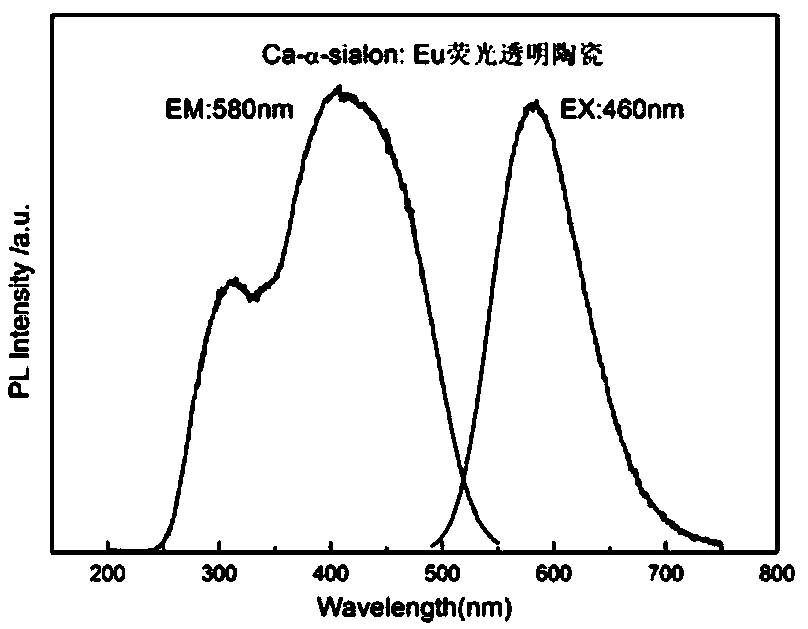

[0031] α-Si with an oxygen content of 1.5wt% 3 N 4 , AlN with an oxygen content of 1.0 wt%, α-Al 2 o 3 , CaCO 3 and Eu 2 o 3 as raw material, according to Ca m / 2-x-yv / 2 Si 12-m-n Al m+n o n N 16-n :xEu 2+ ,y M v+ The stoichiometric ratio of (m=0.8, n=1.0, x=0.02, y=0) selects the above-mentioned raw materials with a total weight of 50 g, mixes them, and adds 2.5 g of AlN to the mixture, and puts the above-mentioned raw materials in a plastic bottle mixed with Si 3 N 4 The ball is the ball milling medium, the mass ratio of the ball to the material is 4:1, add 400ml of absolute ethanol, and roll the ball mill for 24 hours to obtain the slurry; the slurry is evaporated to dryness in a rotary evaporator at 60°C, and then put into a vacuum drying oven to vacuum Dry for at least 24 hours, then take it out, grind for 20 minutes, and pass through a 100-mesh sieve to obtain the undersize; put the sieved undersize into a graphite mold with a diameter of 48 mm, then put it ...

Embodiment 2

[0036] α-Si with an oxygen content of 1.5wt% 3 N 4 , AlN with an oxygen content of 1.0 wt%, α-Al 2 o 3 , CaCO 3 、Eu 2 o 3 and Y 2 o 3 as raw material, according to Ca m / 2-x-yv / 2 Si 12-m-n Al m+n o n N 16-n :xEu 2+ ,y M v+The stoichiometric ratio of (m=0.8, n=1.0, x=0.02, y=0.05) selects the above-mentioned raw materials with a total weight of 50 g, and additionally adds 20 g of AlN to the mixture, mixes the above-mentioned raw materials in a plastic bottle, and Si 3 N 4 The ball is the ball milling medium, the ball-to-material ratio is 4:1, add 400ml of absolute ethanol, and roll the ball mill for 24 hours to obtain the slurry; the slurry is evaporated to dryness in a rotary evaporator at 60°C, and then placed in a vacuum drying oven for vacuum drying At least 24 hours, then take it out, grind for 20min, and pass through a 100-mesh sieve to obtain the undersize; put the sieved undersize into a graphite mold with a diameter of 48mm, and then put it into a hot-pr...

Embodiment 3

[0039] α-Si with an oxygen content of 1.5wt% 3 N 4 , AlN with an oxygen content of 1.0 wt%, α-Al 2 o 3 , CaCO 3 、Eu 2 o 3 and Sc 2 o 3 as raw material, according to Ca m / 2-x-yv / 2 Si 12-m-n al m+n o n N 16 -n:xEu 2+ ,yM v+ The stoichiometric ratio of (m=1.6, n=2.0, x=0.04, y=0.03) is selected as a total weight of 50 g of the above raw materials, and an additional 16 g of Si is added to the mixture 3 N 4 and 4gAlN complex, mix the above raw materials in a plastic bottle, and use Si 3 N 4 The ball is the ball milling medium, the ball-to-material ratio is 4:1, add 400ml of absolute ethanol, and roll the ball mill for 24 hours to obtain the slurry; the slurry is evaporated to dryness in a rotary evaporator at 60°C, and then placed in a vacuum drying oven for vacuum drying At least 24 hours, then take it out, grind for 20min, and pass through a 100-mesh sieve to obtain the undersize; put the sieved undersize into a graphite mold with a diameter of 48mm, and then put...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com