Sodium bismuth phthalate-barium zirconium phthalate leadless piezoelectric ceramic and its preparation method

A technology of barium zirconate titanate and sodium bismuth titanate, applied in piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., to achieve the effects of reducing leakage current, easy polarization, and good piezoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

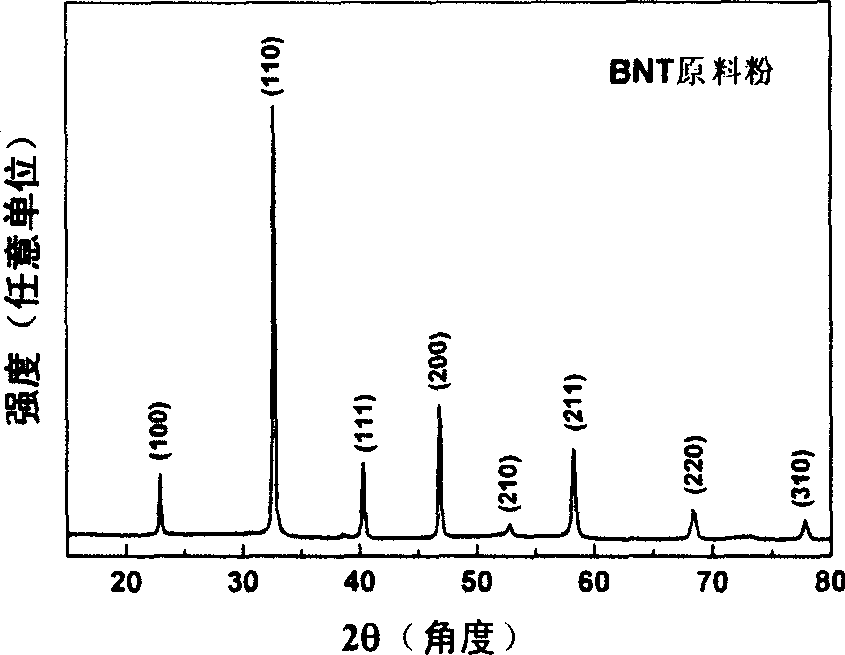

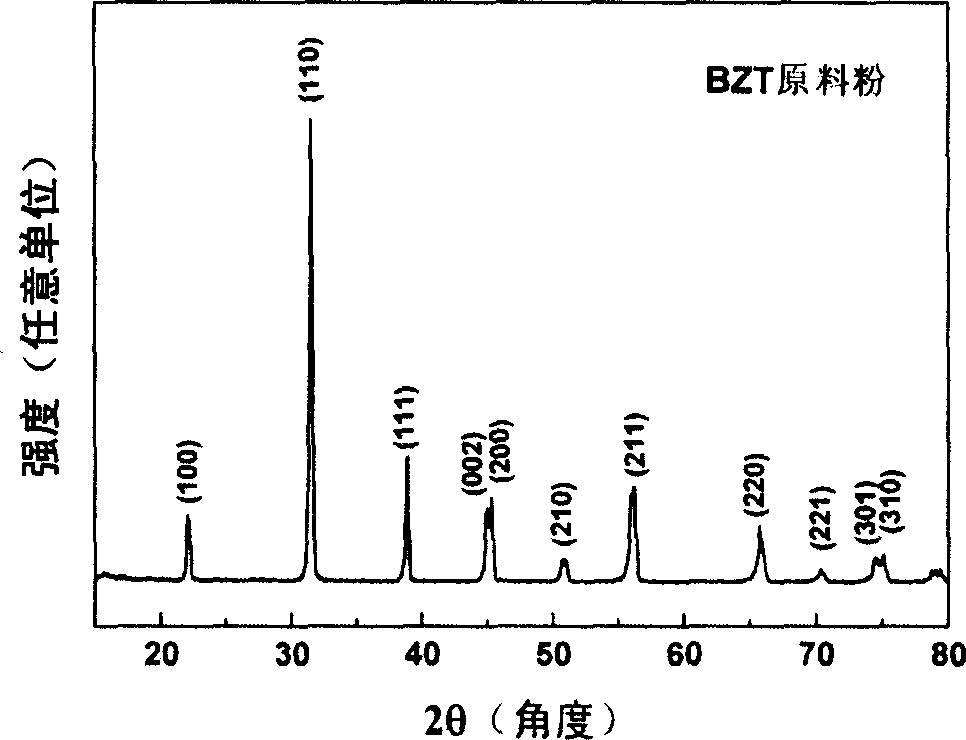

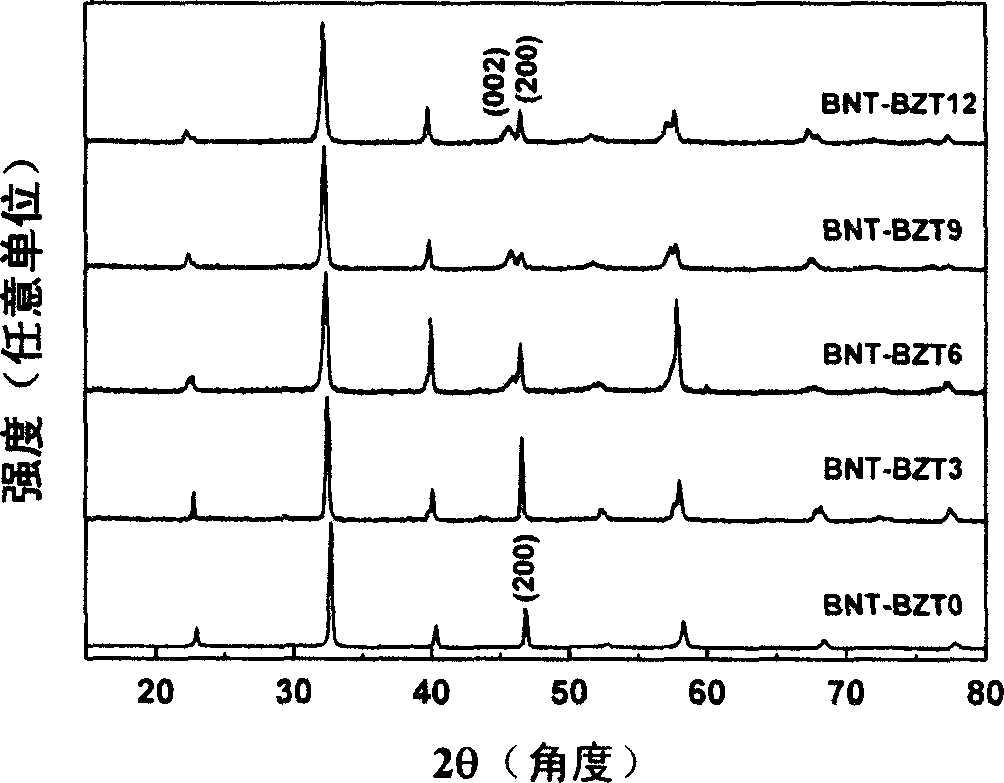

[0024] The following examples are given to illustrate the present invention in detail. Example: with Bi 2 o 3 、Na 2 CO 3 、TiO 2 As raw material, according to the chemical formula (Bi 0.5 Na 0.5 )TiO 3 Dosing; with BaCO 3 , ZrO 2 、TiO 2 As a raw material, according to the chemical formula Ba(Ti 0.942 Zr 0.058 )O 3 Proceed to the ingredients. Use absolute ethanol as the medium for wet grinding respectively, dry the dry powder after wet grinding for 2-3 hours. BNT raw material powder was pre-fired at 850°C for 3 hours in air, ground and sieved (200 mesh) to obtain BNT raw material powder with a composite perovskite phase; BZT raw material powder was pre-sintered at 1200°C for 3 hours in air, ground After sieving (200 meshes), the BZT raw material powder having a perovskite phase was obtained. With pre-burned BNT, BZT powder as raw material powder, according to the chemical formula (Bi 0.5 Na 0.5 )TiO 3-x Ba(Ti 0.942 Zr 0.058 )O 3 [BNT-BZT100x] (x=0.00, 0.03, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com