Constant pressure hydro-thermal preparation method for barium zirconate titanate powder

A barium zirconate titanate and atmospheric pressure hydrothermal technology is applied in the field of preparation of barium zirconate titanate powder, which can solve the problems of high performance requirements of reaction equipment, high energy consumption in the reaction process, uneven particle size distribution, etc., and achieves low cost , reaction conditions in real time, easy to adjust and control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: prepare BaTi 0.8 Zr 0.2 o 3 . Use a measuring cylinder to measure 0.2 liters of 4.0mol / L titanium tetrachloride solution, 0.2 liters of 1.0mol / L zirconium oxychloride solution and 1 liter of 1.2 mol / L barium chloride solution in the container, and add 0.6 liters of deionized water to stir to mix evenly; then pour the above mixed solution into the normal pressure reactor, start stirring, and add 312g of sodium hydroxide solid to it, heat up to 80°C with an electric heating mantle and keep the temperature for 6 hours, cool to room temperature, and then use Rinse with deionized water; the above washing process is carried out in a fully enclosed state. After washing until the conductivity is less than 50us / cm, it is qualified when the element ratio of Ba / (Ti+Zr) is between 0.995-1.005 through XRF detection. , dried and pulverized after passing the test to obtain barium zirconate titanate powder.

Embodiment 2

[0023] Embodiment 2: prepare BaTi 0.82 Zr 0.18 o 3 Use a graduated cylinder to measure 0.328 liters of 2.5mol / L titanium tetrachloride solution, 0.06 liters of 3.0mol / L zirconium oxychloride and 1.5 liters of 0.8mol / L barium chloride solution in the container, and add 3.11 liters of deionized water to stir until the mixture is uniform; then pour the above mixed solution into the normal pressure reaction kettle, start stirring, and add 460g of sodium hydroxide solid to it, heat up to 100°C with an electric heating mantle and keep the temperature for 2 hours, cool to room temperature, and then use Rinse with deionized water. The above washing process is carried out in a fully enclosed state. After washing until the conductivity is less than 50us / cm, send it to XRF for inspection. When the Ba / (Ti+Zr) element ratio is between 0.995-1.005, it is qualified , dried and pulverized after passing the test to obtain barium zirconate titanate powder.

Embodiment 3

[0024] Embodiment 3: prepare BaTi 0.82 Zr 0.18 o 3 ; Measure 0.16 liters of 5.0mol / L titanium tetrachloride solution, 0.1 liters of 2.0mol / L zirconium oxychloride and 1 liter of 1.1mol / L barium chloride solution in a container, and add 0.41 liters of deionized water Stir until evenly mixed; then pour the above mixed solution into a normal-pressure reactor, start stirring, and add 325g of sodium hydroxide solid to it, heat up to 90°C with an electric heating mantle and keep the temperature for 4 hours, then cool to room temperature, and then Rinse with deionized water. The above washing process is carried out in a fully enclosed state. After washing until the conductivity is less than 50us / cm, send it to XRF for inspection. When the element ratio of Ba / (Ti+Zr) is between 0.995-1.005, the If it is qualified, it is dried and pulverized to obtain barium zirconate titanate powder.

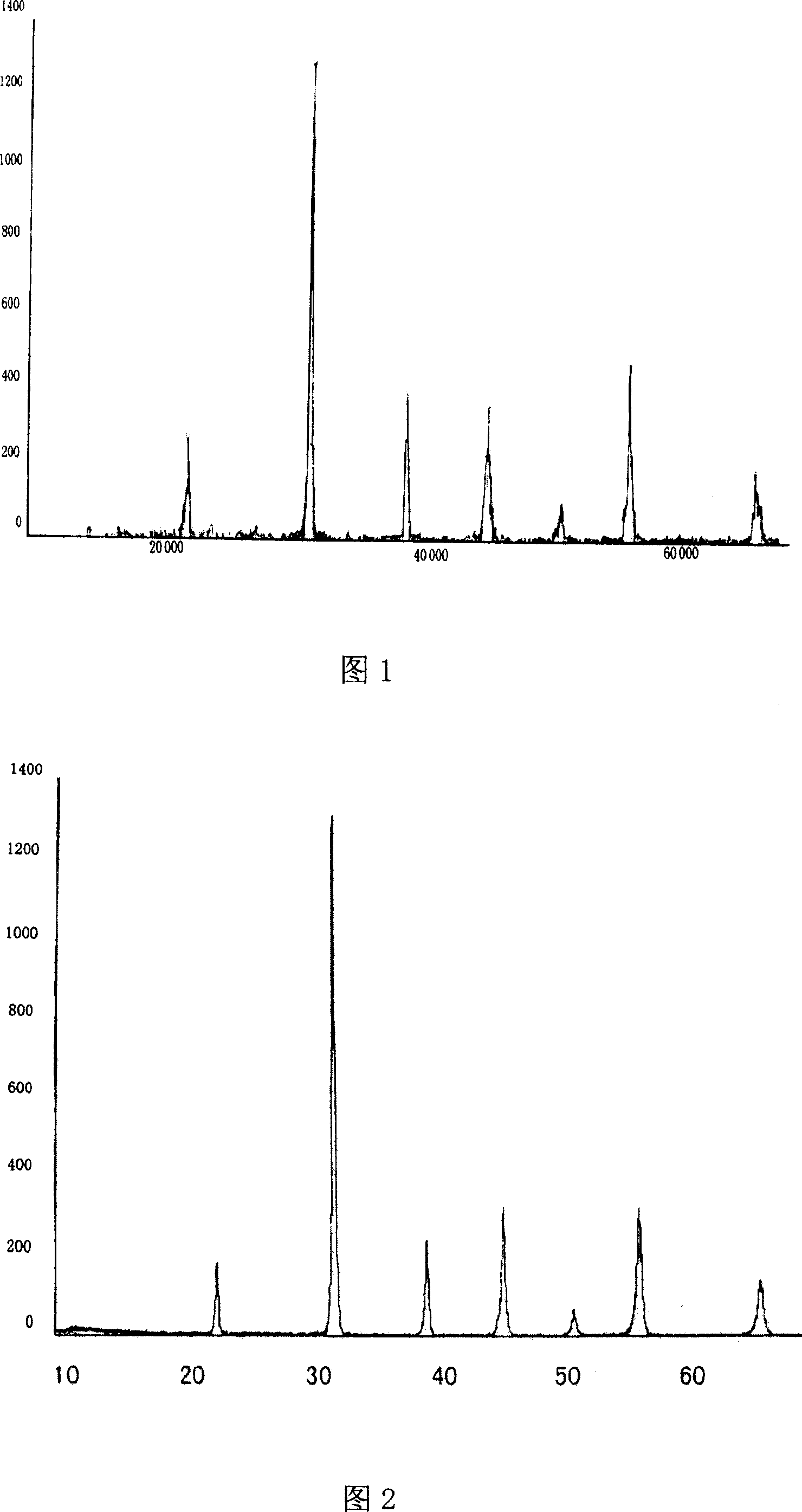

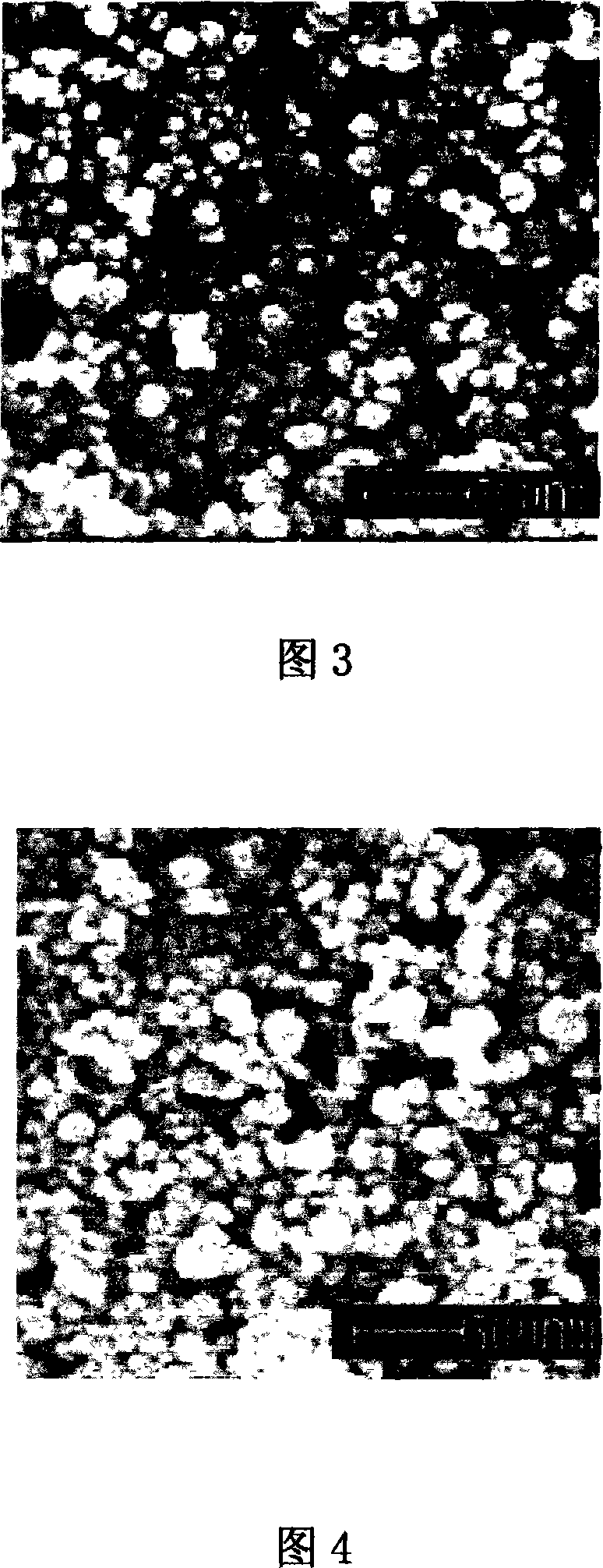

[0025] Analysis of the barium zirconate titanate dry powders in the above-mentioned examples 1 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com