Method for preparing barium zirconate crucible by slip casting

A technology of grouting molding and barium zirconate, which is applied in the field of high-temperature solid electrolyte materials, can solve the problems of difficult sintering of high-purity and high-density barium zirconate crucibles, and achieve the effect of cheap raw materials, low cost and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Weigh 500 grams of barium zirconate powder calcined at 1600°C for 8 hours, add 30wt% deionized water, ball mill for 24 hours, and then dry in an oven at 80°C. Add 15wt% deionized water and 10wt% gum arabic solution to the dried powder, mix and ball mill for 2 hours, and pass through a 200-mesh sieve to remove large particles of impurities that may be contained in the slurry to obtain a pouring slurry. Then add the slurry in a plaster mold of a certain shape, and after the thickness reaches 2mm, pour out the remaining slurry. Place the gypsum mold for a period of time, then remove the mold, pour out the green body, dry it in an oven at 30°C, trim the green body after reaching a certain level, and finally dry it naturally at room temperature. Place the formed dry biscuit sample in a muffle furnace, raise the temperature to 1640°C at a rate of 2°C / min in an air atmosphere, and keep it warm for 10 hours to obtain a barium zirconate crucible.

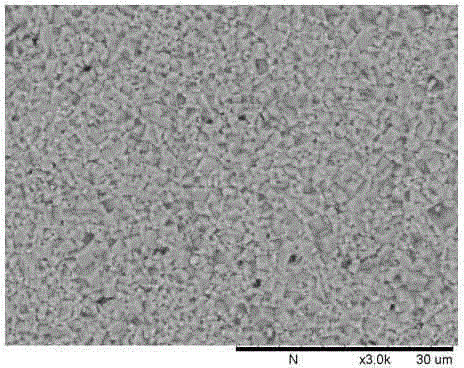

[0023] figure 1 is the fract...

Embodiment 2

[0025] Weigh 500 g of barium zirconate powder calcined at 1600 °C for 10 h, add 30 wt % deionized water, ball mill for 24 hours, and then dry in an oven at 80 °C. Add 15wt% deionized water and 10wt% gum arabic solution to the dried powder, mix and ball mill for 5 hours, and pass through a 200-mesh sieve to remove large particles of impurities that may be contained in the slurry to obtain a pouring slurry. Then add the slurry in a plaster mold of a certain shape, and after the thickness reaches 10mm, pour out the remaining slurry. Place the gypsum mold for a period of time, then remove the mold, pour out the green body, dry it in an oven at 30°C, trim the green body after reaching a certain level, and finally dry it naturally at room temperature. Place the formed dry green body sample in a muffle furnace, raise the temperature to 1750°C at a rate of 2°C / min in an air atmosphere, and keep it warm for 10 hours to obtain a barium zirconate crucible.

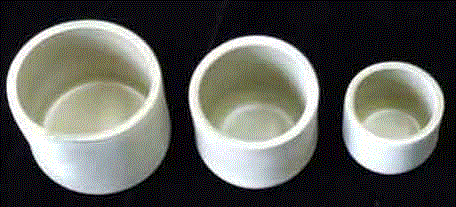

[0026] figure 2 Barium zir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com