Barium zirconate titanate calcium-based piezoelectric ceramic and preparation method thereof

A technology of barium calcium zirconate titanate and electric ceramics, which is applied in the field of piezoelectric ceramic electronic components, can solve the problems of high investment in precision equipment, complex processes, and large fluctuations in electrical properties of ceramic materials, and achieve high densification and electrical performance. The effects of excellent performance, considerable application value and commercial prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

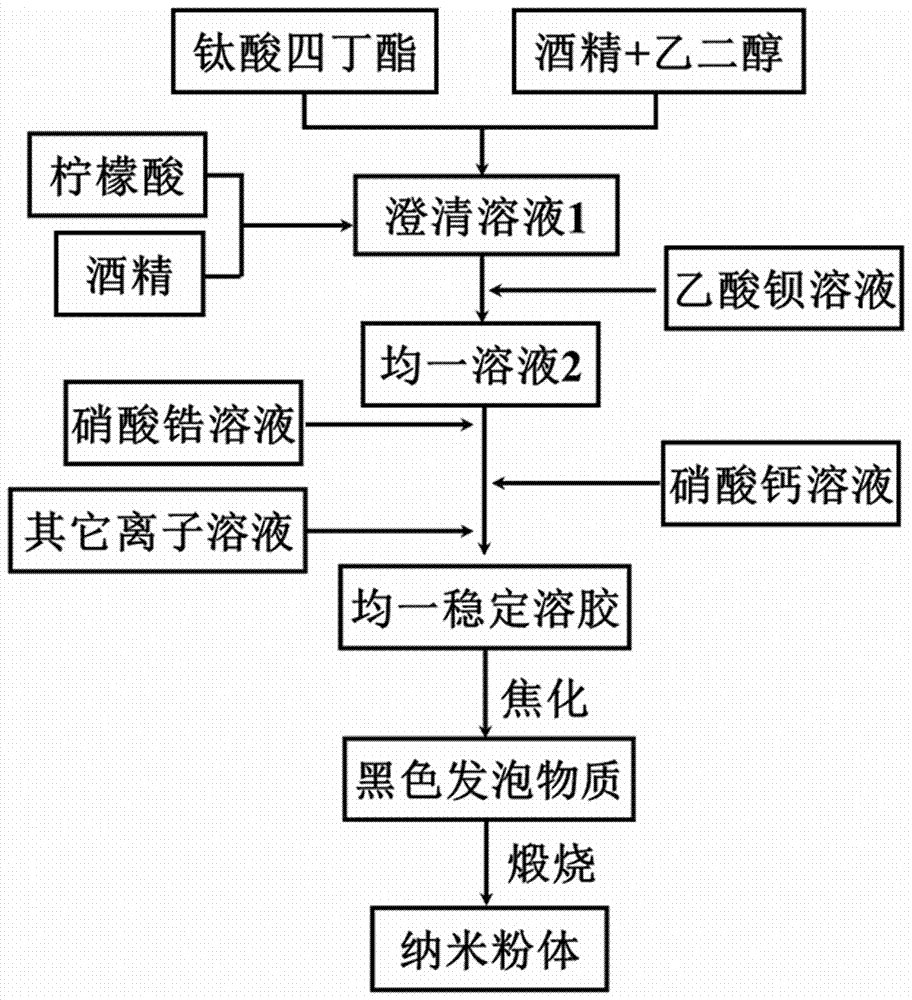

[0031] Such as figure 1 As shown, the preparation method of the barium calcium zirconate titanate-based piezoelectric ceramics comprises the following steps:

[0032] 1) Dissolve tetrabutyl titanate in ethylene glycol and alcohol, then add the mixed solution of citric acid and alcohol to the above solution dropwise, and stir at room temperature for 0.5-1 hour to obtain clear solution 1;

[0033] 2) Dissolve barium acetate weighed according to the molar ratio of metal ions in the chemical formula in deionized water, and then add it dropwise to the clear solution 1 prepared in step 1) at a temperature of 50~65°C, and stir for 0.5~1 hour Prepare a homogeneous solution 2;

[0034] 3) Dissolve zirconium nitrate and calcium nitrate weighed according to the molar ratio of metal ions in the chemical formula respectively in deionized water, and add dropwise to the homogeneous solution prepared in step 2) in the order of first adding zirconium nitrate and then adding calcium nitrate ...

Embodiment 1

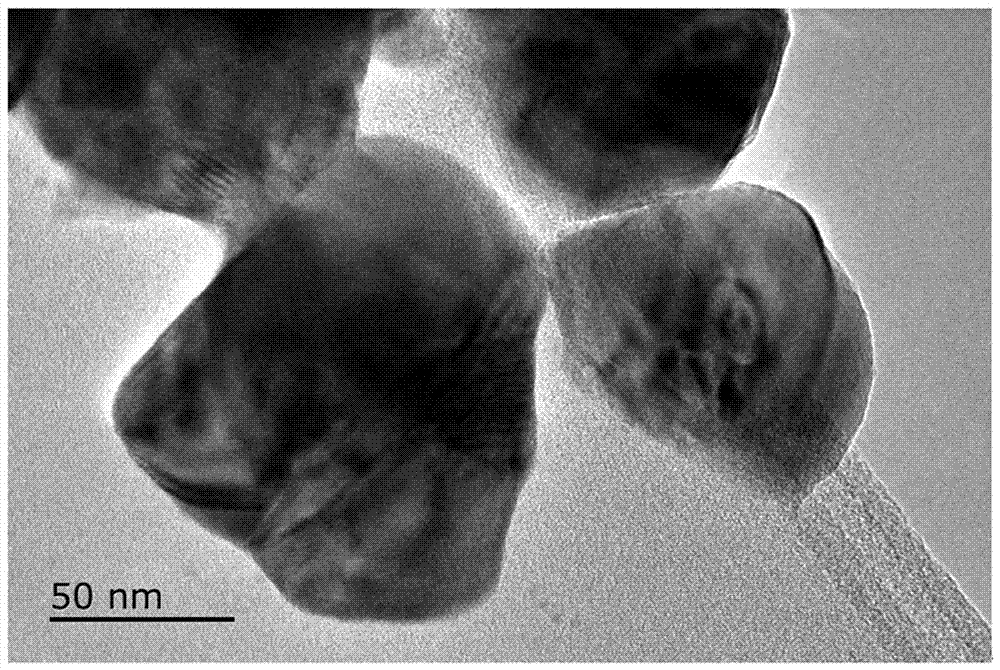

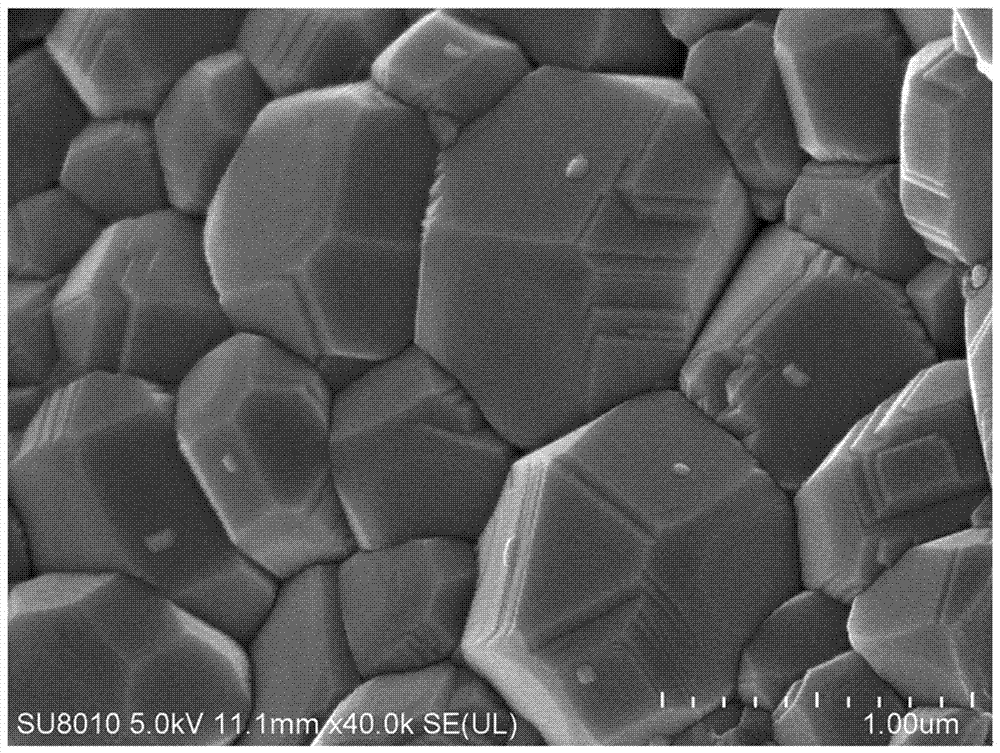

[0042] Preparation of Ba 0.85 Ca 0.15 Ti 0.90 Zr 0.10 o 3 Ceramics: Dissolve 3.0632g of tetrabutyl titanate in a mixed solution of 7.5ml of alcohol and 12ml of ethylene glycol, and stir thoroughly at room temperature for 1 hour; add the mixed solution of 6.3042g of citric acid and 2.7642g of alcohol to the above solution dropwise , stirred at room temperature for 45 minutes to obtain a clear solution 1; 2.1711 g of barium acetate was dissolved in deionized water, and added dropwise to the clear solution 1 at a temperature of 55 ° C, and stirred for 1 hour to obtain a homogeneous solution 2; 0.4293 g of zirconium nitrate and 0.3542g of calcium nitrate were dissolved in deionized water respectively, and were added to solution 2 in the order of adding dropwise zirconium nitrate first and then calcium nitrate, and stirred at a temperature of 80°C for 40 minutes to obtain a uniform and stable chelate sol; The sol was coked in a muffle furnace at 380°C for 1.5 hours to obtain a ...

Embodiment 2

[0045] Preparation of Ba 0.85 Ca 0.15 Ti 0.95 Zr 0.05 o 3 Ceramics: Dissolve 3.2334g of tetrabutyl titanate in a mixed solution of 8ml of alcohol and 13ml of ethylene glycol, and stir thoroughly at room temperature for 1 hour; add the mixed solution of 6.6544g of citric acid and 2.9178g of alcohol dropwise to the above solution, Stir at room temperature for 45 minutes to obtain a clear solution 1; 2.1711 g of barium acetate was dissolved in deionized water, and added dropwise to a temperature of 55 ° C in the clear solution 1, and stirred for 1 hour to obtain a homogeneous solution 2; 0.2147 g of zirconium nitrate was mixed with 0.3542g of calcium nitrate was dissolved in deionized water respectively, and added to solution 2 in the order of first adding zirconium nitrate dropwise and then adding calcium nitrate dropwise, and stirring at a temperature of 80°C for 40 minutes to obtain a uniform and stable chelate sol; Coke in a muffle furnace at 380°C for 1.5 hours to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Piezoelectric coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com