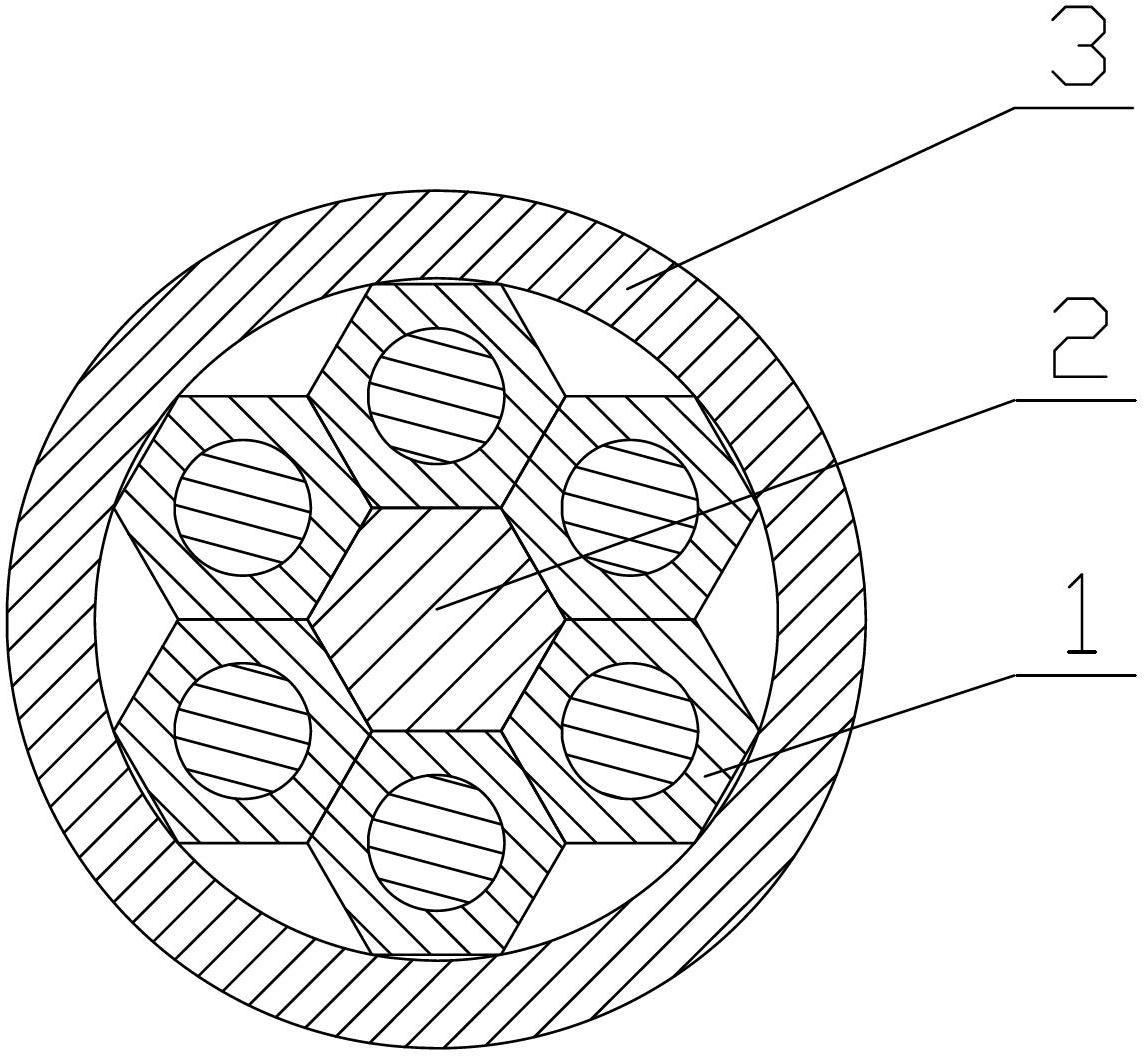

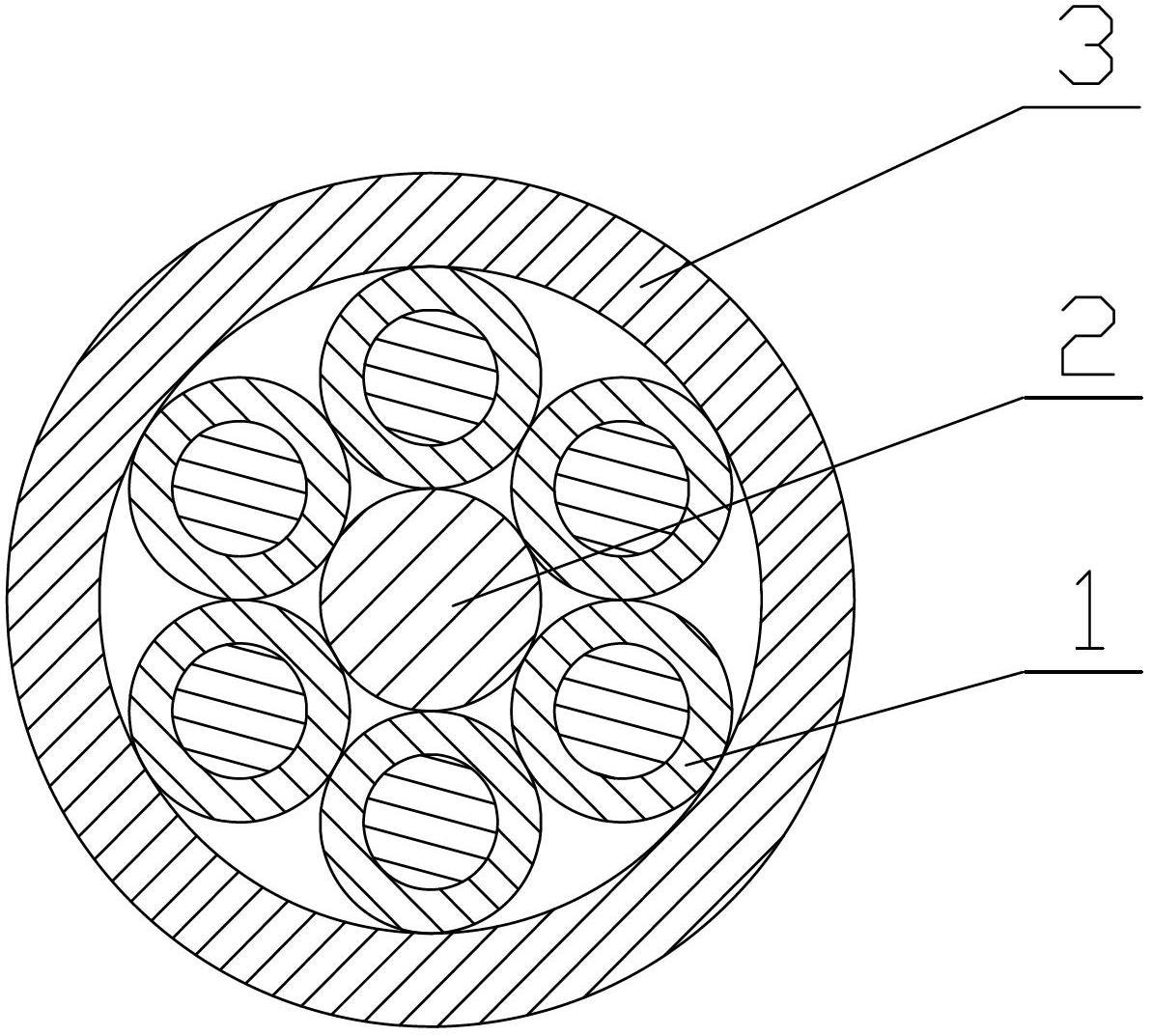

Preparation method for multi-core MgB2/Fe/Cu superconducting wire

A superconducting wire and wire technology, applied in the usage of superconductor elements, cable/conductor manufacturing, superconducting devices, etc., can solve the problems of core wire cracks, wire performance degradation, etc., to ensure deformation, improve density, improve Effect of current carrying performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Step 1. Magnesium powder (particle size is -325 mesh, mass purity 99%), amorphous boron powder (mass purity above 99%) and TiC powder (mass purity 99%, particle size not greater than 1μm) according to Mg: The atomic ratio of B:TiC=1:1.96:0.04 is mixed, mixed evenly and pressed into a block, and then the block is placed in a mixed atmosphere of argon and hydrogen (the volume percentage of argon in the mixed atmosphere is 90%, The remainder is hydrogen) under the protection of heat treatment at 850℃ for 3 hours. After cooling, use an agate mortar to manually crush the block for 20 minutes. Put the crushed block into the agate tank, and follow the broken block and agate ball. Put the agate ball in the mass ratio of 1:10, ball mill at 500rpm for 3h, put the ball milled powder into a 200 mesh filter sieve for sieving, retain the sieved powder, remove the upper part of the sieve, and finally sieve Add a mixed powder of magnesium powder and boron powder with a mass of 8% of the...

Embodiment 2

[0041] Step 1. Magnesium powder (particle size is -325 mesh, mass purity 99%), amorphous boron powder (mass purity above 99%) and TiC powder (mass purity 99%, particle size not greater than 1μm) according to Mg: The atomic ratio of B:TiC=1:1.92:0.08 is mixed, mixed evenly and pressed into a block, and then the block is placed in a mixed atmosphere of argon and hydrogen (the volume percentage of argon in the mixed atmosphere is 95%, The remainder is hydrogen) under the protection of heat treatment at 950℃ for 1h. After cooling, use an agate mortar to manually crush the block for 30 minutes. Put the crushed block into an agate tank, according to the crushed block and agate ball Put the agate ball in the mass ratio of 1:15, ball mill at 400rpm for 1h, put the ball milled powder into a 325 mesh filter sieve for sieving, retain the sieved powder, remove the upper part of the sieve, and finally sieve Add a mixed powder of magnesium powder and boron powder with a mass of 15% by mass o...

Embodiment 3

[0048] Step 1. Magnesium powder (particle size is -325 mesh, mass purity 99%), amorphous boron powder (mass purity above 99%) and TiC powder (mass purity 99%, particle size not greater than 1μm) according to Mg: The atomic ratio of B:TiC=1:1.94:0.06 is mixed, mixed evenly and pressed into a block, and then the block is placed in a mixed atmosphere of argon and hydrogen (the volume percentage of argon in the mixed atmosphere is 92%, The remainder is hydrogen) under the protection of heat treatment at 900℃ for 1.5h. After cooling, use an agate mortar to manually crush the block for 25min. Put the crushed block into an agate tank, according to the crushed block and agate The mass ratio of the ball is 1:12 into the agate ball, ball milled at 450 rpm for 2 hours, the ball milled powder is put into a 300 mesh filter sieve for sieving, the sieved powder is retained, the upper part of the sieve is removed, and finally passed Add a mixed powder of magnesium powder and boron powder with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com