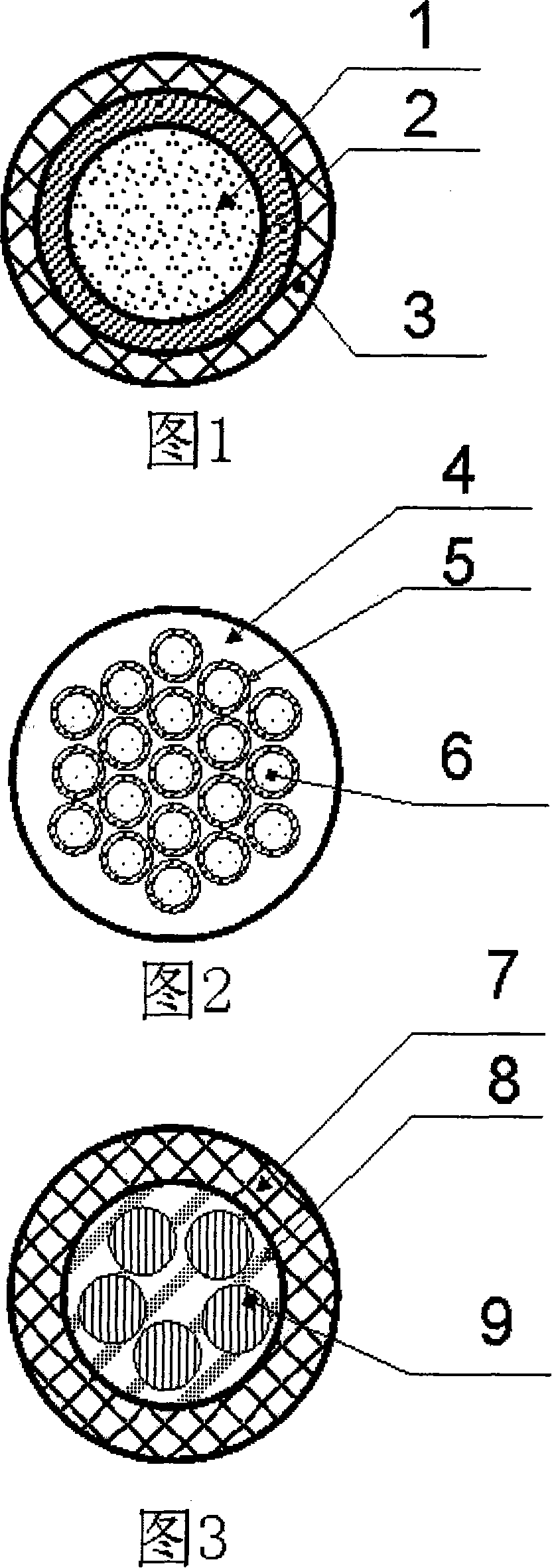

High performance Fe/Cu wrapping structure magnesium diboride multiple core superconductive wire preparation method

A magnesium diboride, high-performance technology, applied in the field of magnesium diboride superconducting wire preparation, can solve the problems affecting the structure and performance of the superconducting wire core, the large amount of mechanical tensile deformation, and affecting the composite interface state, etc., to achieve It is convenient for industrial application, the effect of mechanical tensile resistance is large, and the equipment is easy to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) To process iron pipes and copper pipes with a certain diameter, it is required that the Fe pipes can be tightly inserted into the Cu pipes. Carry out chemical polishing treatment on the inner and outer surfaces of Cu tube and Fe tube, and then clean them;

[0031] (2) Put the Fe pipe into the Cu pipe, then carry out mechanical swaging to the iron / copper pipe to obtain the iron / copper composite pipe;

[0032] (3) Prepare two types of raw material powders by mixing and ball milling process, the formulas are respectively 1) Mg powder and B powder with a molar ratio of 1:2, and 2) Mg powder, B powder and B powder with a molar ratio of 1:2:0.5 Nano NbC powder;

[0033] (4) Pack the raw material powder not containing doping material and the doping material raw material powder containing nano-NbC powder into the iron / copper composite tube respectively, compress and seal the port;

[0034](5) Under the condition of single-pass processing deformation rate of 2%, doped sing...

Embodiment 2

[0040] (1) To process iron pipes and copper pipes with a certain diameter, it is required that the Fe pipes can be tightly inserted into the Cu pipes. In order to make the iron pipes and copper pipes form close contact, the inner and outer surfaces of the Cu pipes and Fe pipes must be chemically polished. , and then cleaned;

[0041] (2) Insert the Fe tube into the Cu tube, and perform mechanical swaging to prepare the iron / copper composite tube;

[0042] (3) Prepare two types of raw material powders by mixing and ball milling process, the raw material formulations are respectively 1) Mg powder and B powder with a molar ratio of 1:2, and 2) Mg powder and B powder with a molar ratio of 1:2:0.5 and nano C powder;

[0043] (4) Pack the raw material powder not containing doping material and the doping material raw material powder containing nano-C powder into the iron / copper composite tube respectively, compress and seal the port;

[0044] (5) Under the condition of processing d...

Embodiment 3

[0050] (1) To process iron pipes and copper pipes of a certain diameter, it is required that the Fe pipe can be tightly inserted into the Cu pipe, and the inner and outer surfaces of the Cu pipe and Fe pipe are chemically polished, and then cleaned;

[0051] (2) Fe tubes are inserted into Cu tubes, and then iron / copper tubes are mechanically swaged to prepare iron / copper composite tubes;

[0052] (3) Prepare two types of raw material powders by mixing and ball milling process, the raw material formulations are respectively 1) Mg powder and B powder with a molar ratio of 1:2, and 2) Mg powder and B powder with a molar ratio of 1:2:0.5 and magnesium stearate;

[0053] (4) Pack the raw material powder not containing magnesium stearate doping material and the raw material powder containing doping material into the iron / copper composite tube respectively, compress and seal the port;

[0054] (5) Under the condition of processing deformation rate of 7% in each pass, two kinds of do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com