Method for preparing multicore TiC doped with MgB2 superconductive material by in situ method

An in-situ method and tape technology, applied in cable/conductor manufacturing, usage of superconductor elements, superconducting devices, etc. Silk is easy to produce microcracks and other problems, to achieve the effect of improving metal fluidity, good chemical inertness, and avoiding diffusion behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

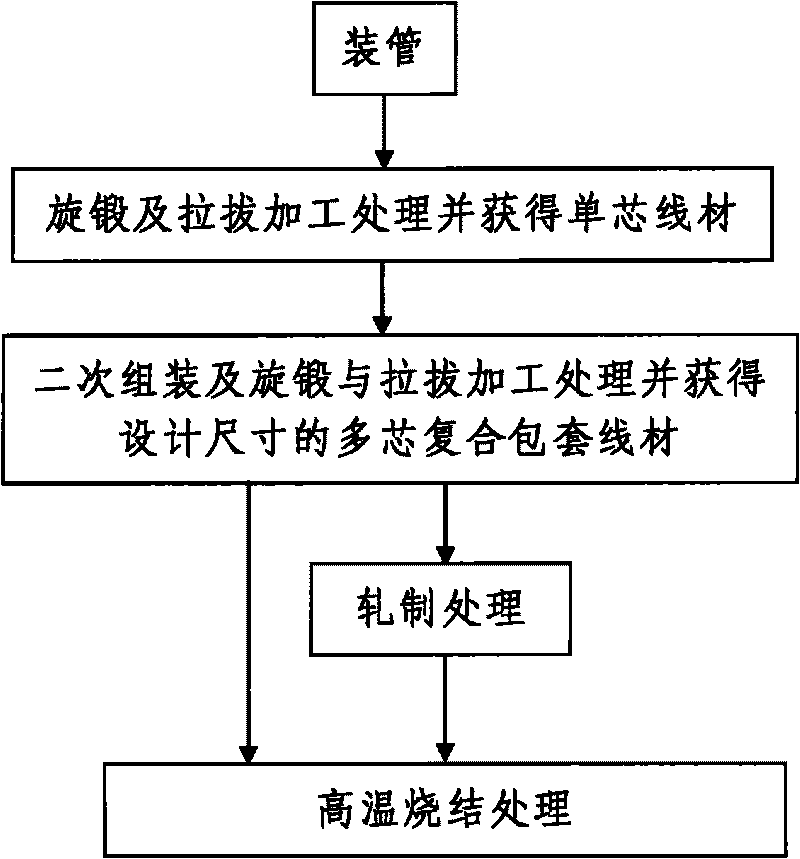

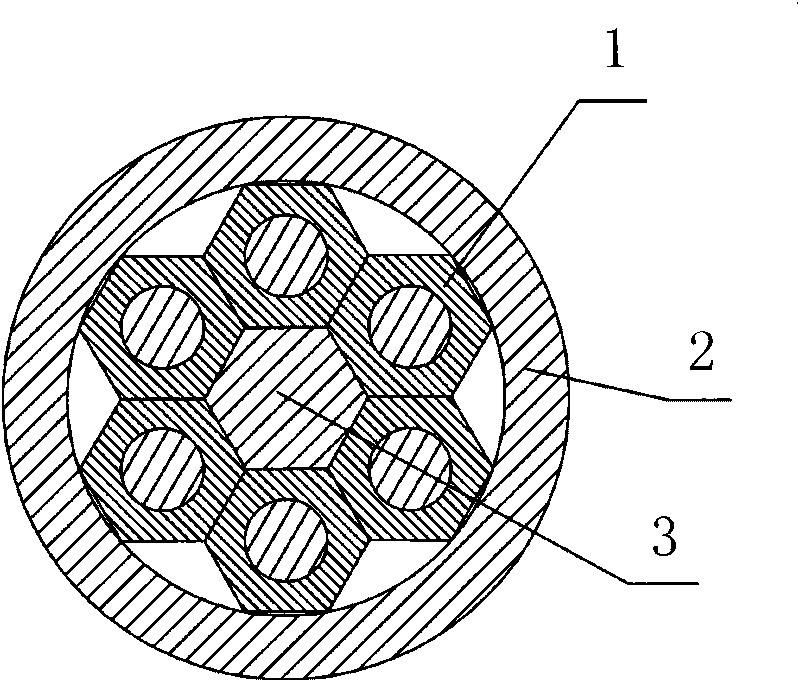

[0048] combine figure 2 , in this example, multi-core TiC doped MgB was prepared by in-situ method 2 When stripping, the following steps are involved:

[0049] Step 1, tube loading: First, fully mix dry magnesium powder, high-purity crystalline boron powder and nano-titanium carbide powder according to the ratio of atomic numbers of 1:1.95:0.05 to obtain a mixture, and then put the mixture into Into the Nb / Cu composite metal pipe that has been pickled in advance to obtain a pipe-loading composite; the Nb / Cu composite metal pipe is made of an inner tube made of Nb material and coaxially sleeved on the outside of the inner tube and Consists of an outer tube made of Cu material. The purity of the magnesium powder, the high-purity crystalline boron powder and the nano-titanium carbide powder are respectively 99.8%, 99.999% and 99.9%. The pickling treatment described in step 1 is pickling with a mixed acid composed of nitric acid and hydrofluoric acid, and after pickling, dehyd...

Embodiment 2

[0058] In this example, the difference from Example 1 is: when loading the tube in step 1, dry magnesium powder, high-purity crystalline boron powder and nano-titanium carbide powder are fully mixed according to the atomic number ratio of 1:1.90:0.1 The mixture is obtained; in step 302, when performing secondary swaging and drawing processing, the pass processing rate is 20%, and a 6-core composite sheathed wire rod with a diameter of Φ1.0mm is obtained; and in step 302, two After the first swaging and drawing processing, there is no need to carry out rolling treatment, but directly carry out high-temperature sintering treatment on the 6-core composite sheathed wire rod; when performing high-temperature sintering treatment in step 4, first put the 6-core composite sheathed wire rod into Fill the tubular annealing furnace with circulating pure argon, heat the 6-core composite sheathed wire at a heating rate of 30°C / min after 1.5h, keep it warm for 1.5h when the temperature rises...

Embodiment 3

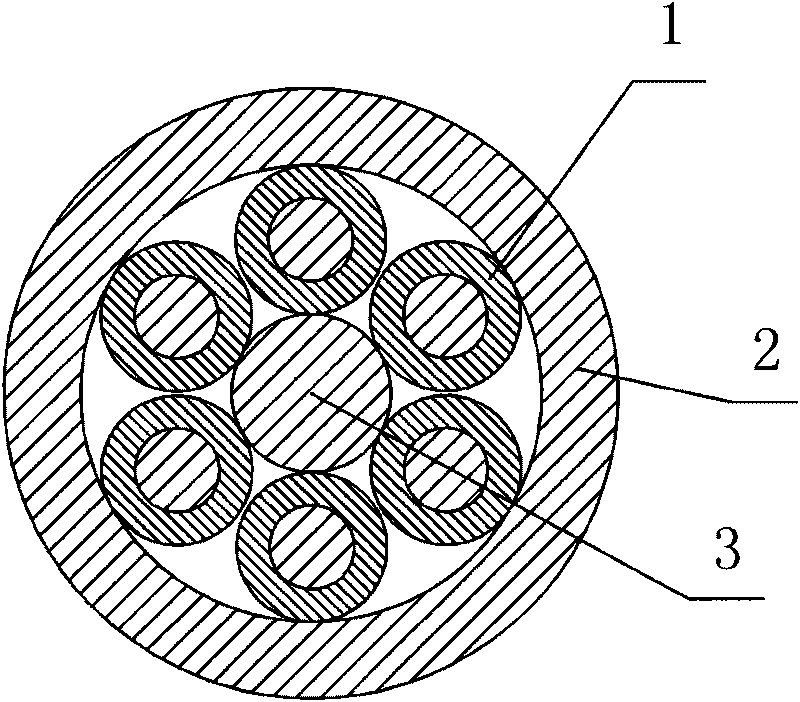

[0060] combine image 3 , in this embodiment, the difference from embodiment 1 is that in step two, a swaging machine and a drawing machine are used to carry out swaging and drawing treatment to the tube-loading complex described in step one successively, and obtain a circular cross-section Shaped single-core wire 1; when performing high-temperature sintering in step 4, first put the 6-core composite sheathed strip into the tubular annealing furnace, fill it with circulating pure argon, and then heat it at 60°C / min after 1.5h The heating rate is to heat the 6-core composite sheathed wire, keep it warm for 0.5h when the temperature rises to 900°C, and finally cool the wire to room temperature at a cooling rate of 45°C / min. In this embodiment, the rest of the process steps, process parameters and preparation process are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com