Preparation method of FeTeSe polycrystalline superconductor

A technology of superconductors and crystal blanks, which is applied in the field of preparation of FeTe1-xSex polycrystalline superconductors, can solve problems such as low critical current density, and achieve the effects of short microwave reaction process, low power consumption, and short synthesis time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

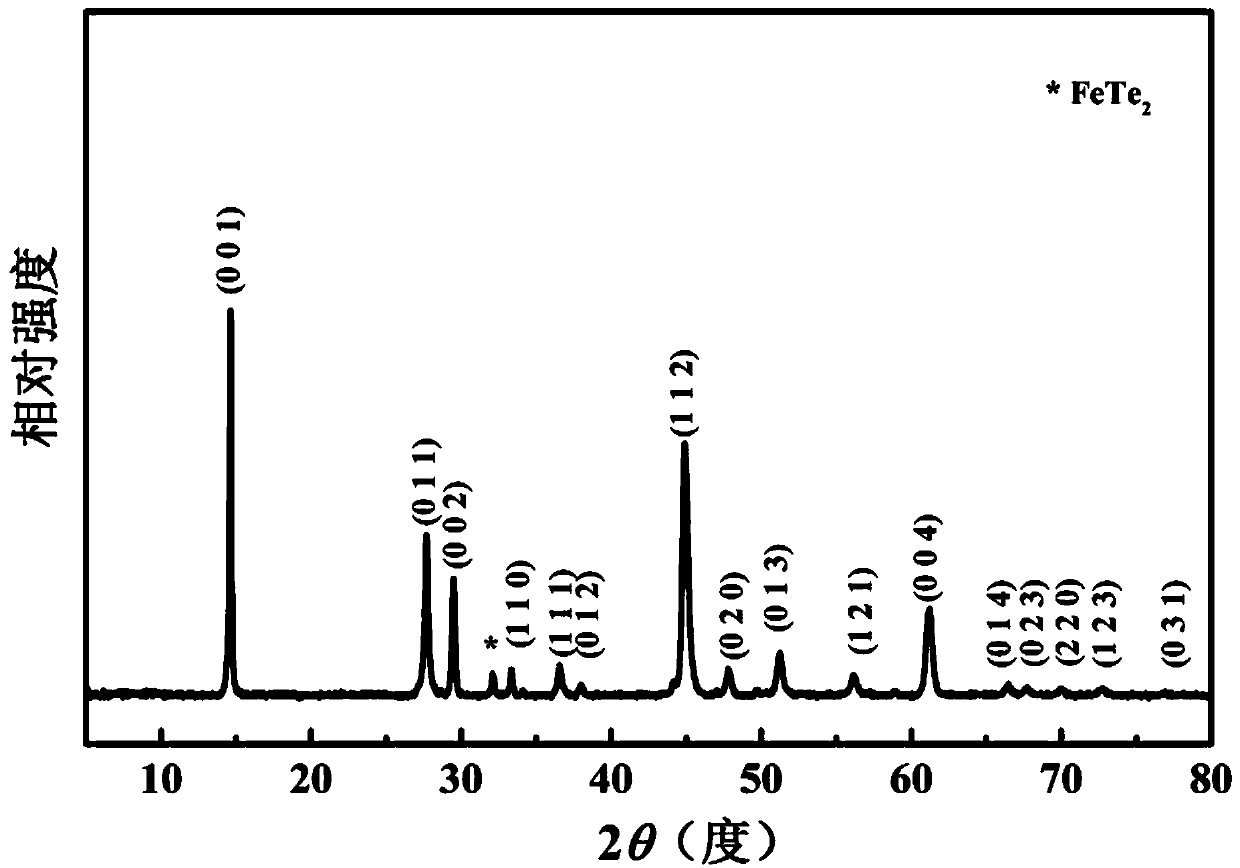

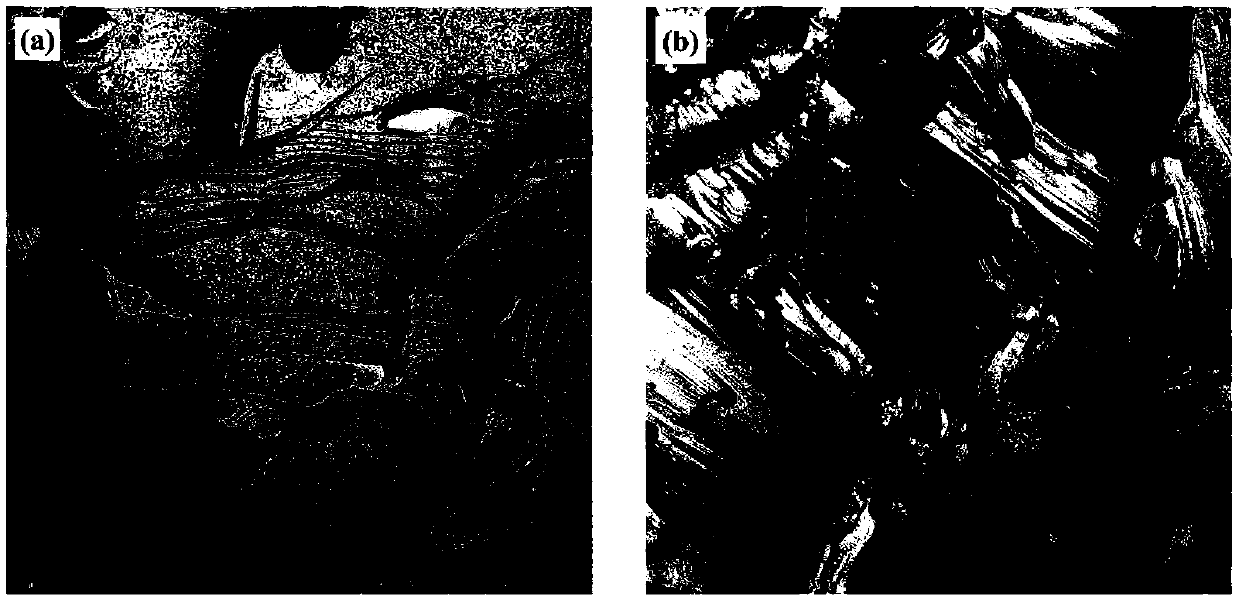

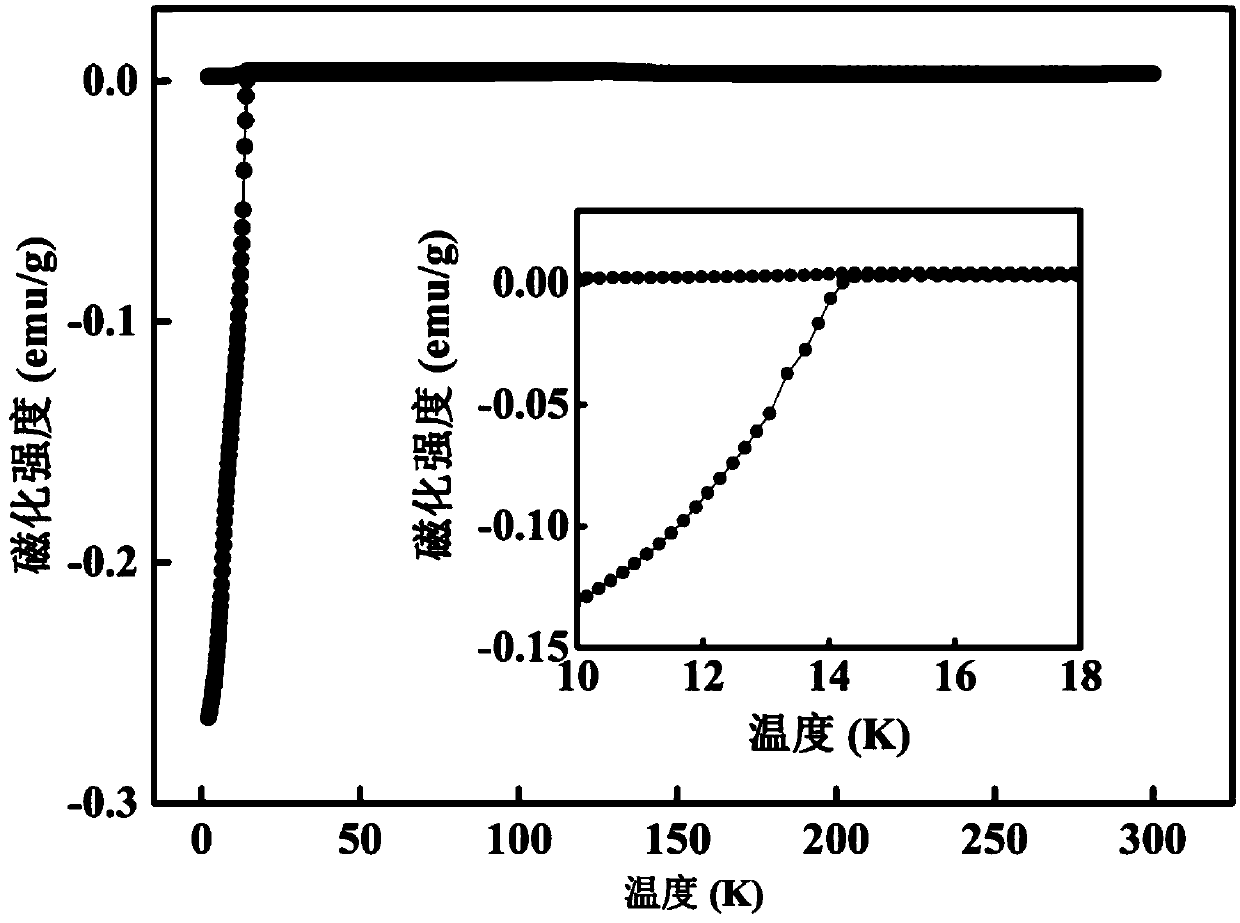

[0030] This example is used to specifically illustrate the preparation method of the FeTeSe polycrystalline superconductor of the present invention.

[0031](1) Mix Fe powder (purity 99.9%), Te powder (purity 99.999%) and Se powder (purity 99.999%) in an atomic ratio of 1:0.6:0.4 and grind them thoroughly for 30 minutes, take out 0.3 grams and put them in In a mold with a diameter of 8 mm, a small piece with a thickness of 1 mm is pressed through the mold under a pressure of 400 MPa, and the small piece is packed into a quartz tube with one end sealed. The quartz tube containing the raw material is evacuated by a molecular pump, and the vacuum degree is 10 -3 Pa or above, and seal the other port with a welding gun to ensure that the sample is in an oxygen-free environment.

[0032] (2) Put the quartz tube sealed with raw materials obtained in step (1) into the center of the cavity of a microwave oven (microwave oven model is EM-310BX, Sanyo), take out the microwave oven turnt...

Embodiment 2

[0050] This example is used to specifically illustrate the preparation method of the FeTeSe polycrystalline superconductor of the present invention.

[0051] (1) Mix Fe powder (purity 99.9%), Te powder (purity 99.999%) and Se powder (purity 99.999%) in an atomic ratio of 1:0.4:0.6 and grind them thoroughly for 30 minutes, take out 0.3 grams and put them in In a mold with a diameter of 8 mm, a small piece with a thickness of 1 mm is pressed through the mold under a pressure of 400 MPa, and the small piece is packed into a quartz tube with one end sealed. The quartz tube containing the raw material is evacuated by a molecular pump, and the vacuum degree is 10 -3 Pa or above, and seal the other port with a welding gun to ensure that the sample is in an oxygen-free environment.

[0052] (2) Put the quartz tube sealed with raw materials obtained in step (1) into the center of the cavity of a microwave oven (microwave oven model is EM-310BX, Sanyo), take out the microwave oven turn...

Embodiment 3

[0057] This example is used to specifically illustrate the preparation method of the FeTeSe polycrystalline superconductor of the present invention.

[0058] (1) Mix Fe powder (purity 99.9%), Te powder (purity 99.999%) and Se powder (purity 99.999%) in an atomic ratio of 1:0.5:0.5 and grind them thoroughly for 30 minutes, take out 0.3 grams and put them in In a mold with a diameter of 8 mm, a small piece with a thickness of 1 mm is pressed through the mold under a pressure of 400 MPa, and the small piece is packed into a quartz tube with one end sealed. The quartz tube containing the raw material is evacuated by a molecular pump, and the vacuum degree is 10 -3 Pa or above, and seal the other port with a welding gun to ensure that the sample is in an oxygen-free environment.

[0059] (2) Put the quartz tube sealed with raw materials obtained in step (1) into the center of the cavity of a microwave oven (microwave oven model is EM-310BX, Sanyo), take out the microwave oven turn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| superconducting critical temperature | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com