Method for preparing high temperature superconducting thin film by chemical process

A high-temperature superconducting thin film, chemical solution method, applied in the use of superconducting elements, superconducting devices, superconducting/high-conducting conductors, etc. problem, to achieve the effect of increasing the critical current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

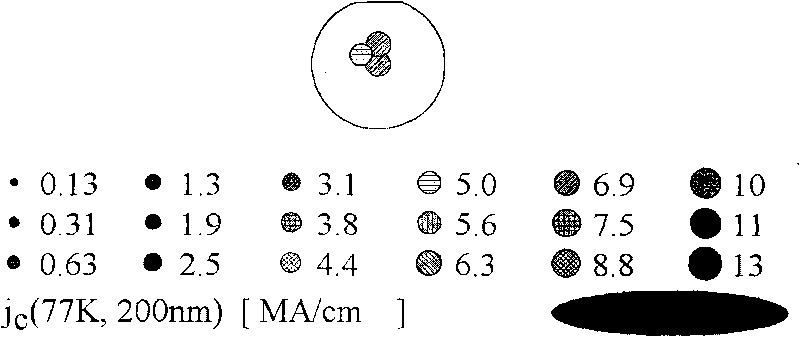

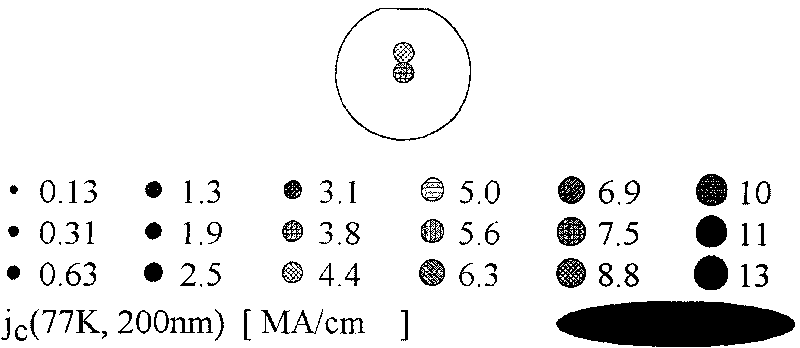

Image

Examples

Embodiment 1

[0023] Y(CH 3 COO) 3 , Sm(CH 3 COO) 3 , Ba(CH 3 COO) 2 and Cu(CH 3 COO) 2 mixed, where Sm(CH 3 COO) 3 accounted for Y(CH 3 COO) 3 The molar content of the solution is 5%, and it is completely dissolved in deionized water containing an equivalent amount of trifluoroacetic acid at room temperature to form a solution, and the concentration of trifluoroacetic acid in the deionized water is 25 mol%.

[0024] The prepared solution was stirred on a magnetic stirrer for 2 hours to improve the uniformity of the solution, and then the solution was vacuum-dried with a rotary evaporator to form a blue gel, then added methanol and stirred to dissolve the gel completely, and then vacuum-dried with a rotary evaporator again It is a blue gel, and methanol is added at the end to make a precursor solution with a total concentration of Y, Sm, Ba and Cu metal ions of 1.5mol / L.

[0025] The prepared precursor solution was spin-coated on LaAlO at 3000 rpm 3 On a single crystal substrate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com