U shaped suspension clamp swaging technique

A hanging clip and U-shaped technology, which is applied in the forging process field of the U-shaped hanging clip, can solve the problems of unqualified products, unqualified strength, creases at the bottom corner of the fork, etc., and the conditions are reasonable and practical. High production efficiency and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] First process the hammer forging die and trimming die.

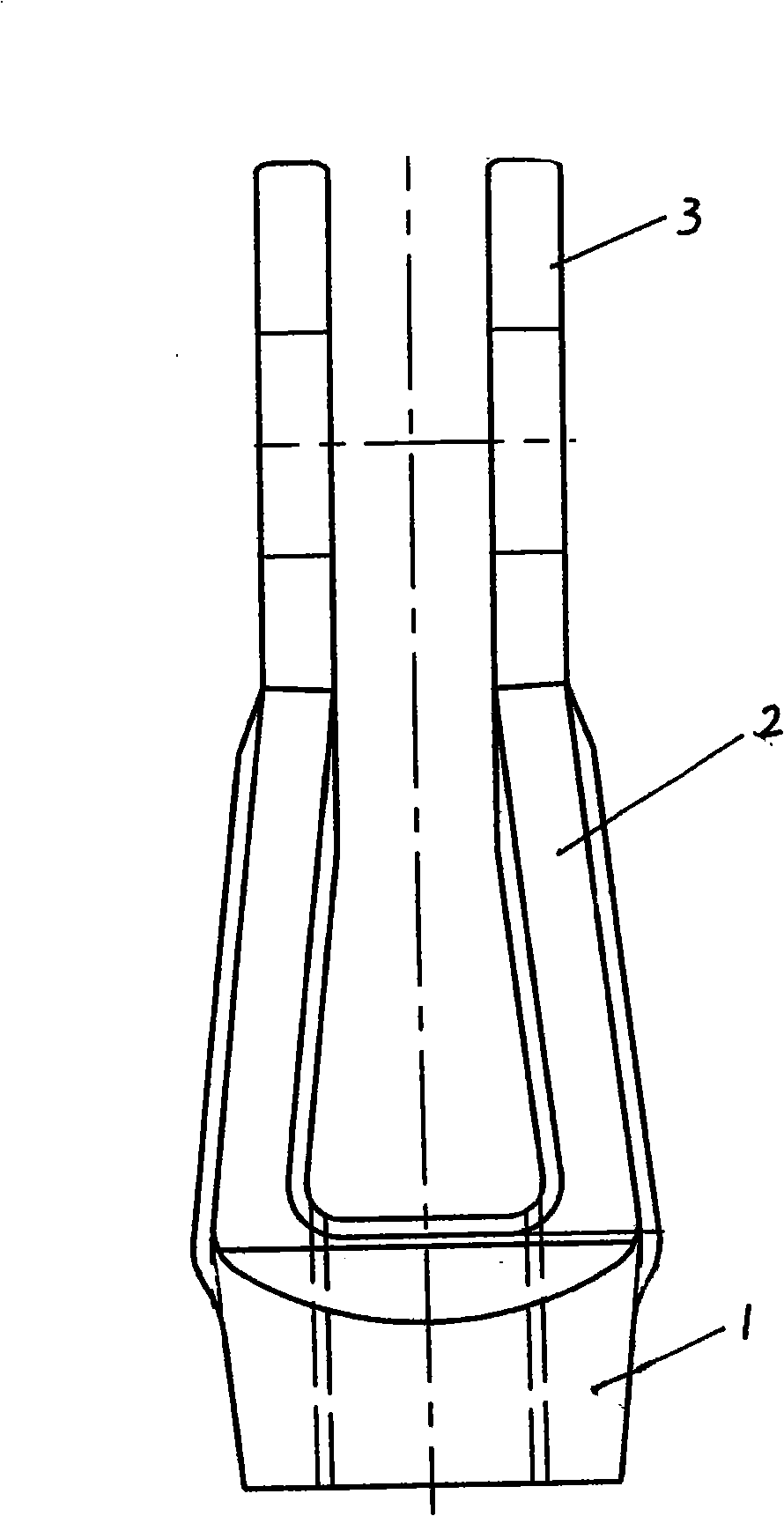

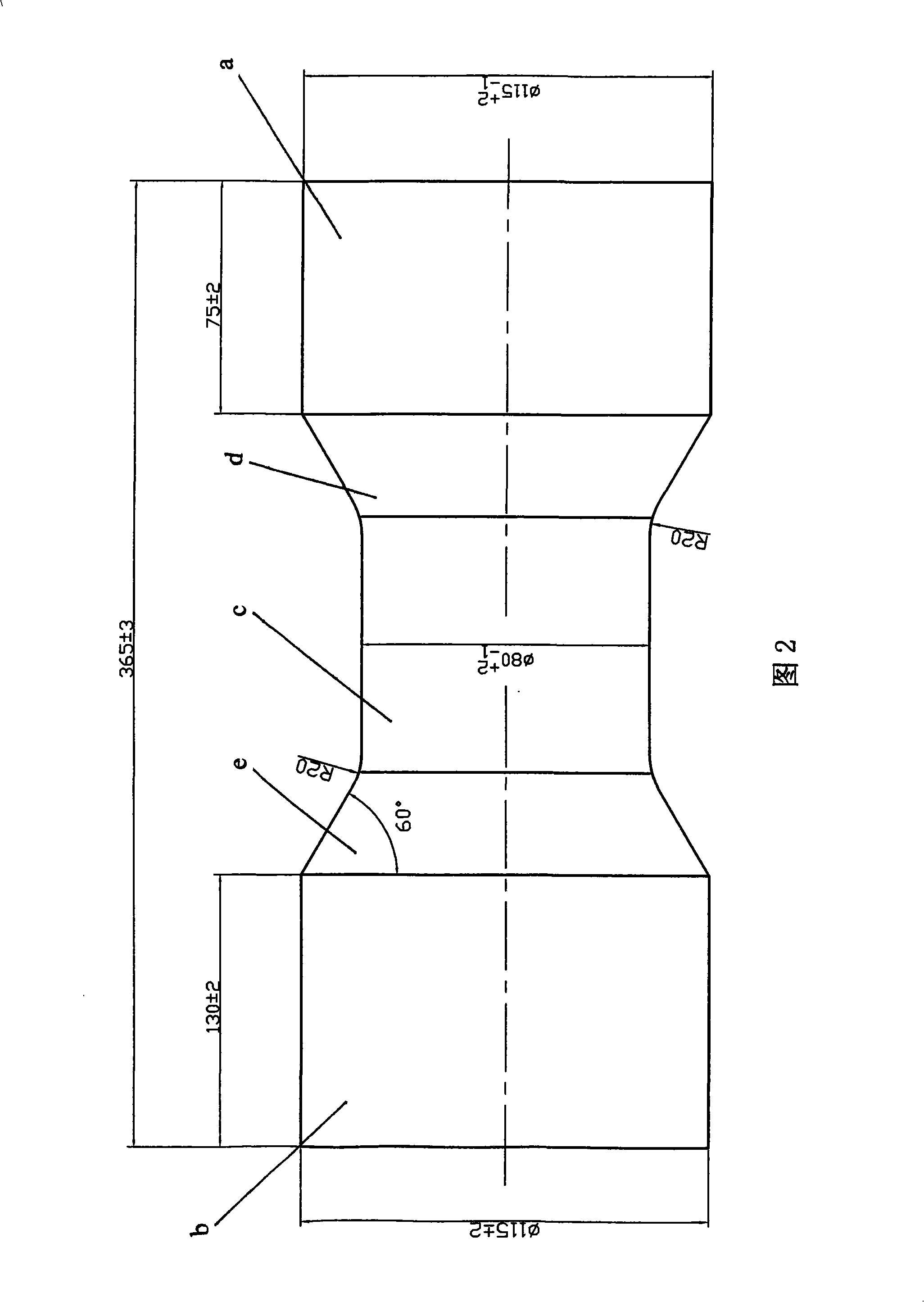

[0039] see Figure 6 : The hammer forging die is composed of an upper die and a lower die. Since the U-shaped hanging clamp product is a symmetrical structure, the parting surface is set on the center line of the forging. This can not only ensure that the appearance of the forging is completely consistent with the product, but also facilitate the forging Full of form. The contour of the mold cavity is basically the same as that of the U-shaped lifting clamp product, but there are forging allowances and draft angles. Considering the difficulty of forgings, the draft angle of the forging is selected to be 7°. For the fork of the U-shaped lifting clamp In the mouth part, it is necessary to facilitate the filling of the lifting lugs and ensure the strength of the mold corresponding to the lifting lugs. Therefore, the inner draft angle is selected as 5°.

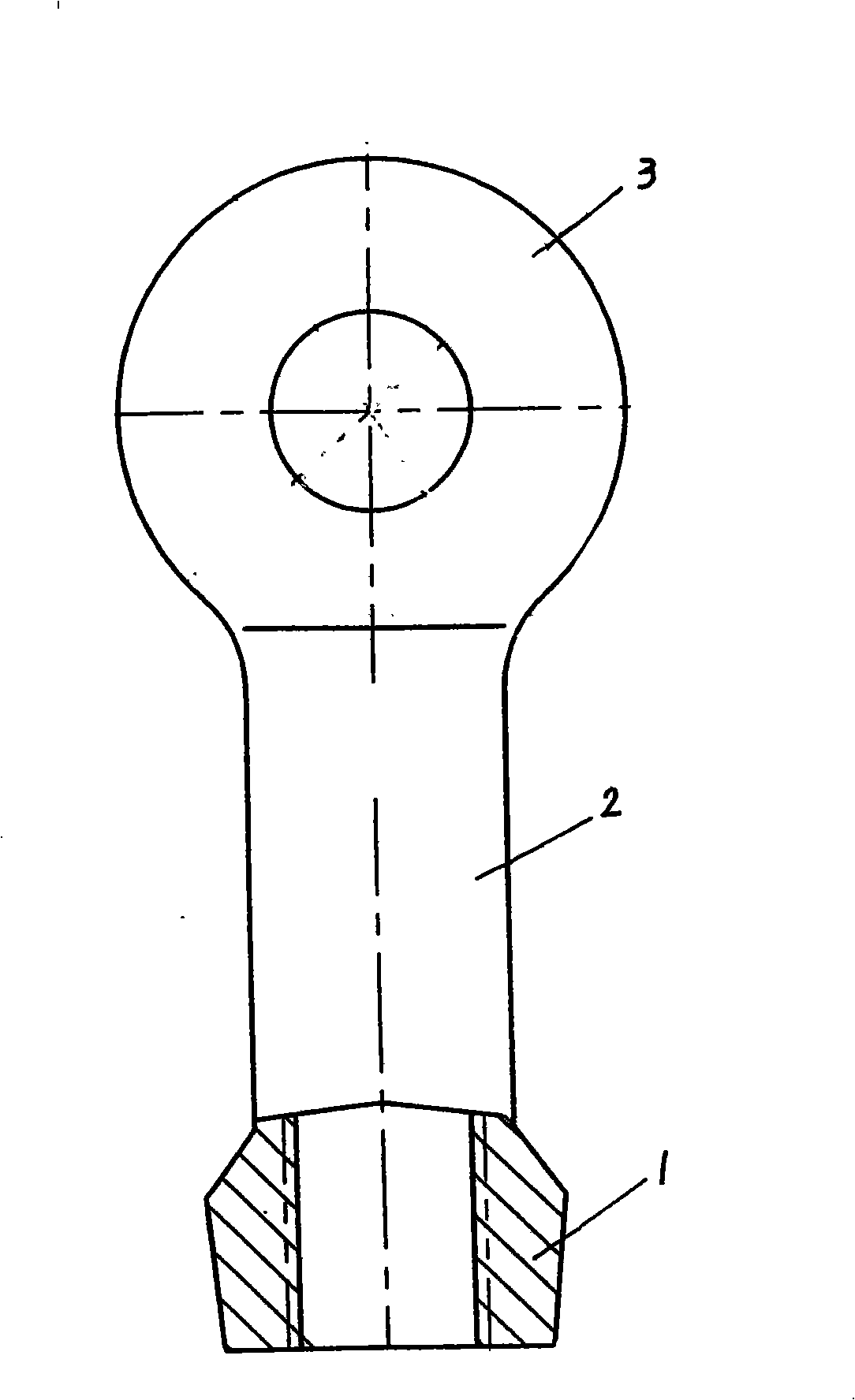

[0040] The earring of the lifting lug has a large diameter an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com