Machining process and tool for shaft with inner step hole with large depth-diameter ratio

A technology of processing technology and aspect ratio, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc. And the problem of uneven wall thickness distribution, long diameter of drilling tools, etc., to save processing economic costs, improve mechanical properties, improve coaxiality and straightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

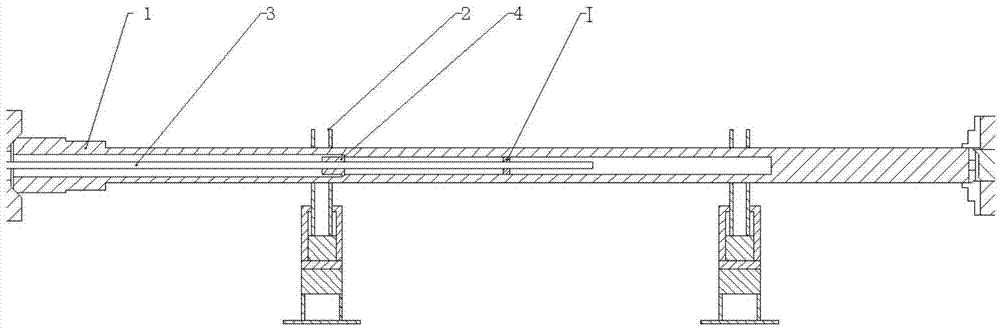

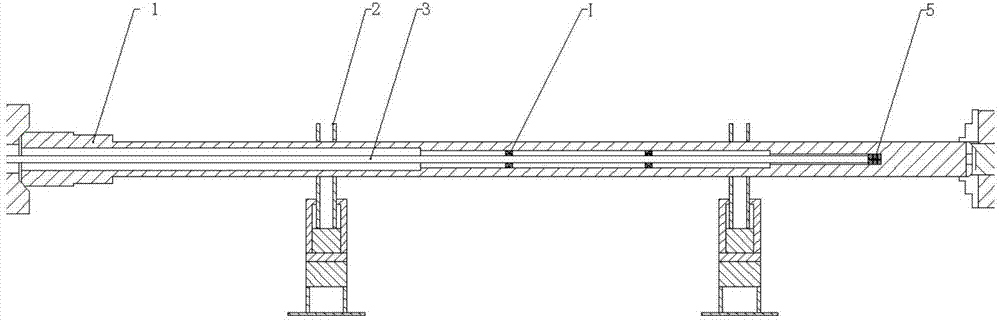

[0043] Further illustrate the present invention below in conjunction with accompanying drawing.

[0044] Taking the shaft of the inner hole of the three-step step as an example, a processing technology of the shaft with a large depth-to-diameter ratio of the stepped inner hole includes the following steps:

[0045] 1) Prepare the workpiece blank: the length of the workpiece blank is L-Δ, where L is the total length value required by the design, and Δ is the forging elongation, which needs to be taken according to the computer numerical simulation and experimental results. circle, drill the center hole, turn the reference outer circle at both ends, chamfer both ends, and get the workpiece 1;

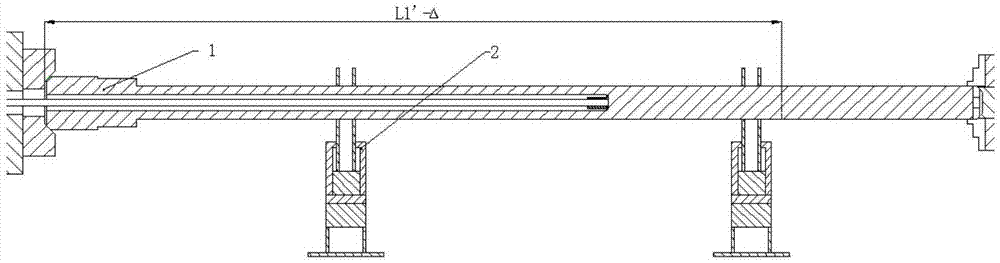

[0046] 2) Drill the middle hole: refer to figure 1 , place the workpiece 1 on the deep space drilling machine, distribute two support frames 2 evenly along the axial direction of the workpiece 1, and then drill the middle hole. The diameter of the drill hole is 0.1-0.2mm larger than the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com