Technology for preparing small-bore and thick-wall metal tubes by rotary swaging technique

A small diameter, metal tube technology, applied in the field of metal pressure processing, to achieve the effect of simple and easy process, high dimensional accuracy, and avoidance of inner wall cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

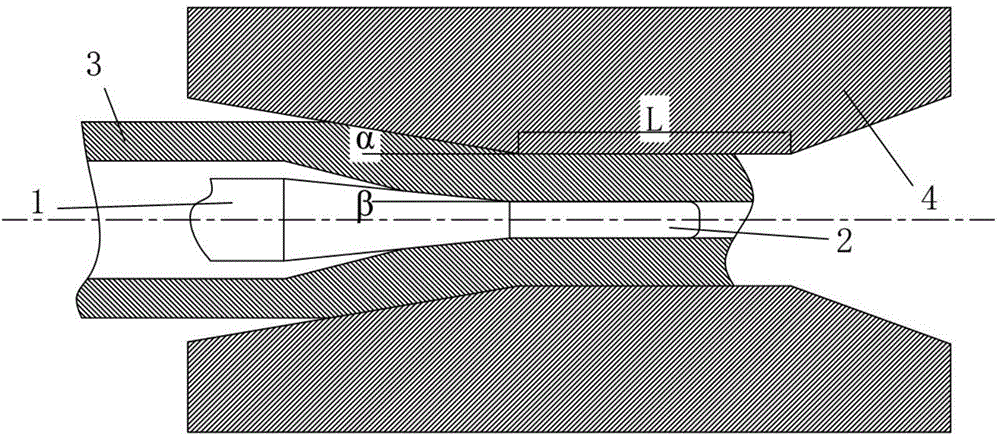

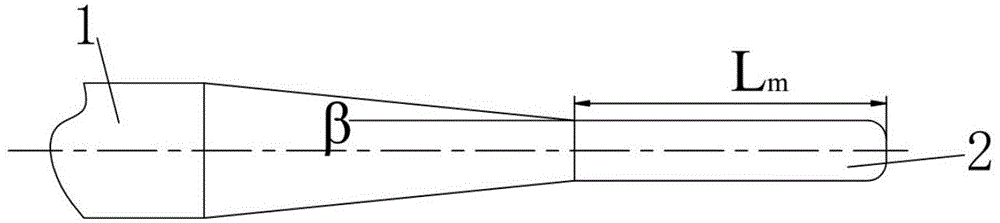

[0025] (1) Choose a copper tube with a size of Φ8×1.5mm as the tube blank, and after pickling, the cut-to-length length is 6m.

[0026] (2) Install the tube blank on the feeding mechanism to ensure that the core mold device passes through the inner hole of the tube blank;

[0027] (3) Feed the core mold device to a fixed position so that the core head part is located in the sizing area of the mold;

[0028] (4) The feeding mechanism sends the tube blank to the rotary forging box for rotary forging;

[0029] The product specification after one pass swaging is Φ5×2mm. Mold cone half angle α=10°, core mold transition cone angle β=8°, core head diameter 1mm, length 20mm, reduction rate of about 37.5%, tube blank feeding speed 0.5m / min, final product dimensional accuracy ±0.02mm ~±0.05mm, the edge of the inner hole is neat and there is no microcrack.

Embodiment 2

[0031] (1) Choose a 304 seamless steel pipe with a size of Φ18×5.5mm as the tube blank, and after pickling, the cut-to-length length is 1m.

[0032] (2) Install the tube blank on the feeding mechanism to ensure that the core mold device passes through the inner hole of the tube blank;

[0033] (3) Feed the core mold device to a fixed position so that the core head part is located in the sizing area of the mold;

[0034] (4) The feeding mechanism sends the tube blank to the rotary forging box for rotary forging;

[0035] The product specification after the first pass of swaging is Φ16×6mm. Mold cone half angle α=8°, core mold transition cone angle β=6°, core head diameter 4mm, length 40mm, diameter reduction rate 11%, tube blank feeding speed 1.5m / min.

[0036] The product specification after the second pass swaging is Φ14×6mm. Mold cone half angle α=8°, core mold transition cone angle β=6°, core head diameter 2mm, length 50mm, diameter reduction rate 12.5%, tube blank feeding speed ...

Embodiment 3

[0038] (1) Choose 20# seamless steel pipe with a size of Φ34×9mm as the tube blank, and after pickling, the cut-to-length length is 0.5m.

[0039] (2) Install the tube blank on the feeding mechanism to ensure that the core mold device passes through the inner hole of the tube blank;

[0040] (3) Feed the core mold device to a fixed position so that the core head part is located in the sizing area of the mold;

[0041] (4) The feeding mechanism sends the tube blank to the rotary forging box for rotary forging;

[0042] The product specification after one rotation forging is Φ30×10mm. Mold cone half angle α=7°, core mold transition cone angle β=5°, core head diameter 10mm, length 60mm, diameter reduction rate about 12%, tube blank feeding speed 0.8m / min, final product dimensional accuracy ±0.05mm ~±0.08mm, the edge of the inner hole is neat and there is no microcrack.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com