Machining method of small-specification high-strength magnesium alloy bars

A processing method and magnesium alloy technology, which is applied in the field of forming and processing of non-ferrous metals, can solve problems such as thermal cracking, narrow deformation temperature range, and grain growth, and achieve short process flow, improved yield strength, and increased tensile strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

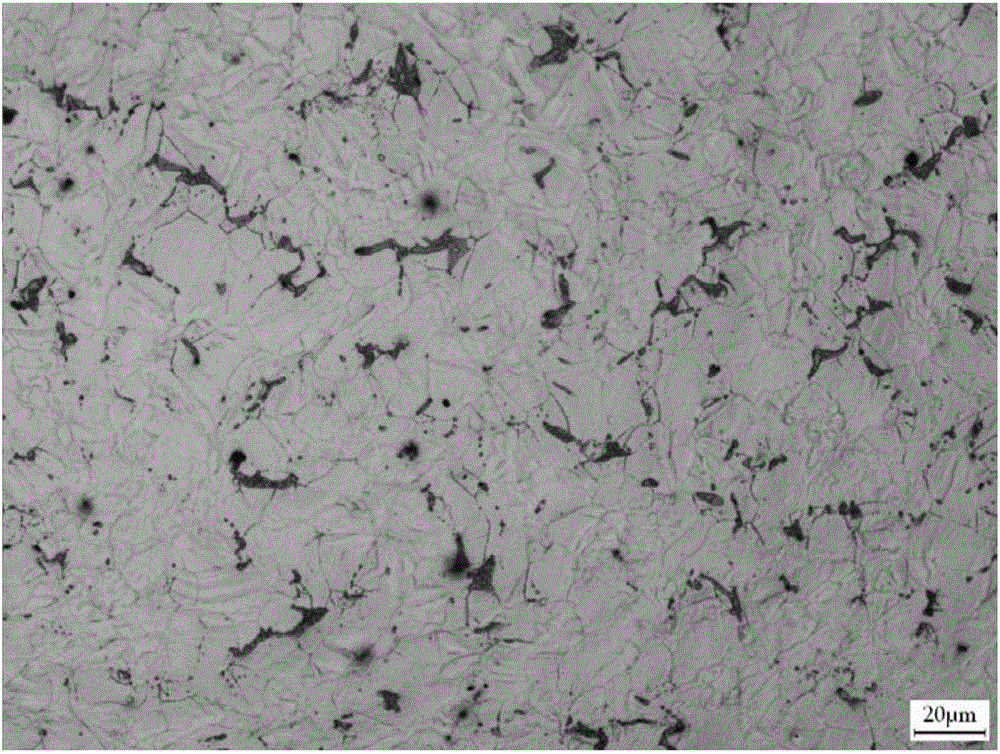

[0021] Taking the AZ61 magnesium alloy bar with a diameter of 4.5mm processed by hot swaging as an example, the method is as follows:

[0022] The AZ61 magnesium alloy billet with a diameter of 12mm is subjected to 4 passes of hot swaging to obtain an AZ61 magnesium alloy rod with a diameter of 4.5mm. The cumulative compression rate of the AZ61 magnesium alloy rod after 4 passes of hot swaging is 85.9%. Before each hot swaging pass, evenly apply a lubricant mixed with graphite powder, molybdenum disulfide and butter according to the mass ratio of 2:1:12.5 on the outside of the magnesium alloy billet, and the feeding speed of hot swaging is 0.2m / min ~1m / min, hot swaging process parameters are shown in Table 1;

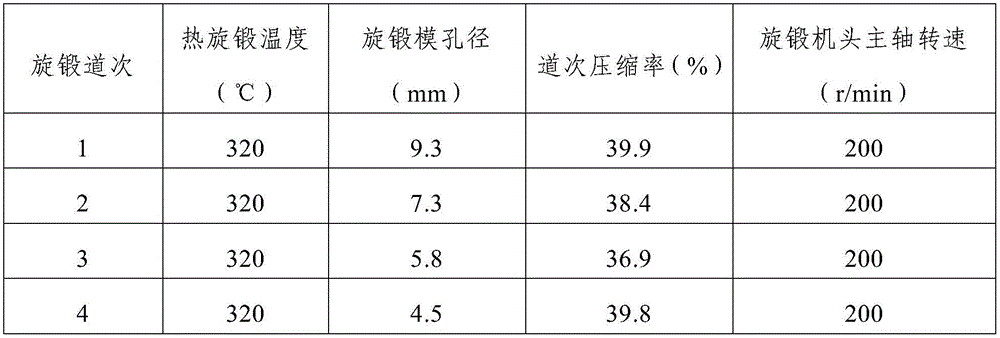

[0023] The hot swaging process parameter of table 1 embodiment 1

[0024]

[0025] After the 1st to 4th passes of hot swaging, the magnesium alloy billet is mechanically polished; after the 3rd pass of hot swaging, the magnesium alloy billet is subjected to an inter...

Embodiment 2

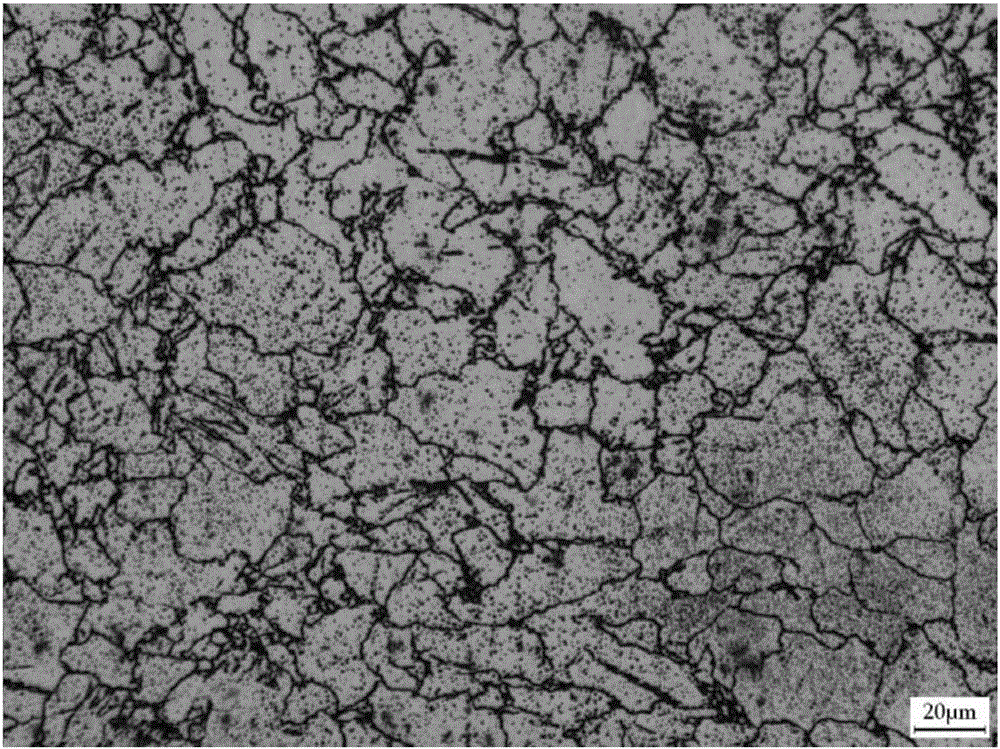

[0028] Taking the hot swaging method to process Mg-2Zn-0.1Ca rods with a diameter of 10mm as an example, the method is as follows:

[0029] The Mg-2Zn-0.1Ca billet with a diameter of 30 mm is subjected to 7 passes of hot swaging to obtain a Mg-2Zn-0.1Ca bar with a diameter of 10 mm. The Mg-2Zn-0.1 after 7 passes of hot swaging The accumulative compression rate of the Ca bar is 88.9%. Before each pass of hot swaging, a lubricant mixed with graphite powder, molybdenum disulfide and butter in a mass ratio of 2:1:15 is evenly applied on the outside of the magnesium alloy billet. The feeding speed of swaging is 0.8m / min~2m / min, and the technical parameters of hot swaging are shown in Table 2;

[0030] The hot swaging process parameter of table 2 embodiment 2

[0031]

[0032]

[0033] After the 1st to 7th passes of hot swaging, the magnesium alloy billet is mechanically polished; after the 4th pass of hot swaging, the magnesium alloy billet is subjected to an intermediate an...

Embodiment 3

[0036] Taking the processing of Mg-5Zn rods with a diameter of 8mm by hot swaging as an example, the method is as follows:

[0037] A Mg-5Zn billet with a diameter of 50 mm is hot swaged 6 times to obtain a Mg-5Zn rod with a diameter of 8 mm. The cumulative compression ratio of the Mg-5Zn rod after 6 times of hot swaging is 84 %, before each pass of hot swaging, evenly apply a lubricant mixed with graphite powder, molybdenum disulfide and butter in a mass ratio of 2:1:15 on the outside of the magnesium alloy billet, and the feeding speed of hot swaging is 0.2m / min~2m / min, hot swaging process parameters are shown in Table 3;

[0038] The hot swaging process parameter of table 3 embodiment 3

[0039]

[0040]

[0041] After the 1st to 11th passes of hot swaging, the magnesium alloy billet is mechanically polished; after the 4th pass of hot swaging, the magnesium alloy billet is subjected to an intermediate annealing treatment at 250 ° C for 60 minutes, and then the surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com