Ultrathin wall sootblower outer sleeve weld joint ultrasound detection method

A technology of ultrasonic detection and soot blower, which is applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, etc., so as to ensure the safe production of electric power, improve the detection rate, and achieve the effect of small cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Ultra-thin-wall sootblower casing weld seam ultrasonic testing method

[0033] 1. Test block, probe and equipment

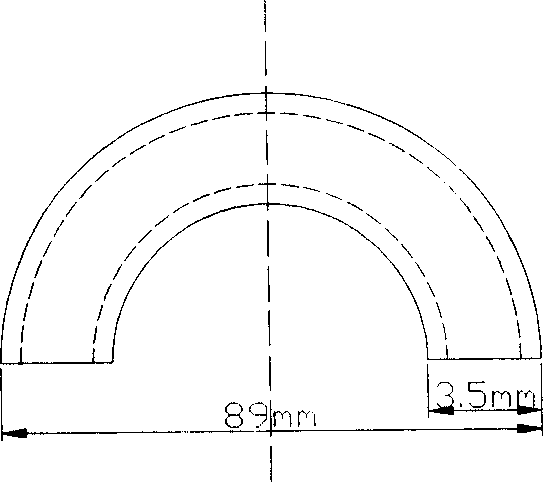

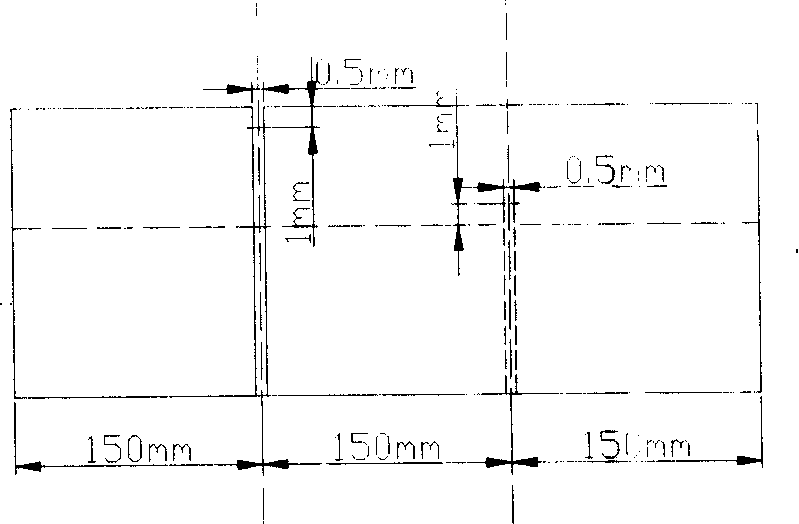

[0034] 1.1 Design of comparative test block: From the analysis of the above stress and failure reasons, the main purpose of inspection is to check out the cracks that appear during operation. In the process of ultrasonic inspection, a simulated crack test block is needed to quantify defects, but there is no such type of comparison test block for parts with material specifications of φ89×3.5 / 1Cr18Ni9Ti.

[0035] Based on this situation, we use the φ89×3.5 / 1Cr18Ni9Ti pipeline to design the following figure 1 The comparison test block shown. The artificial defect is a rectangular groove with a width of 0.5mm and a depth of 1.0mm, and the surface state of the test block is the same as that of the outer casing of the sootblower. figure 1 : Schematic diagram of comparison test block

[0036] 1.2 Probe design refers to the law of end angle reflection. The 45°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com