Cement kiln flue gas dry desulfurization and high dust SCR denitration device and process

A dry desulfurization and cement kiln technology, applied in gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of small total investment and low energy consumption in operation, and achieve no dead ends, saving system resistance, and dust removal thorough effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

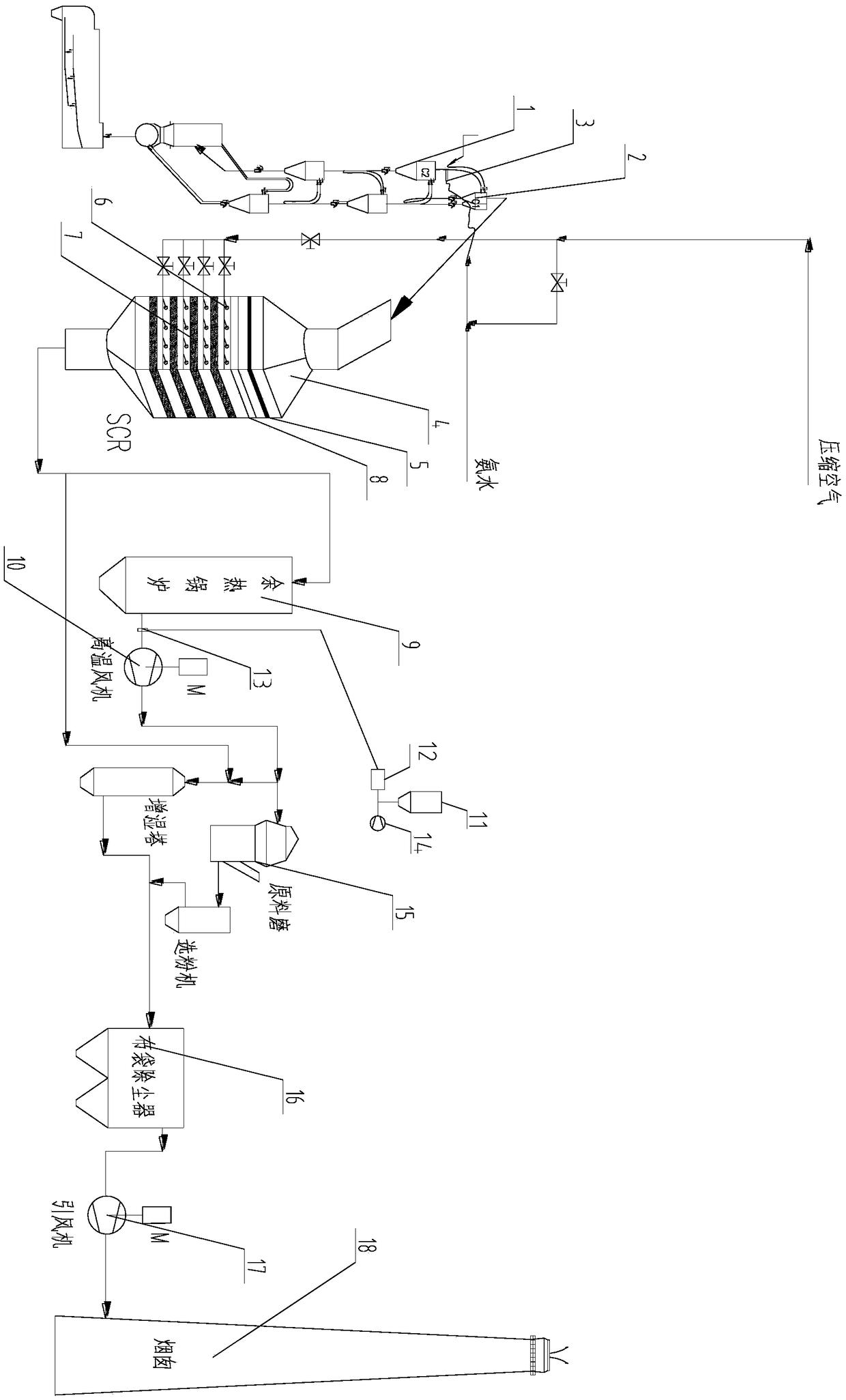

[0021] In order to set forth the specific implementation steps of the present invention more vividly, it will be further described as follows in conjunction with the accompanying drawings:

[0022] Referring to the accompanying drawings, a cement kiln flue gas dry desulfurization and high dust SCR denitrification device includes a desulfurizer powder bin 11, a Roots blower 14, a desulfurizer pulverizer 12, a desulfurizer dosing device 13, and a high dust SCR denitrification Reactor 4, dual-fluid atomizing spray gun 3, desulfurization agent dosing device 13 is installed between the outlet of waste heat boiler 9 at the cement kiln tail and high temperature fan 10, and desulfurization agent dosing device 13 is connected with the desulfurization agent grinding and conveying system , the desulfurizing agent grinding conveying system includes a desulfurizing agent powder bin 11 , a Roots blower 14 and a desulfurizing agent mill 12 . Between the preheater C1 2 of the cement kiln and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com