Soot blower

A technology of soot blower and soot blower, which is used in the treatment of combustion products, combustion methods, and removal of solid residues, etc. Soot and other problems, to achieve the effect of saving soot blowing gas and electric energy, reducing the frequency of soot blowing, and reducing the degree of soot blowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

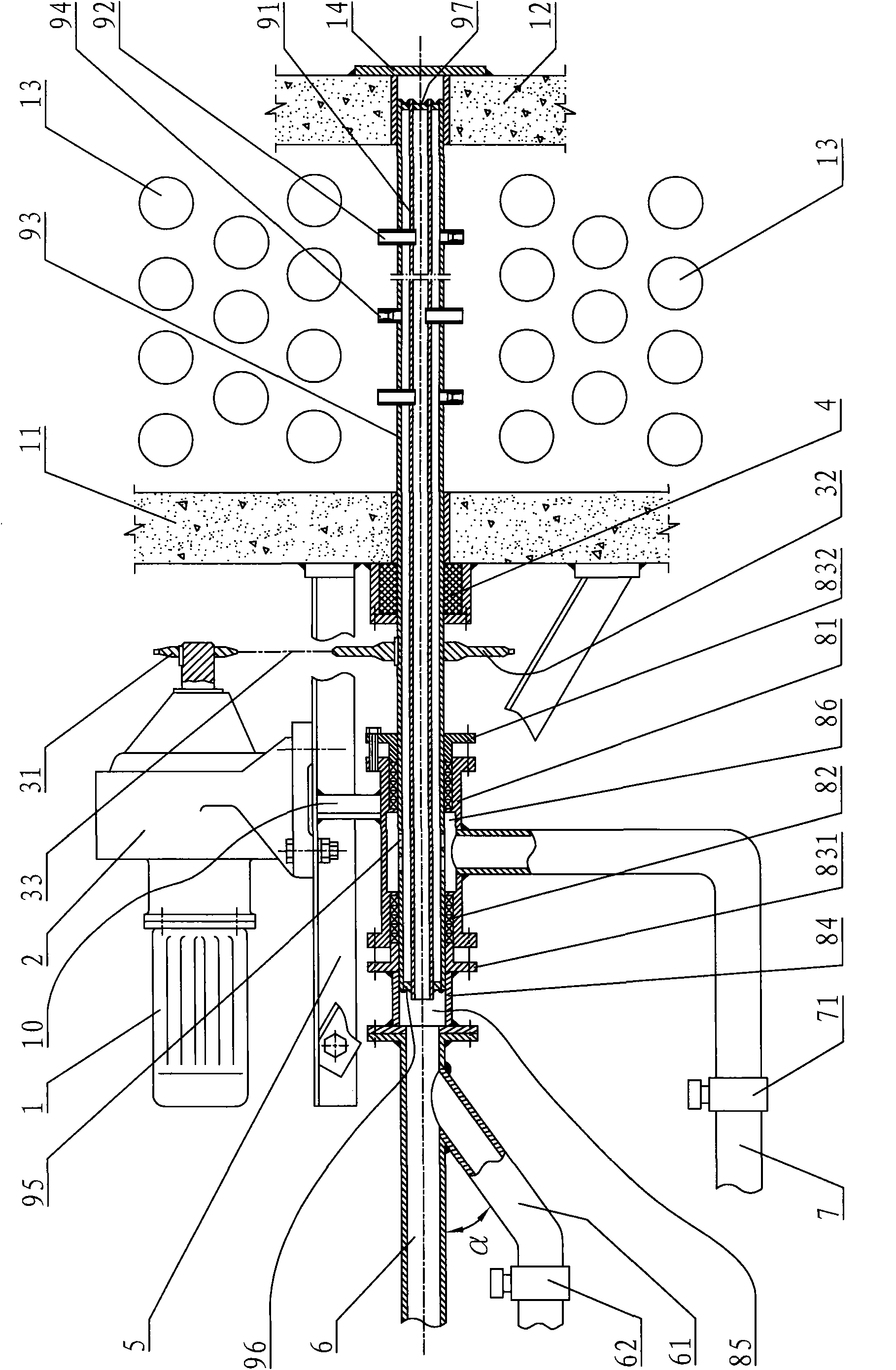

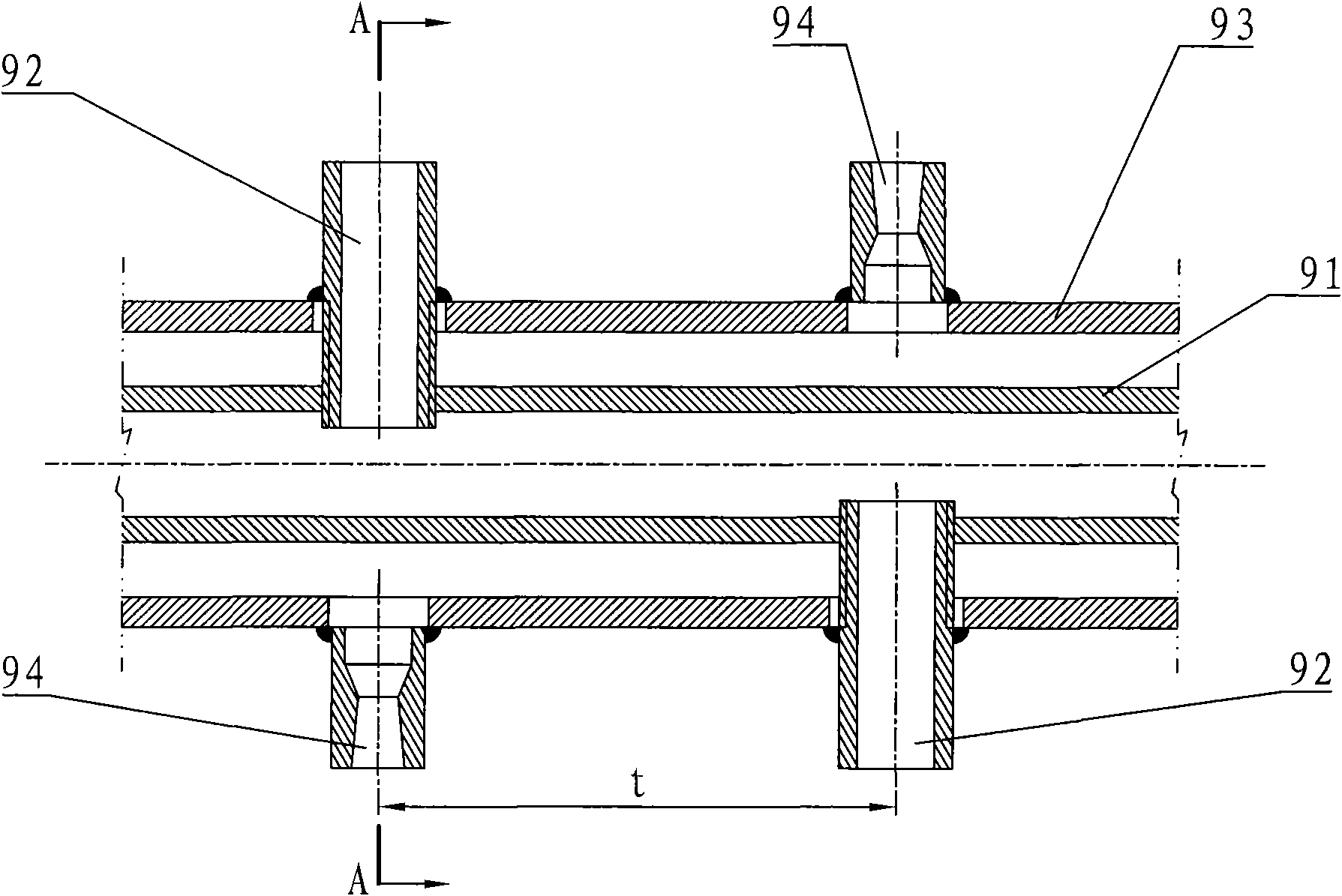

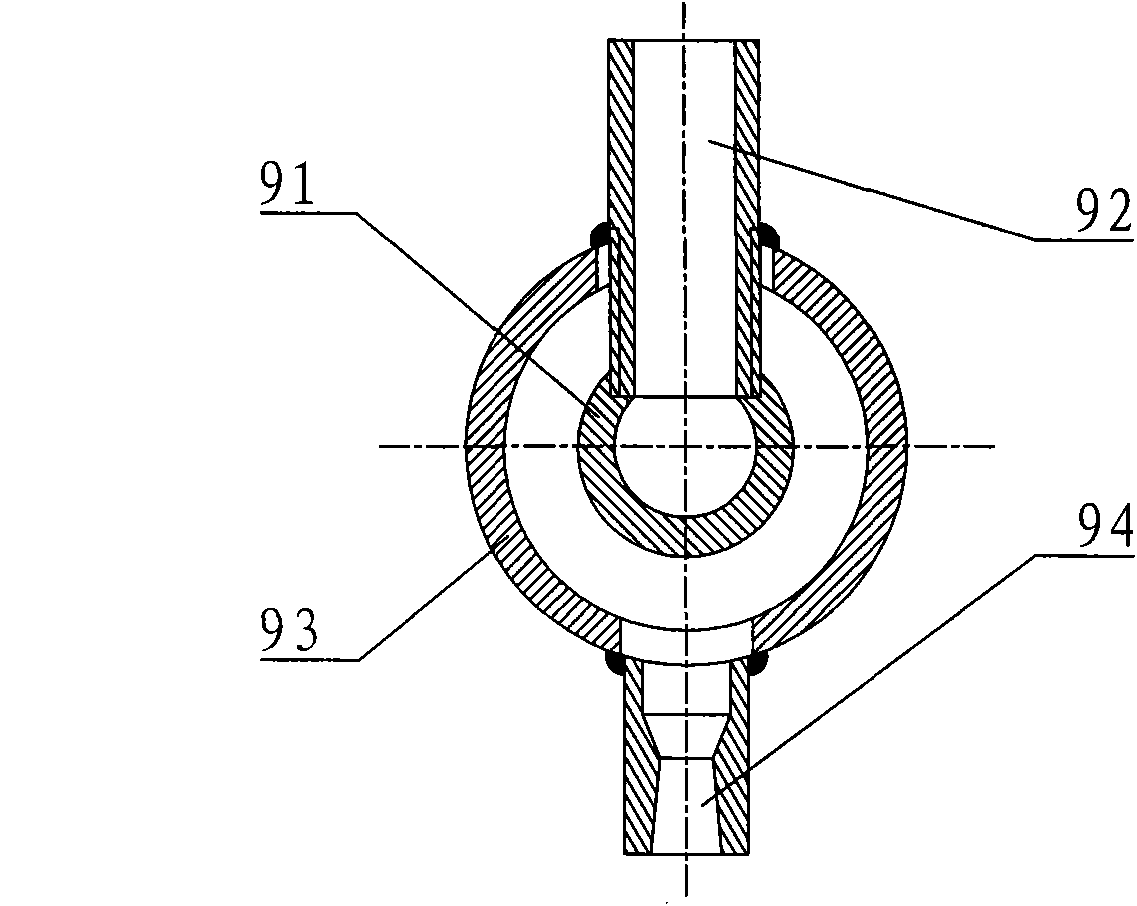

[0019] see figure 1 , figure 2 and image 3 , The soot blower of the present invention is provided with an air intake system, a transmission system, a soot blowing pipe 93 and a support 5 . The transmission system includes a motor 1, a reducer 2, and a chain transmission device. The chain drive is made up of driving sprocket 31 , driven sprocket 32 and chain 33 . The driving sprocket 31 is connected with the output shaft of the speed reducer 2, and the driven sprocket 32 is connected with the soot blowing pipe 93, both of which can be connected by means of a flat key connection; the driven sprocket 32 can also be welded on the soot blowing pipe 93. The diameter of the driven sprocket 32 is generally larger than that of the driving sprocket 31 . The speed reducer 2 of the soot blower is a cycloidal pin wheel speed reducer, which can be of various commonly used types in the industry. The present invention adopts the cycloid reducer because its deceleration ratio is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com