Novel SCR denitration system based on ammonia escape catalytic removal

A technology of ammonia escape and ammonia gas removal, applied in the field of new SCR denitrification system, can solve the problems of large resistance loss, blockage of adsorption and desorption bed, inability to adapt to the operating conditions of power plants, etc., achieve small changes, low cost, and reduce overall operation Cost and Effect of Overhaul

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

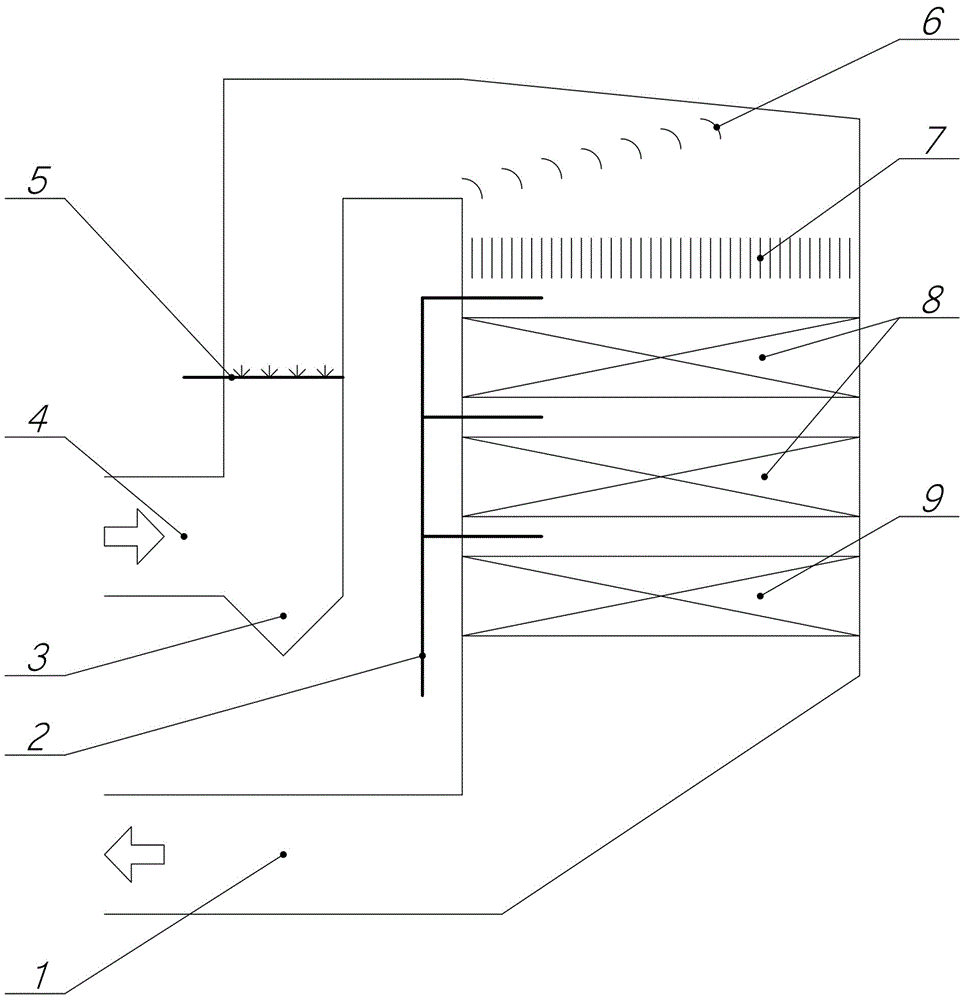

Method used

Image

Examples

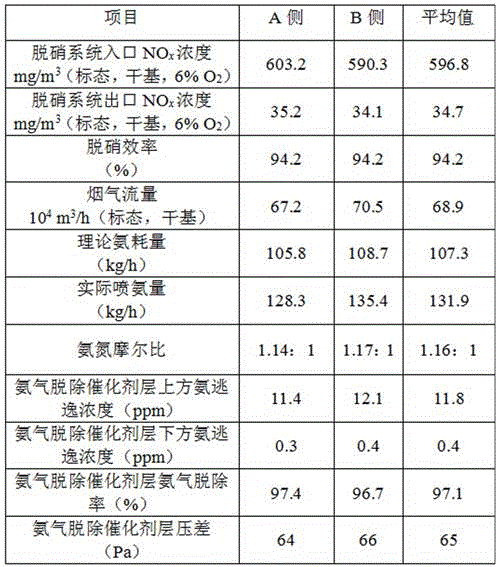

Embodiment 1

[0042] The new SCR denitrification system and process flow used in Example 1 are as described above and will not be repeated. Among them, this embodiment is an overall transformation of the denitration system of a 600MW unit in a coal-fired power plant. On the basis of the original three layers of SCR denitration catalyst layer 8, an additional layer of ammonia gas removal catalyst layer 9 is installed. The ammonia gas removal catalyst layer 9 specifically adopts an ammonia gas decomposition catalyst, the main active component of the ammonia gas decomposition catalyst is a Ru-based compound, and the specification shape of the ammonia gas decomposition catalyst is honeycomb. In order to verify the actual working performance of the new SCR denitrification system based on ammonia slip catalytic removal after modification, the NO in the flue gas x Under the 100% rated load with the maximum concentration and ammonia injection volume, the denitrification performance test of the new ...

Embodiment 2

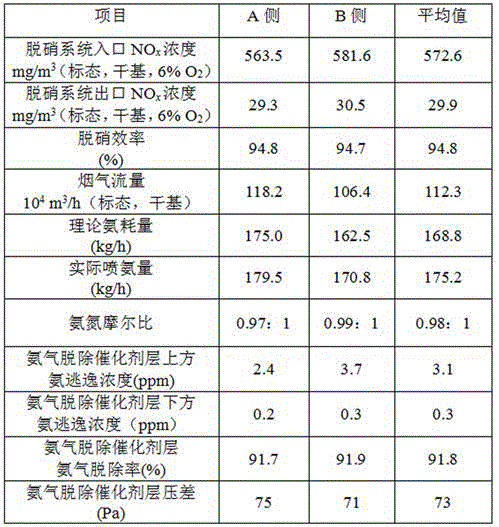

[0047] The new SCR denitrification system and process flow used in Example 2 are the same as those in Example 1, and will not be repeated. Example 2 is an overall transformation of the denitrification system of a 350MW unit in a coal-fired power plant. On the basis of the original three layers of SCR denitration catalyst layer 8, an additional layer of ammonia gas removal catalyst layer 9 is installed. The ammonia gas removal catalyst layer 9 is specifically an ammonia oxidation catalyst, the main active component of which is a modified compound of noble metal Pt, and the specification shape of the ammonia oxidation catalyst is honeycomb.

[0048] In order to verify the actual working performance of the new SCR denitrification system based on ammonia slip catalytic removal after modification, the NO in the flue gas x Under the 100% rated load with the maximum concentration and ammonia injection volume, the denitrification performance test of the new SCR denitrification system ...

Embodiment 3

[0053] The new SCR denitrification system and process flow used in Example 3 are the same as those in Example 2, and will not be repeated. Example 3 is an overall transformation of the denitrification system of a 660MW unit in a coal-fired power plant. On the basis of the original three layers of SCR denitration catalyst layer 8, an additional layer of ammonia gas removal catalyst layer 9 is installed. The ammonia gas removal catalyst layer 9 is specifically an ammonia oxidation catalyst, the main active component of which is a modified compound of noble metal Pt, and the specification shape of the ammonia oxidation catalyst is honeycomb.

[0054] In order to verify the actual working performance of the new SCR denitrification system based on ammonia slip catalytic removal after modification, the NO in the flue gas xThe test was carried out under the condition that the concentration and the amount of ammonia injection changed the most. The load of the unit was reduced from 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com