Operation control system for combustion gas pulse soot blower

A technology of operation control and soot blower, which is applied in the direction of electrical program control, program control in sequence/logic controller, combustion method, etc., can solve the problems of increased failure and large volume of the control system, and achieve the reduction of strength, Effects of improving reliability and reducing temperature and pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

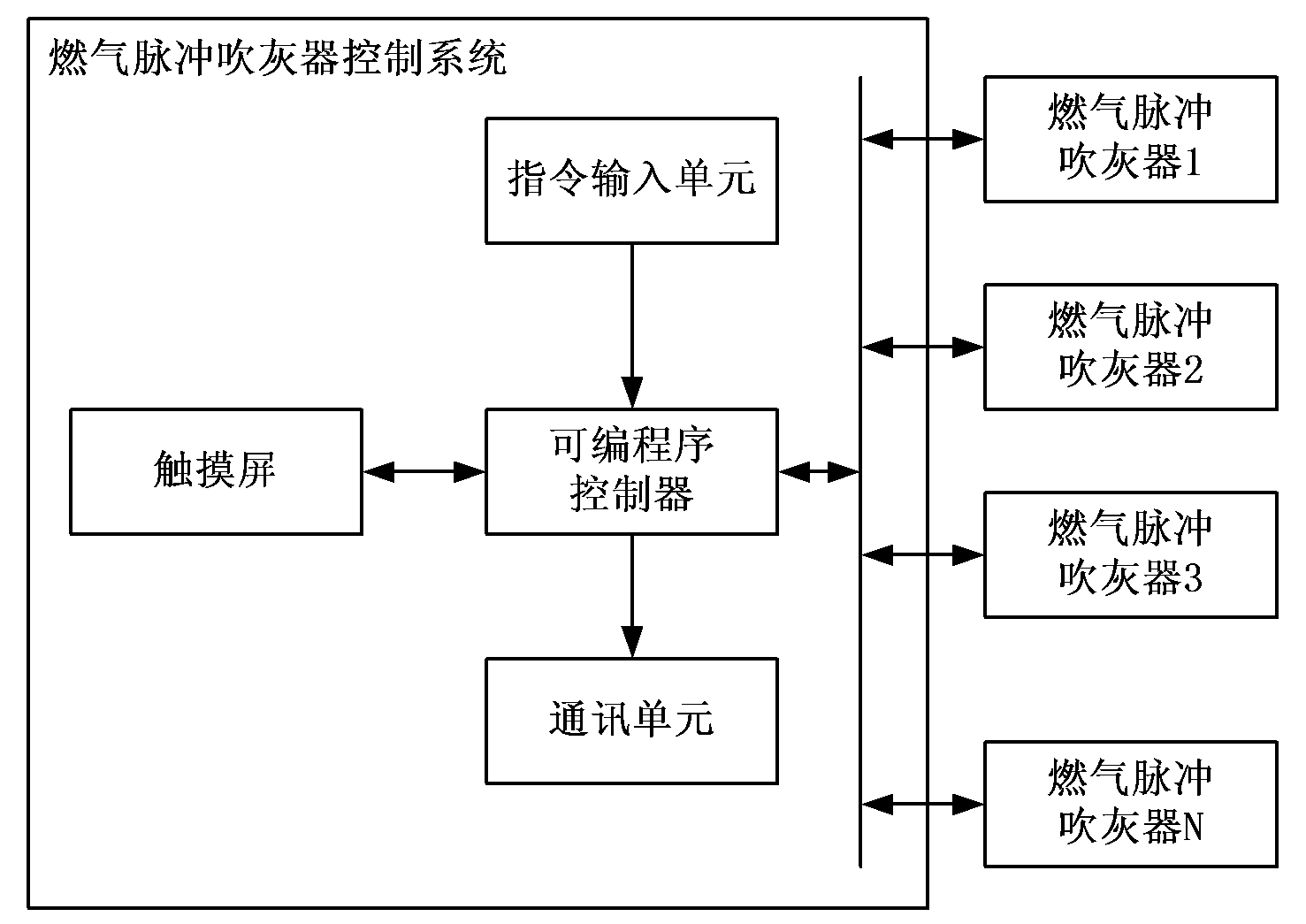

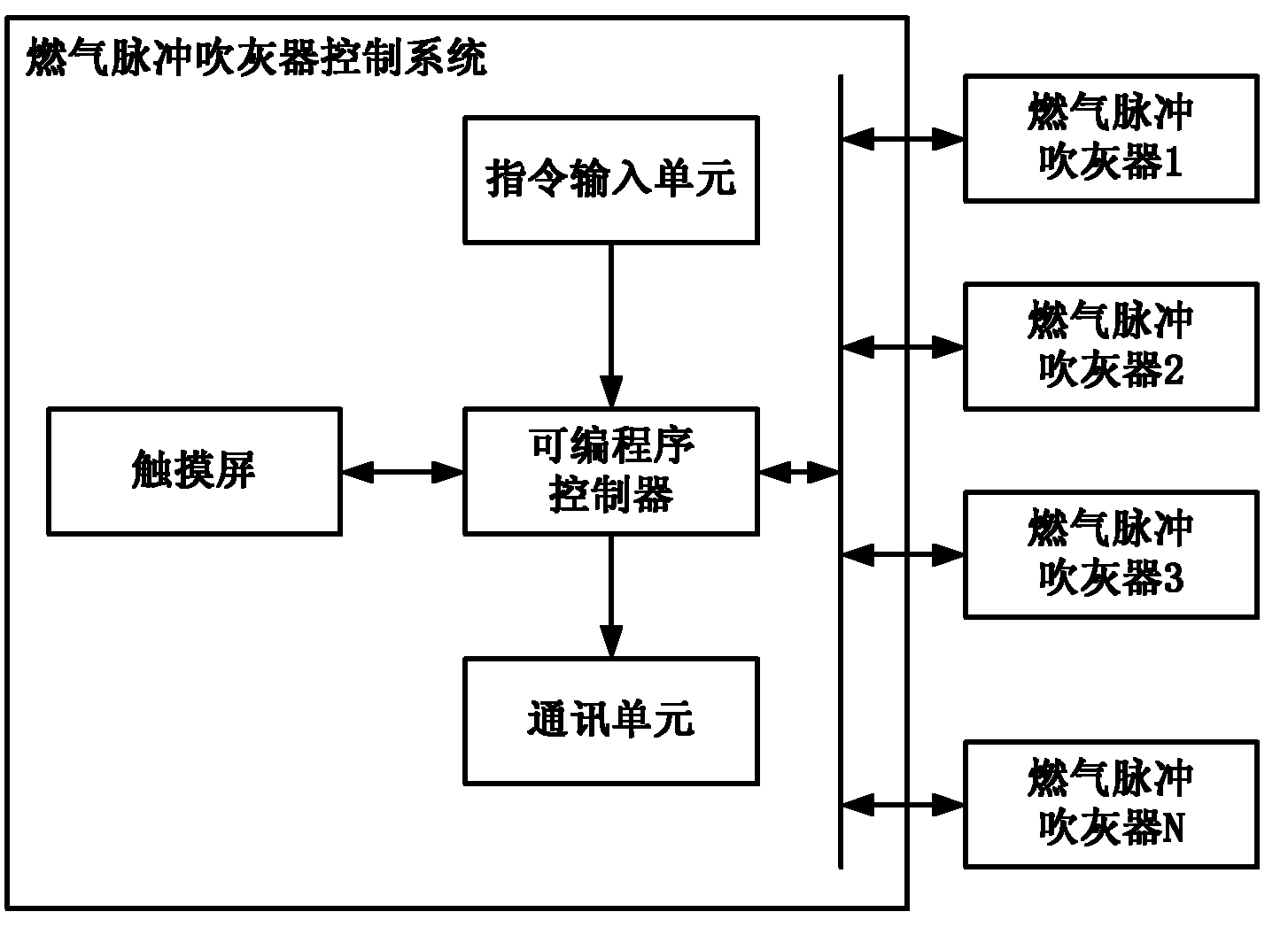

[0025] The operation control system of the gas pulse soot blower according to the present invention is used to control multiple groups of gas pulse soot blowers, such as figure 1 Shown, including: touch screen, programmable controller, and the corresponding connection circuit. Wherein, the programmable controller is connected with each group of gas pulse sootblowers through a connection circuit, and connects each group of gas pulse sootblowers according to external instructions, and receives the operation status information of each group of gas pulse sootblowers . The programmable controller is used as a lower computer to specifically control the operation of the gas pulse sootblower. The programmable controller receives external input instructions and generates different co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com