CCD-based intelligent soot blowing system for formed soot and bonded slag on boiler heating surface

A soot blowing system and heating area technology, applied in the field of intelligent soot blowing system based on CCD boiler heating area ash slagging, can solve problems such as blind soot blowing, unsatisfactory monitoring of ash deposits and slagging in coal-fired boilers, etc., to achieve Large monitoring range, eliminating the influence of environment and emissivity, and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

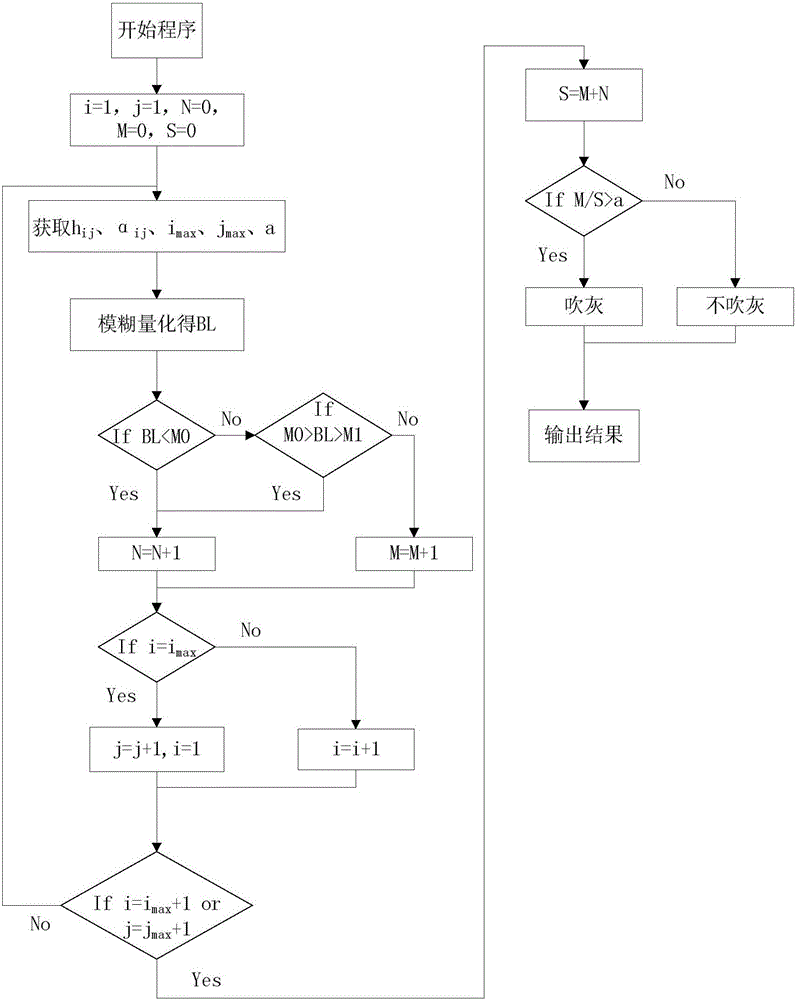

[0029] Below, the invention will be described in detail in conjunction with the accompanying drawings and the specific operation implementation process.

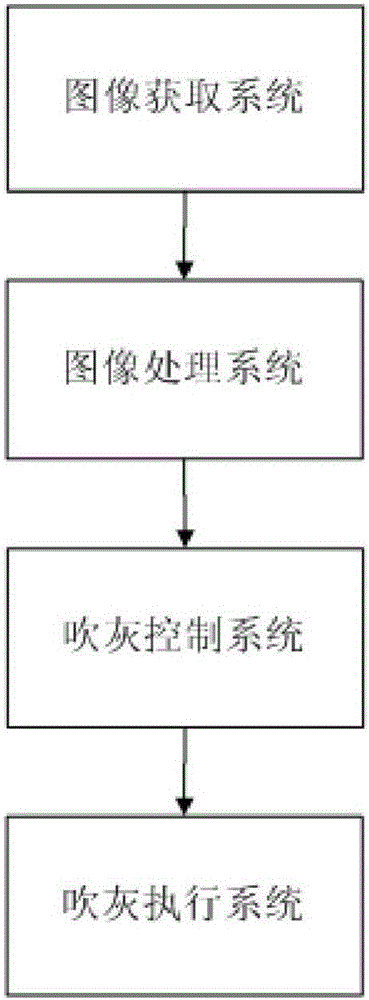

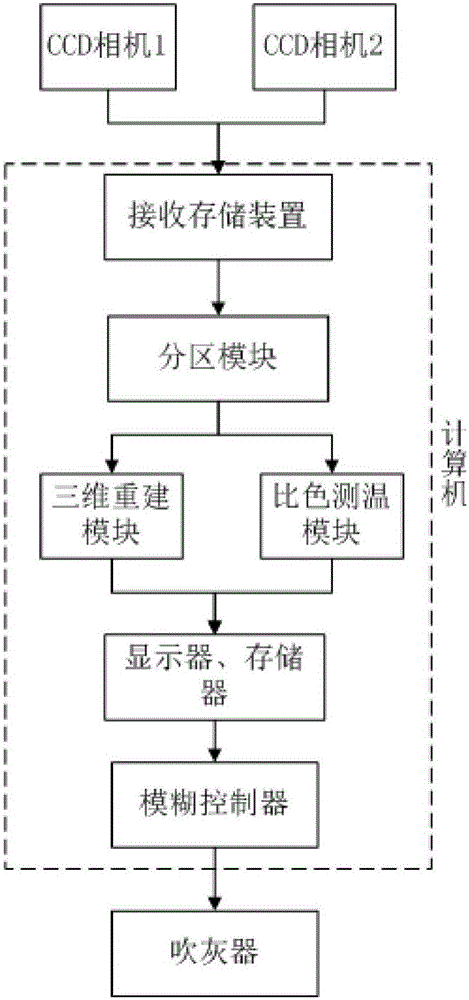

[0030] like figure 1 As shown, a CCD-based intelligent soot blowing system for ash and slagging in the heating area of the boiler includes an image acquisition system, an image processing system, a soot blowing control system, and a soot blowing execution system. The image acquisition system is arranged on the boiler wall, and the obtained two-dimensional The image enters the computer through the receiving storage device and is stored in it. The image processing system obtains the two-dimensional image from the storage place and performs three-dimensional reconstruction and colorimetric temperature measurement to obtain the thickness of the ash layer and the relative temperature of the heating surface. The thickness of the layer and the relative temperature of the heating surface are blurred and instructions are issued, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com