Low temperature continuous denitrification process for coke oven smoke and reactor thereof

A reactor and denitrification technology, applied in gas treatment, chemical instruments and methods, membrane technology, etc., can solve problems such as difficult to meet the needs of coking enterprises, block catalyst pores, reduce denitrification efficiency, etc., to reduce investment costs and floor space , good regeneration effect, and the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

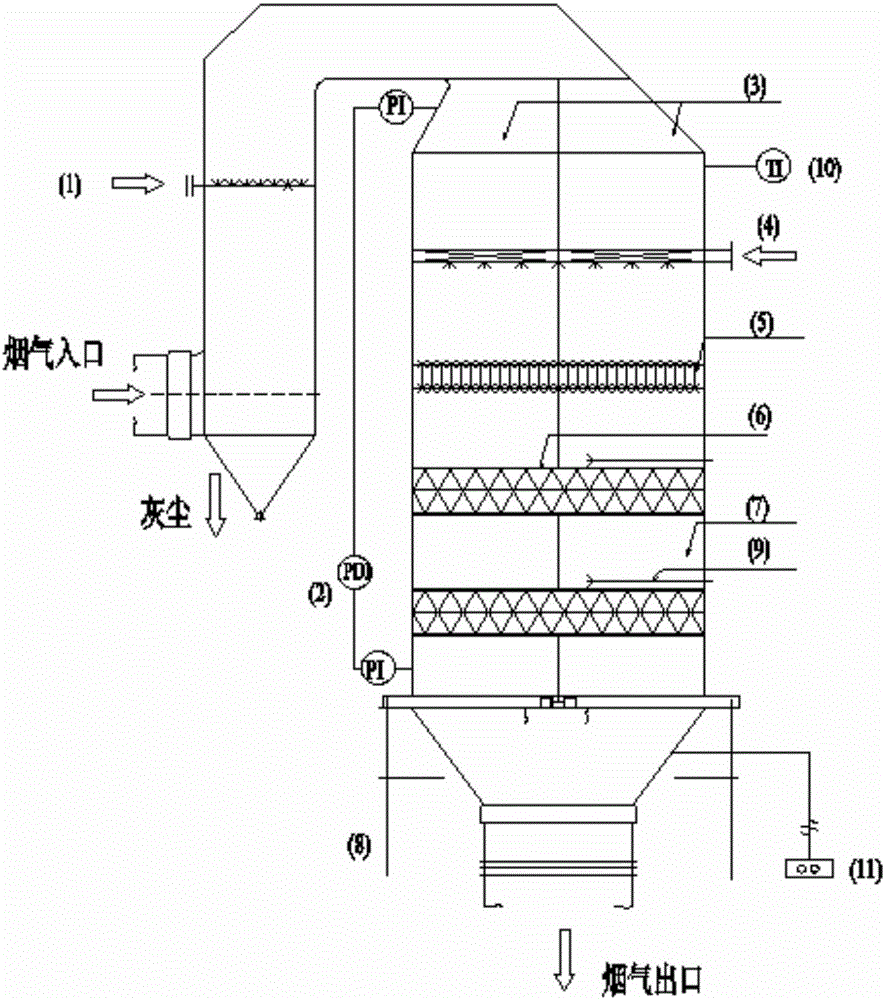

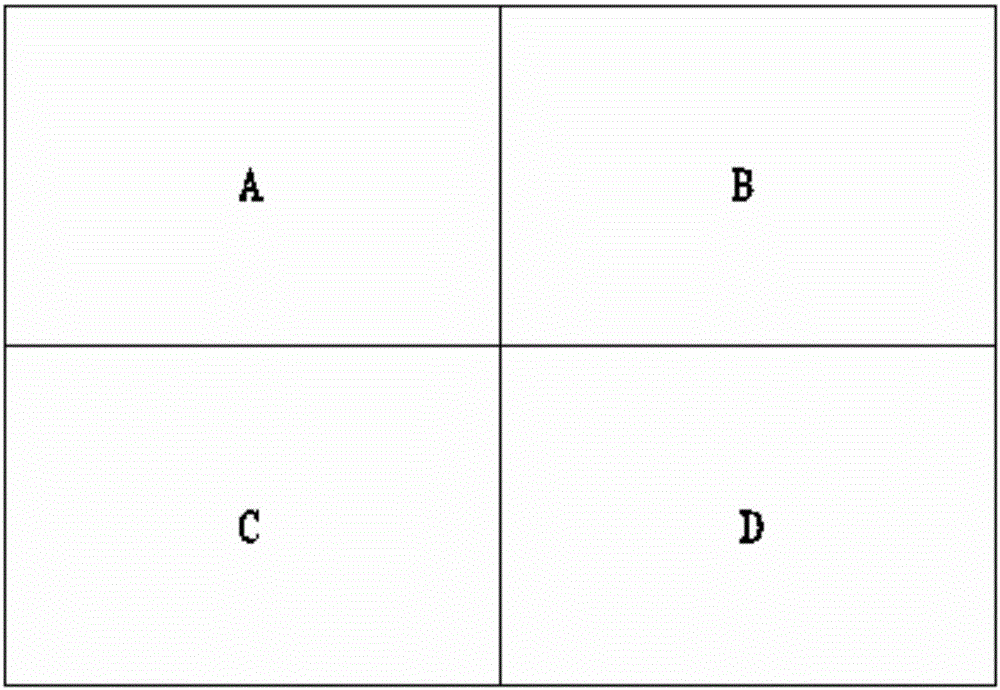

[0035] See attachedfigure 1 and 2 , a low-temperature continuous denitrification reactor for coke oven flue gas is an SCR denitrification reactor, which is divided into four independent areas A, B, C and D. There are insulation facilities between each area, and each area is equipped with an independent Differential pressure transmitter (2), coke oven flue gas inlet pipe valve (3), heat source gas valve (4), rectification grid (5), denitrification catalyst (6), soot blower (9), temperature sensor (10), NH 3 Concentration detector (11). The SCR denitration reactor (7) is placed on the reactor support (8).

[0036] Among them, the denitrification catalyst is a low-temperature sulfur-resistant denitrification catalyst, V 2 o 5 -WO 3 / TiO 2 A series of catalysts, with 3 layers; the pressure difference transmitter (2) is used to monitor the pressure difference between the inlet and outlet of the denitration reactor, which can indirectly reflect the damage caused by the deposit...

Embodiment 2

[0044] See attached figure 1 and 2 , a low-temperature continuous denitrification reactor for coke oven flue gas is an SCR denitrification reactor, which is divided into four independent areas A, B, C and D. There are insulation facilities between each area, and each area is equipped with an independent Differential pressure transmitter (2), coke oven flue gas inlet pipe valve (3), heat source gas valve (4), rectification grid (5), denitrification catalyst (6), soot blower (9), temperature sensor (10), NH 3 Concentration detector (11). The denitration reactor (7) is placed on the reactor support (8).

[0045] Among them, the denitrification catalyst is a low-temperature sulfur-resistant denitrification catalyst, V 2 o 5 -WO 3 / TiO 2 A series of catalysts, with 3 layers; the pressure difference transmitter (2) is used to monitor the pressure difference between the inlet and outlet of the denitration reactor, which can indirectly reflect the damage caused by the depositio...

Embodiment 3

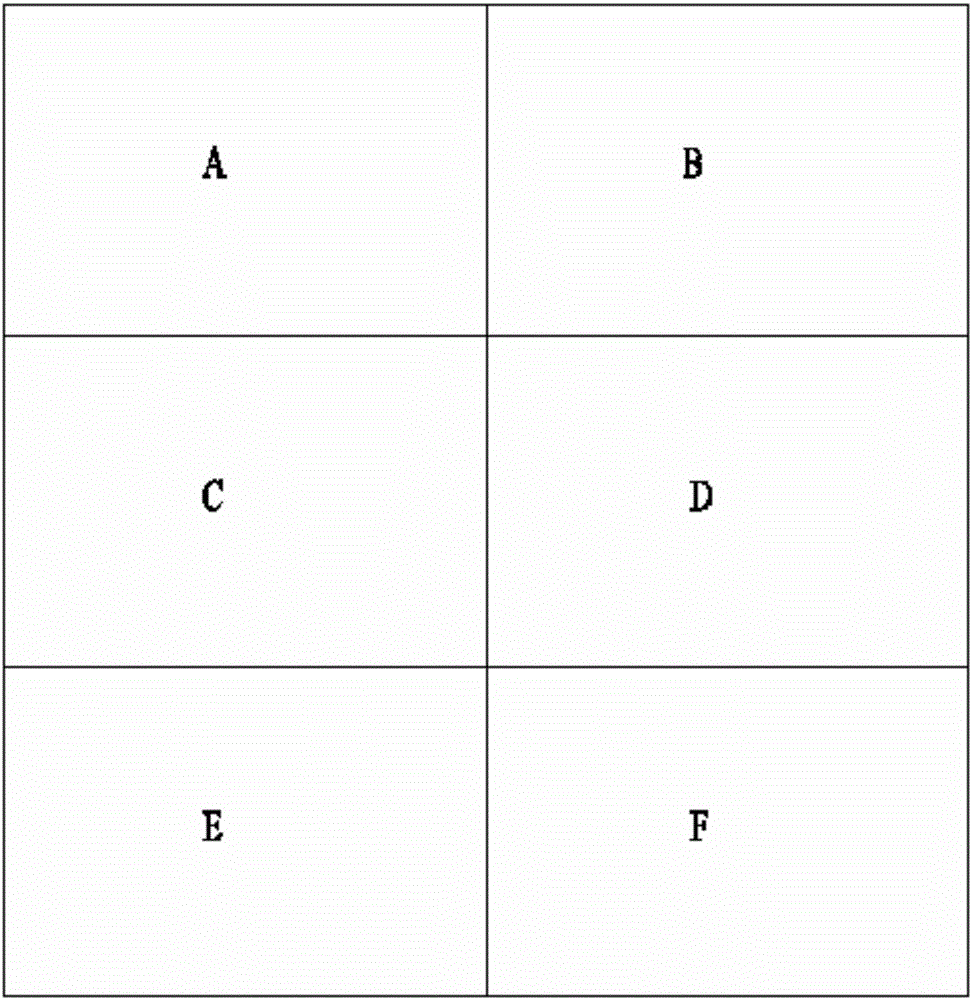

[0054] See attached figure 1 and 3 , a low-temperature continuous denitrification reactor for coke oven flue gas is an SCR denitrification reactor, which is divided into six areas: A, B, C, D, E, and F. Each area is independent of each other. There are insulation facilities between each area. There are independent differential pressure transmitters (2), coke oven flue gas inlet pipe valves (3), heat source gas valves (4), rectification grids (5), denitrification catalysts (6), soot blowers in the area. device (9), temperature sensor (10), NH 3 Concentration detector (11). The denitration reactor (7) is placed on the reactor support (8).

[0055] Among them, the denitrification catalyst is a low-temperature sulfur-resistant denitrification catalyst, V 2 o 5 -WO 3 / TiO 2 A series of catalysts, with 3 layers; the pressure difference transmitter (2) is used to monitor the pressure difference between the inlet and outlet of the denitration reactor, which can indirectly refle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com