Soot-blowing control device and method for boiler furnace based on heat flow online measurement

A boiler furnace and control device technology, applied in control systems, lighting and heating equipment, steam generation, etc., can solve the problems of increased contamination model errors, poor stability and adaptability, and unsatisfactory application effects, saving maintenance. Workload, improve accuracy, reduce boiler failure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

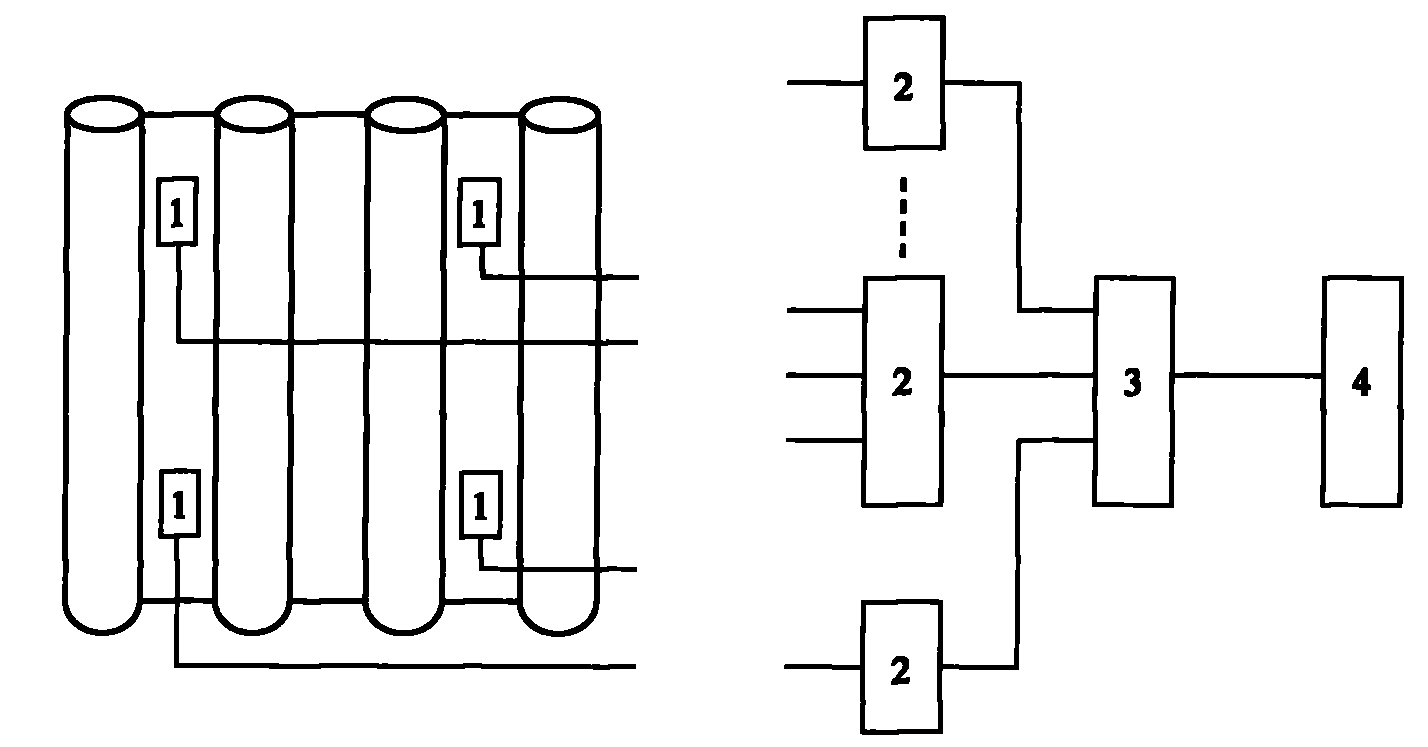

[0027] like figure 1 As shown, the boiler furnace soot blowing control device based on heat flow online measurement according to the present invention includes four parts: heat flow sensor 1 , multiplexer 2 , data collector 3 and industrial computer 4 .

[0028] Select 1 to 4 representative points within the purging radius of each sootblower distributed in the boiler furnace to arrange a heat flow sensor 1 respectively. The monitoring range of the heat flow sensor is preferably a circular surface with a radius of less than 2m. The flow sensors 1 are combined to construct a sensor network for monitoring the contamination of the heating surface of the boiler furnace.

[0029] In this embodiment, the heat flow sensor 1 is a thin-foil heat flow sensor with a circulating water cooling and heat receiving sleeve, which can withstand heat up to 1500°C and can work stably for a long time in the high temperature environment of the boiler furnace. The sensing body of the thermal flow se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com