Method for Online Cleaning of Air Preheaters

a technology of regenerative air heater and online cleaning, which is applied in the direction of cleaning heat-transfer devices, flush cleaning, combustion process, etc., can solve the problems of air and flue gas blocking, reducing heat transfer capacity, and more rapid deterioration of heat exchange elements in the rotor, so as to reduce the accumulation of deposits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

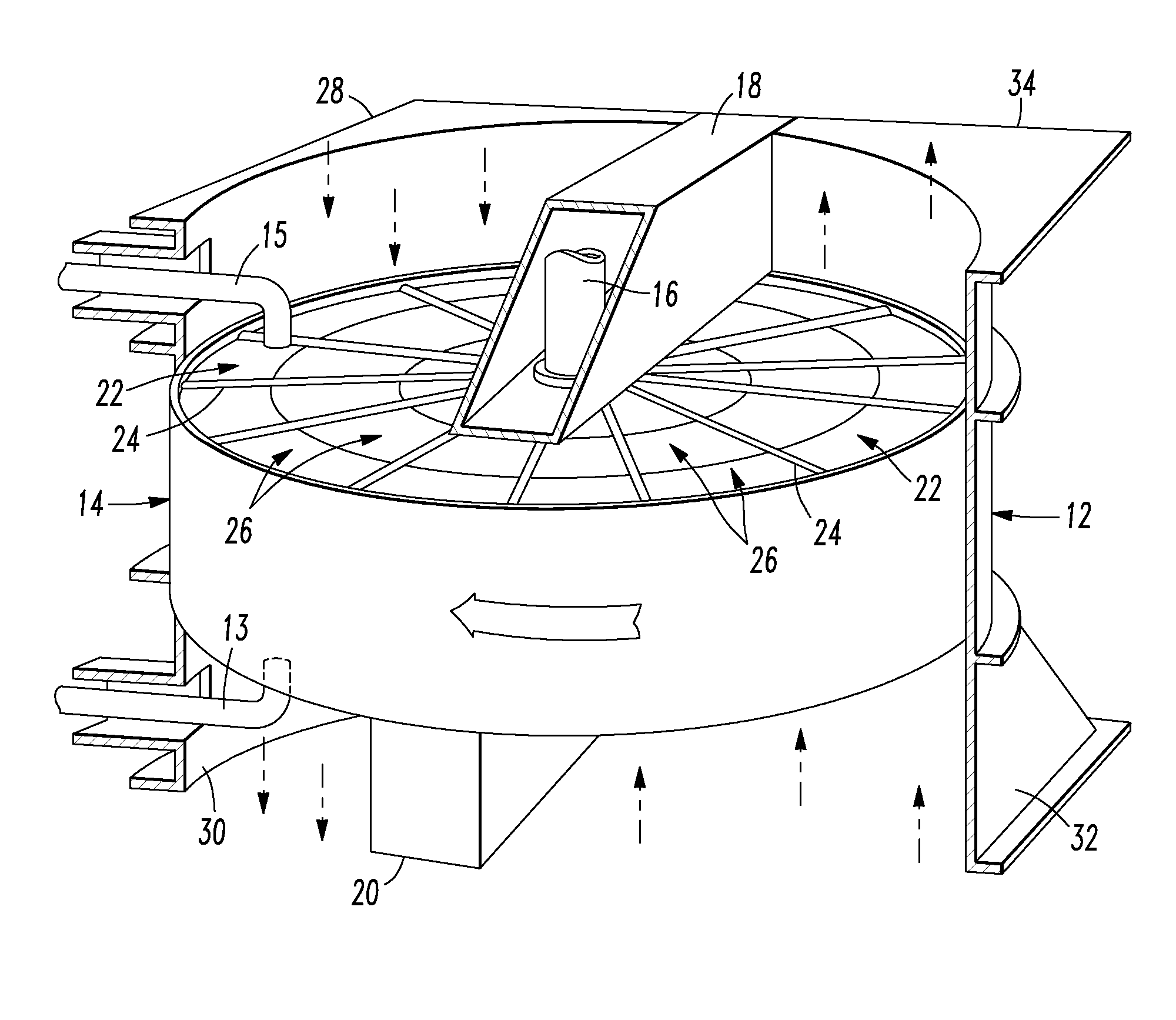

[0022]FIG. 1 is a perspective view of a typical air preheater in which flue gas travels in a vertical, up or down direction and is intended to illustrate one type of air preheater in which the present invention is used. The present invention may be applied to horizontal, vertical (cold end on the top) and vertical inverted (cold end on the bottom) air preheaters. FIG. 1 depicts a vertical air preheater with the cold end on the bottom. The air preheater comprises a rotor housing 12 in which is mounted the heat exchange rotor 14. The rotor is mounted for rotation on the shaft 16 which extends between the upper center section 18 and the lower center section 20. The rotor is divided into sectors or passageways 22 by the diaphragm plates 24 and heat exchange baskets 26 are stacked into these sectors 22. Located at the top and bottom of the air preheater and attached to the rotor housing 12 and to the top and bottom center sections 18 and 20, are the transition duct assemblies identified ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com