Non-circular tunnel boring machine and auxiliary excavation device for tunnel boring machine

A technology of a roadheader and a driving device, which is applied in tunnels, mining equipment, earth-moving drilling, etc., can solve the problems of low excavation efficiency and large blind area of cutter head excavation, so as to improve excavation efficiency, facilitate slag discharge, The effect of increasing the spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

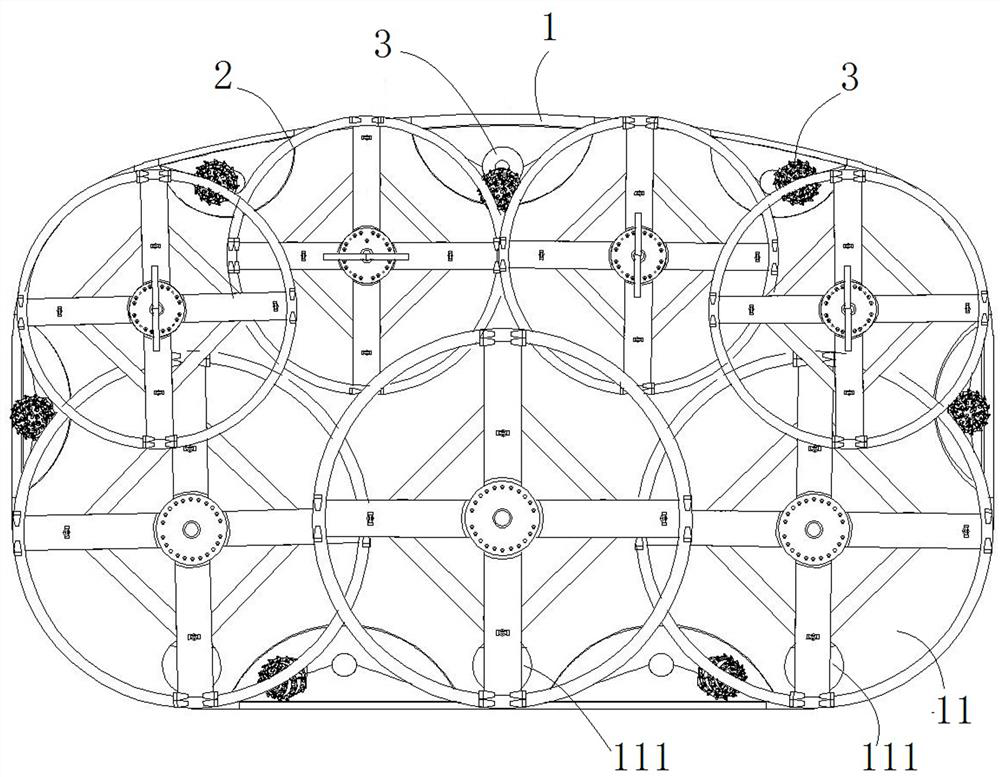

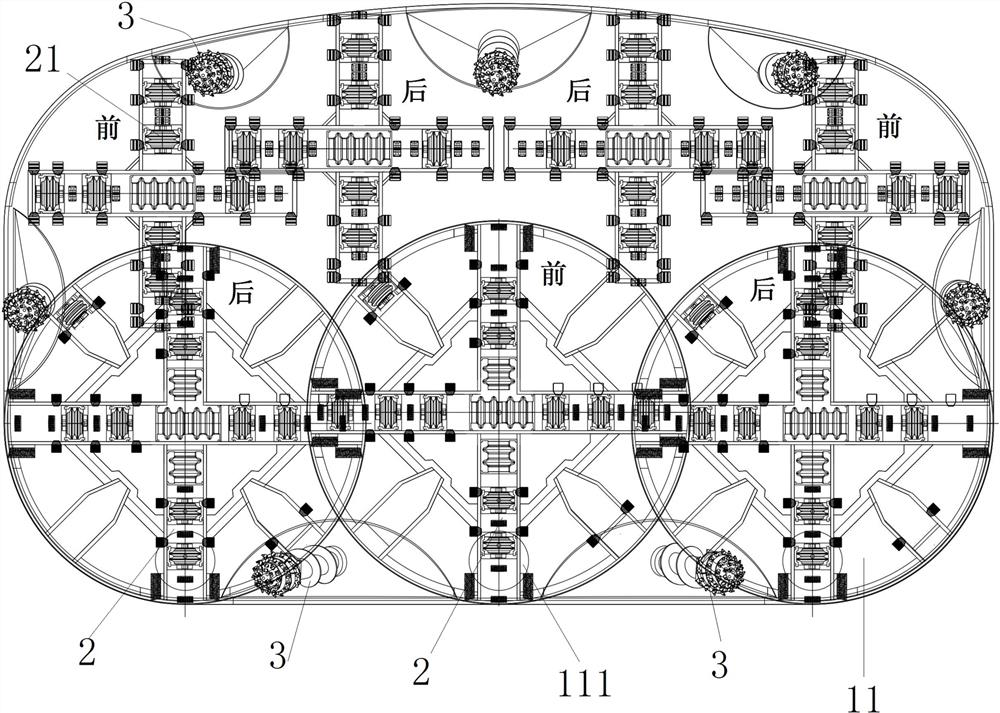

[0136] The non-circular tunnel boring machine of the present invention is applied to the excavation of tunnels with rectangular sections, horseshoe-shaped sections or other special-shaped sections (non-circular sections).

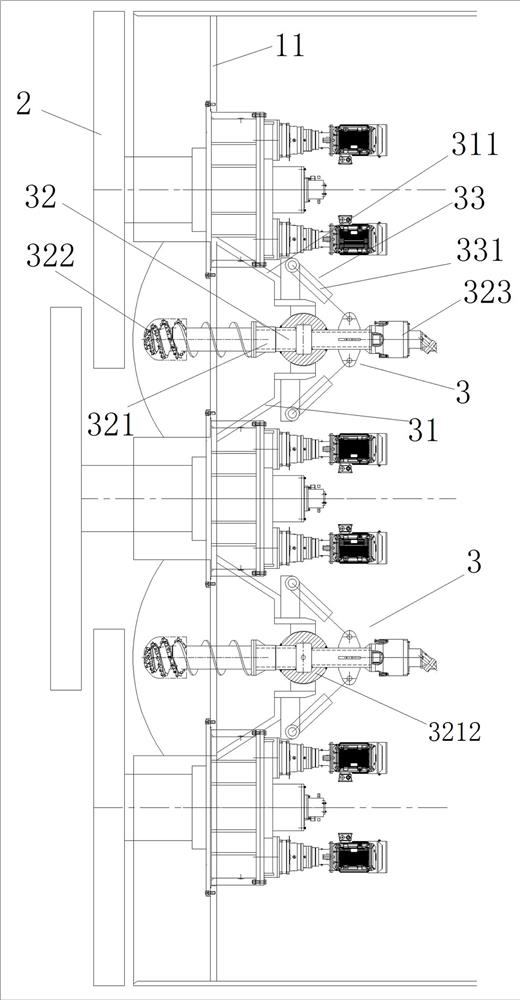

[0137] Such as Figure 1 to Figure 5 As shown, the non-circular tunnel boring machine includes a frame 1, a driving cutter head 2 and an auxiliary excavation device 3 for the roadheader, and the auxiliary excavation device 3 for the roadheader includes a mounting seat 31 installed on the frame 1, a crushing device 32. The adjustment mechanism 33. The frame 1 includes a boring machine partition 11 arranged on the rear side of the boring cutter head 2 . The mounting seat 31 is fixed on the dividing plate 11 of the roadheader.

[0138] The crushing device 32 includes a device base 321 , a crushing head 322 rotatably arranged on the device base 321 , a driving device 323 for driving the crushing head 322 to rotate, and a crushing rod 324 connecting the crushi...

specific Embodiment 2

[0153] Specific embodiment 2 of the non-circular tunnel boring machine of the present invention, the difference between the structure of the non-circular tunnel boring machine in this embodiment and the above-mentioned embodiment is that, as Image 6 As shown, the crushing head 322 is provided with a nozzle 3221 for spraying water, the water inlet channel 3241 communicating with the nozzle 3221 is arranged in the crushing rod 324, the rear end of the crushing rod 324 is provided with a rotary water joint 5, and the internal water channel of the rotary water joint 5 Connected with the water inlet channel, the rotary water joint 5 is arranged between the device base 321 and the breaking rod 324, and the external interface of the rotary water joint protrudes from the device base to connect with the external flexible pipe.

[0154] The specific embodiment 3 of the non-circular tunnel boring machine of the present invention differs from the foregoing embodiments in that, as Figure...

specific Embodiment 6

[0157] The specific embodiment 6 of the non-circular tunnel boring machine of the present invention differs from the above-mentioned embodiments in that, as Figure 10 As shown, in this embodiment, the non-circular tunnel boring machine also includes a crushing drum 6, and the crushing drum 6 is rotatably arranged on the roadheader frame for breaking the excavation blind area of the roadheader. The crushing drum 6 includes a cylinder body 61 and a set With the cutting teeth 62 on the cylinder, the axis of rotation of the crushing drum 6 is perpendicular to the axis of the driving cutter head 2 . The crushing drum 6 is provided with a hydraulic motor, which drives the crushing drum to rotate. In other embodiments, the crushing drum can also be driven by a motor, the axis of the motor extends forward and backward, and the crushing drum is driven by a bevel gear.

[0158] Two crushing drums 6 are provided in this embodiment, instead of the two crushing devices arranged in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com