Single chip microcomputer control based automatic soot cleaning device for soot pipeline

A single-chip microcomputer control and control device technology, applied in the field of pipeline cleaning, can solve the problems of incomplete removal of smoke dirt, low work efficiency, inhalation into the body, etc., and achieve the effect of flexible use range, high work efficiency and enhanced stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

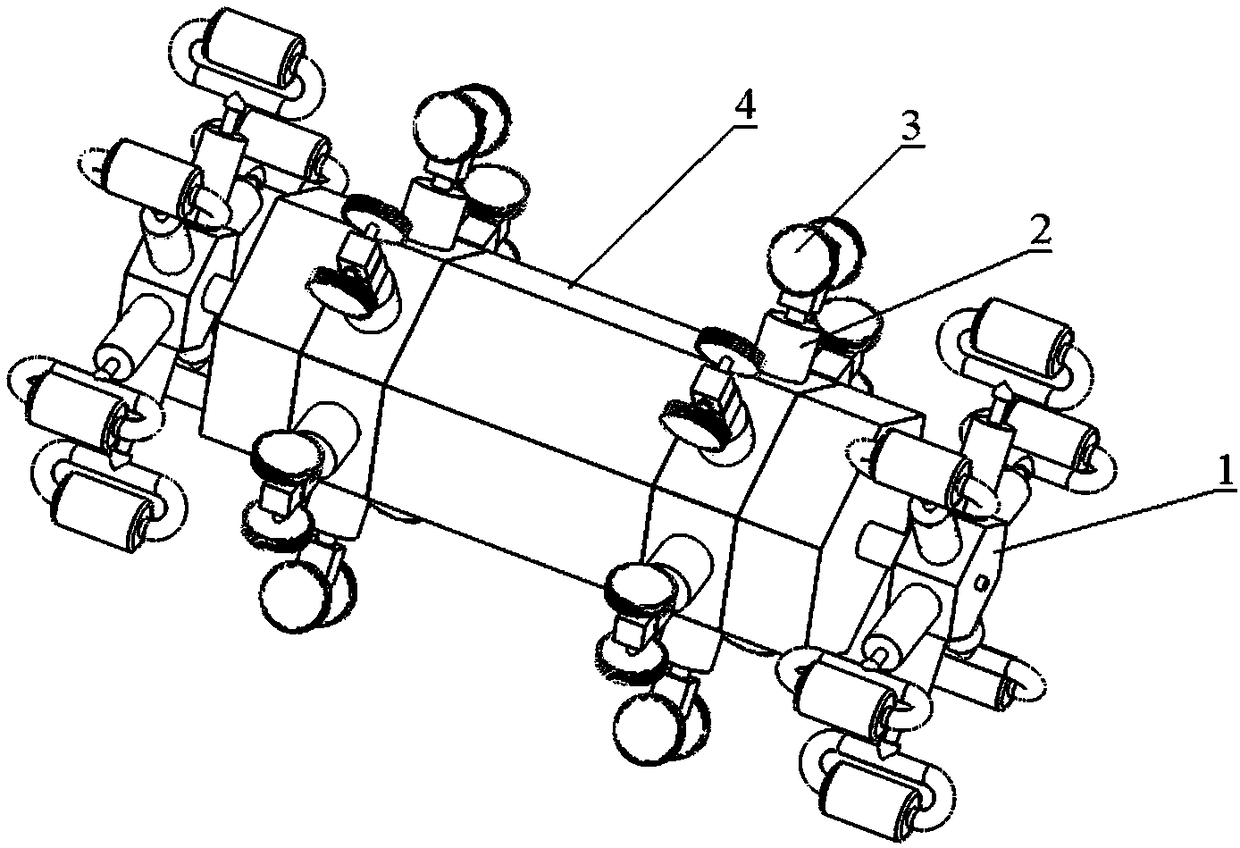

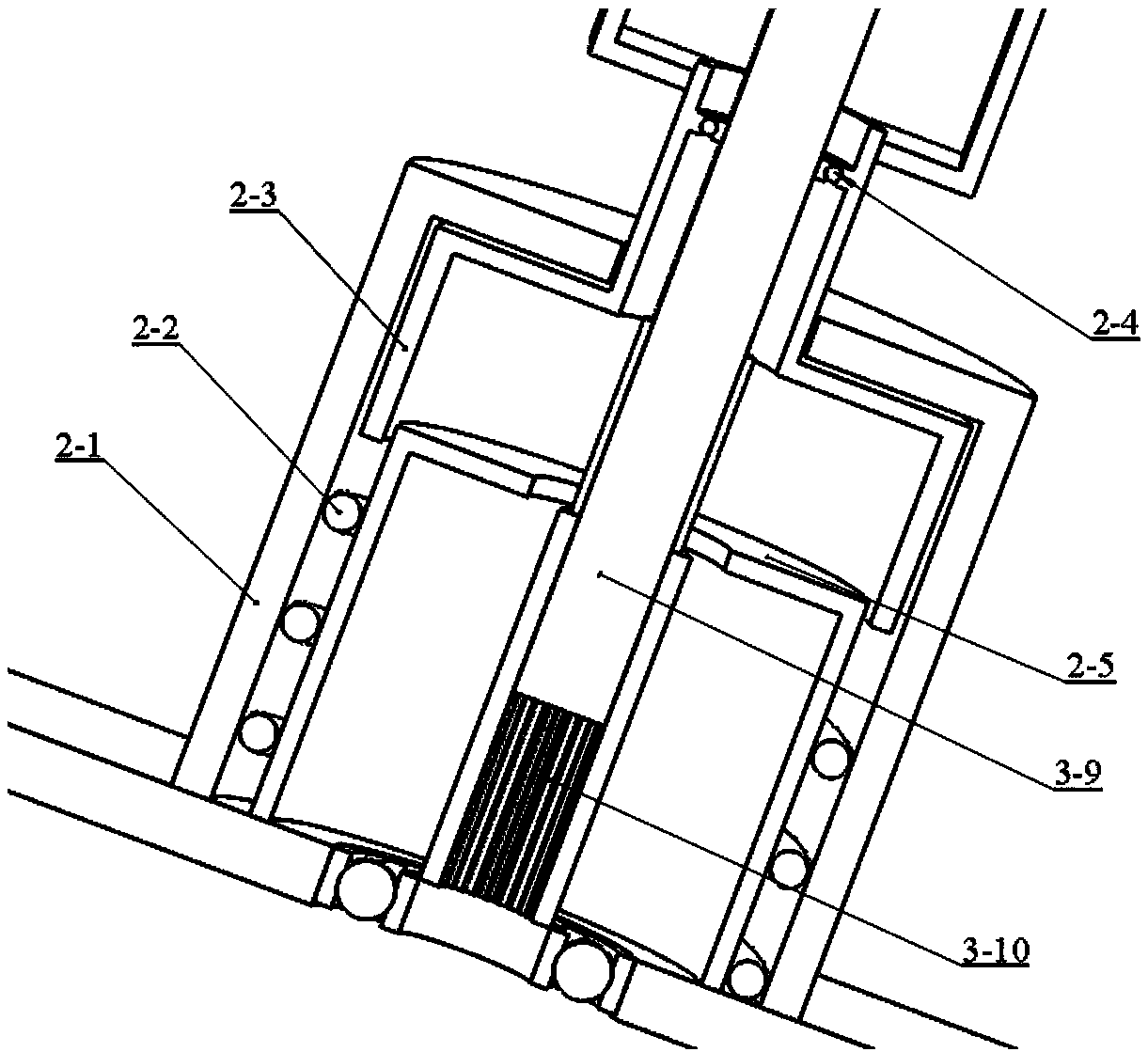

[0029] An automatic ash removal device for soot pipes based on single-chip microcomputer control, such as figure 1 As shown, it includes a cleaning mechanism 1, a telescopic mechanism 2, a traveling mechanism 3 and a housing 4. The above-mentioned module uses the shell 4 as the skeleton, and the dust cleaning mechanism 1 is symmetrically installed at the front and rear ends of the shell 4, and the telescopic mechanism 2 and the walking mechanism 3 are symmetrically installed on the side of the shell 4. Inside the shell 4, there are The control device and the power supply device are provided with a remote control module on the outside of the casing 4, and control the operation of the entire dust cleaning mechanism 1 through a wireless connection.

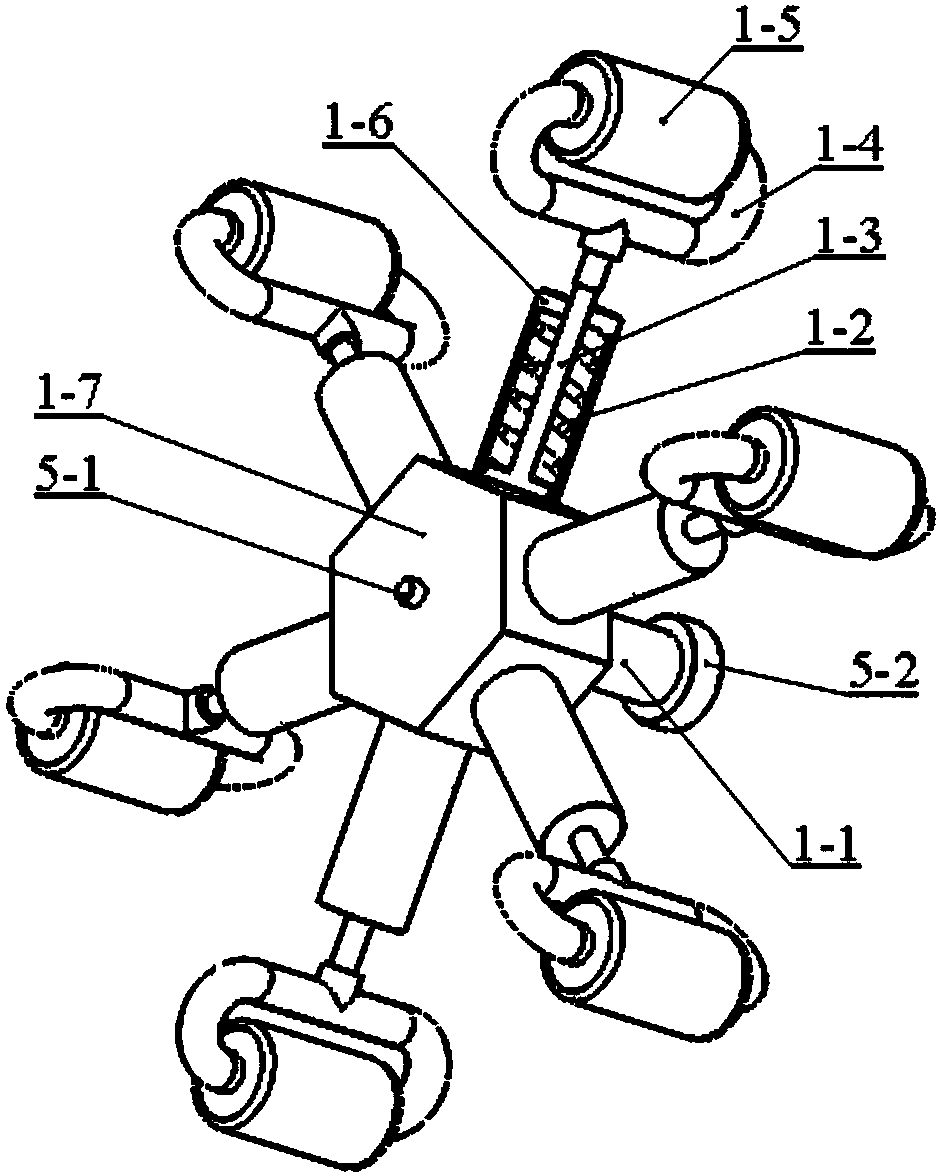

[0030] Such as figure 2As shown, the dust removal mechanism includes a connecting shaft 1-1, a spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com