Movable electric dust removing device achieving filtration through dust collecting electrodes

A dust collecting pole and electrostatic precipitator technology, applied in the direction of electrode cleaning, electrostatic separation, electrostatic effect separation, etc., can solve the problems of reduced and unresolved dust removal efficiency, achieve the effect of improving dust removal efficiency and solving secondary dust raising

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

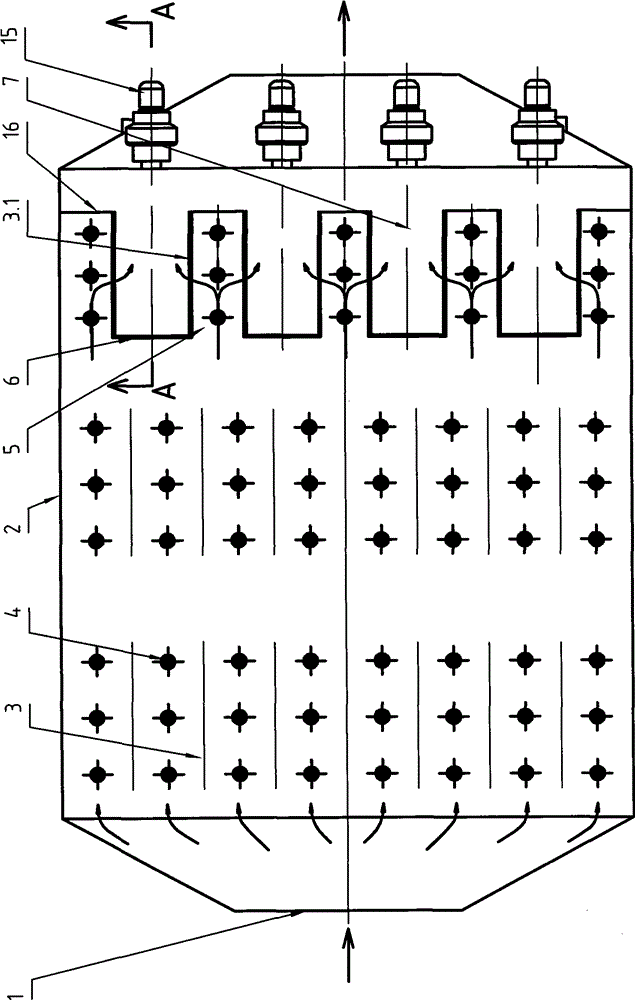

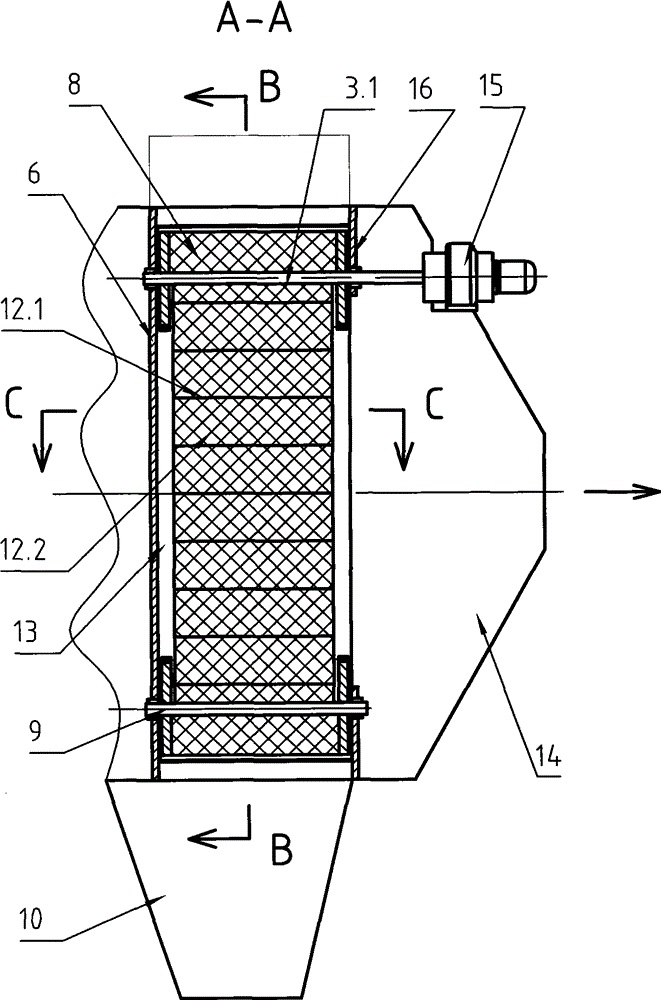

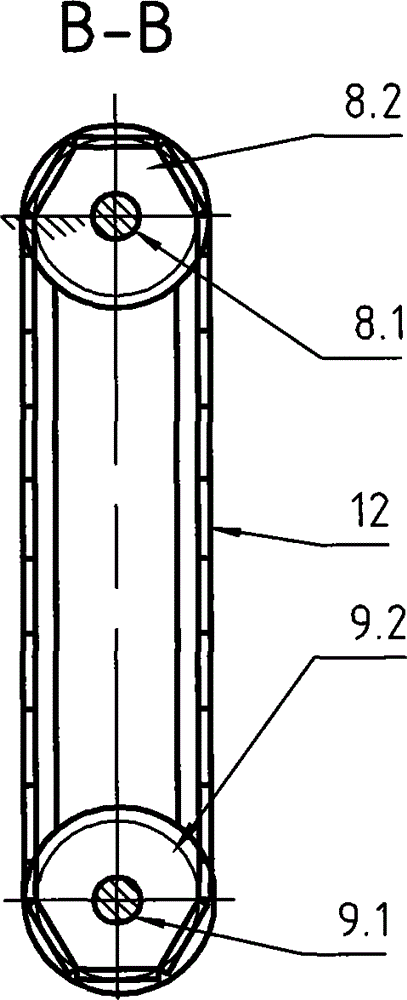

[0043] Example 1, such as Figure 1 to Figure 5 shown.

[0044] The movable dust-collecting pole filter electrostatic precipitator of the present invention includes a gas inlet 1, a housing 2, an anode 3, a cathode 4, a gas outlet 14, an ash hopper 10, a power supply system 11 (not shown), etc., and is characterized in that: The anode 3 constitutes the dust collection pole, and in the direction of the flow of the dust-laden gas, at least a part of the dust collection pole at the rear of the dust collection pole is a mesh dust collection pole 3.1; the net dust collection pole 3.1 is arranged in parallel with the baffles (6, 13, 16) Interconnected to form the air intake space 5 of the mesh dust collector and the air outlet space 7 of the mesh dust collector. 7, flow to the gas outlet 14; the air intake space 5 of the mesh dust collecting pole between the mesh dust collecting poles 3.1 is arranged with the cathode 4; 8 and the filter body 12 etc. of the lower rotating part 9, t...

Embodiment 2

[0053] Example 2, such as Figure 6 ~ Figure 7 shown.

[0054] This embodiment is a change carried out on the basis of Embodiment 1, the difference is:

[0055] 1. In the flow direction of the dusty gas, the dust collection poles are all mesh dust collection poles 3.1.

[0056] 2. Set a brush 19 near the filter body 12 at the lower part of the dust-laden gas mesh dust collection pole 3.1 air intake space 5 to clean the dust on the filter body 12

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com