Winding equipment used for building waterproof films

A technology for building waterproofing and equipment, which is applied in the field of rolling equipment for building waterproof membranes, and can solve the problems of inconvenient replacement of rolls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

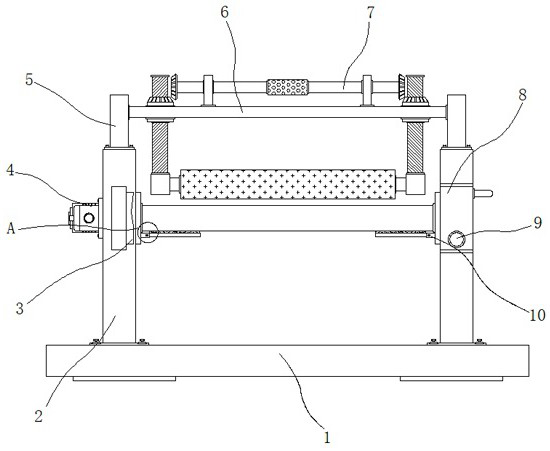

[0026] Example 1: see Figure 1-5 , a kind of winding equipment for building waterproof membrane, including base 1, side plate 2, connecting plate 5 and top plate 6, side plates 2 are fixedly connected to both sides of the top of base 1, and one side of one end of side plate 2 A cleaning structure 3 is arranged between, one end of the top of the side plate 2 is fixedly connected with a connecting plate 5, and one side of the connecting plate 5 is fixedly connected with a top plate 6, the interior of the top plate 6 is provided with a finishing structure 7, and the side plate 2 A winding mechanism is arranged between the inner sides of the

[0027] see Figure 1-5 , a winding device for building waterproof membrane also includes a winding mechanism, the winding mechanism includes a servo motor 4, the servo motor 4 is fixedly connected to the outside of the side plate 2, and the model of the servo motor 4 can be Y2-80M2-4 , the interior of one side of the side plate 2 is provi...

Embodiment 2

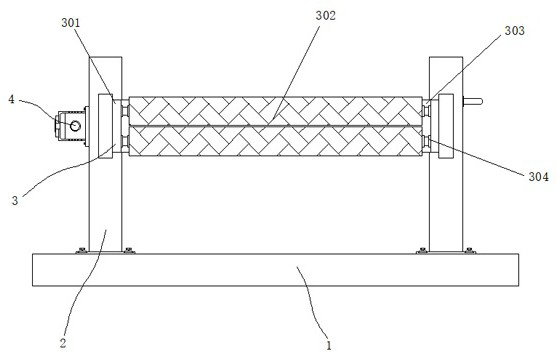

[0029] Embodiment 2: The cleaning structure 3 is composed of a fixed plate 301, a brush cylinder 302, a cavity 303 and a movable shaft 304. The fixed plate 301 is fixedly connected between one end of the side plate 2, and the interior of the fixed plate 301 is provided with a hollow space. A cavity 303, and a movable shaft 304 is movably connected to the top end and the bottom end between the two inner sides of the cavity 303 respectively, and a brush cylinder 302 is movably connected to the outside of the movable shaft 304;

[0030] The brush cylinder 302 is embedded in the interior of the fixing plate 301, and the brush cylinder 302 is symmetrically distributed about the vertical center line of the fixing plate 301;

[0031] Specifically, as figure 1 and figure 2 As shown, the conductive film is inserted through the middle gap of the fixed plate 301, so that the upper and lower ends of the cavity 303 are connected by the movable shaft 304. The brush cylinder 302 cleans the...

Embodiment 3

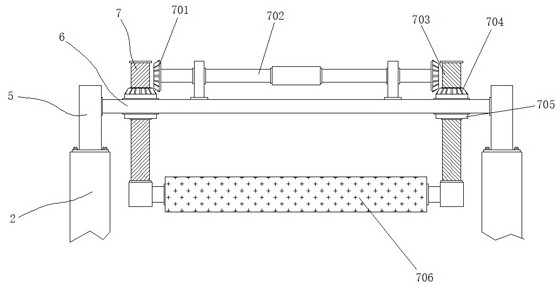

[0032] Embodiment 3: The finishing structure 7 is composed of a transverse gear 701, a rotating shaft 702, a screw 703, a longitudinal gear 704, a threaded sleeve 705 and a roller 706. The threaded sleeves 705 are respectively movably connected on both sides of the interior of the top plate 6, and the threaded sleeves 705 A longitudinal gear 704 is fixedly connected to the top of the threaded sleeve 705, a screw 703 is movably connected to the inside of the threaded sleeve 705, and a roller 706 is movably connected between one side of the bottom end of the screw 703. The rotating shaft 702 is movably connected between the two sides of the top of the top plate 6, Both sides of the rotating shaft 702 are respectively fixedly connected with transverse gears 701;

[0033] The transverse gears 701 are respectively arranged on one side of the top end of the longitudinal gears 704, and the transverse gears 701 and the longitudinal gears 704 are in the same vertical plane;

[0034] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com