Mine dry dust removal device

A dry dust removal and mining technology, applied in the separation of dispersed particles, chemical instruments and methods, and dispersed particle filtration, etc., can solve the problems of entering the lower respiratory tract and depositing in the alveoli, low efficiency of underground dust removal equipment, etc. High security and safety, reduced hazards, and efficient treatment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

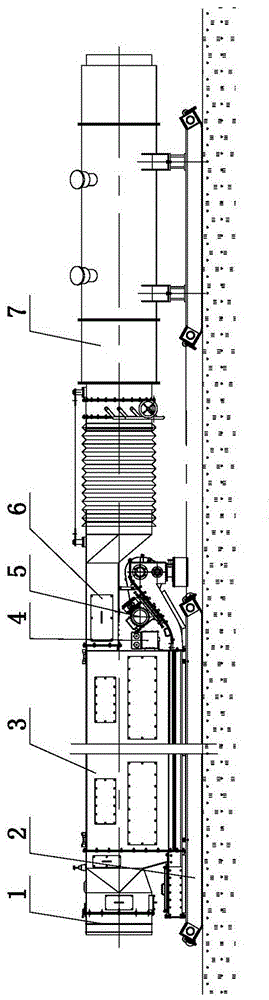

[0038] The present invention includes a base 2, which is characterized in that: a filter box 3 is arranged above the base 2, an ash delivery tank 51 is provided at the inner bottom of the filter box 3, an ash delivery mechanism 5 is arranged on the base 2 corresponding to the ash delivery tank 51, and the filter box 3 The tail end is provided with an air outlet 6; the air outlet 6 is connected with the fan 7 on the base 2.

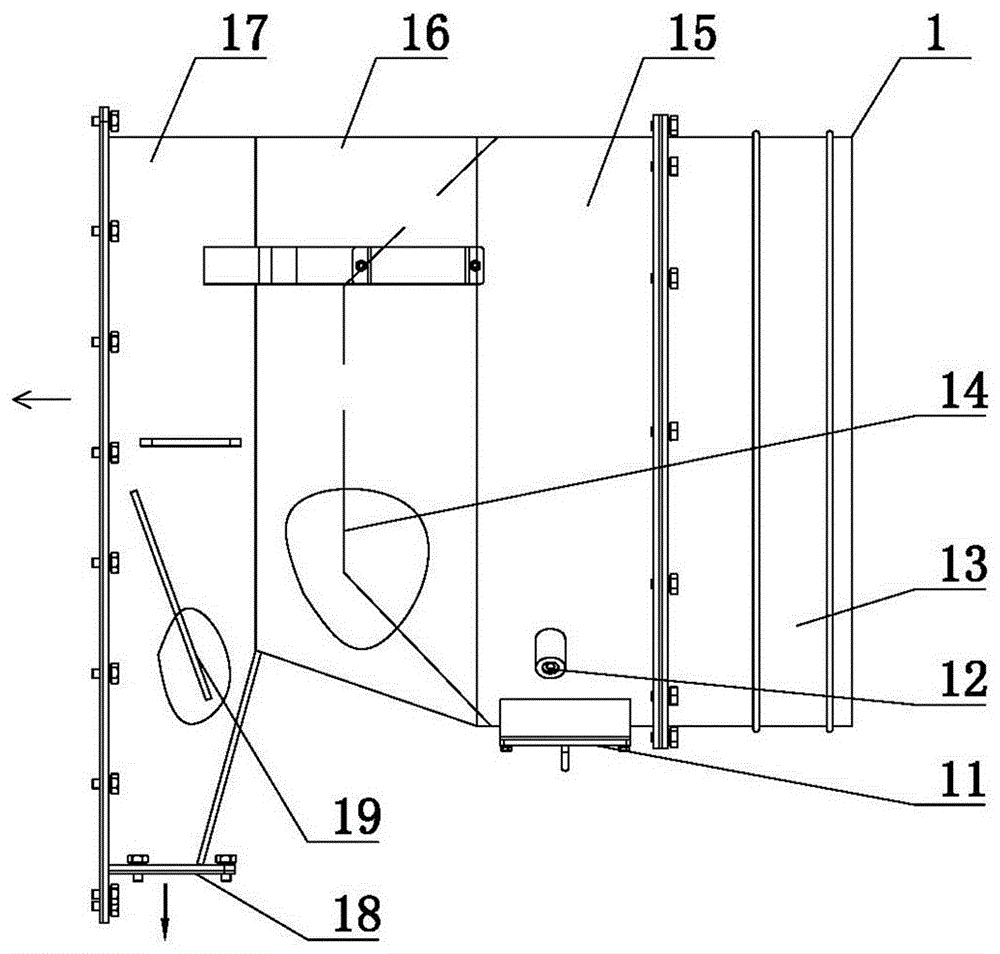

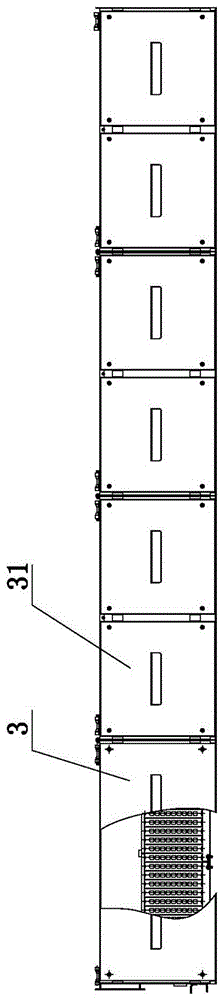

[0039] As a preferred solution of the present invention, the filter box 3 includes a box body 31, and the box body 31 is formed by connecting dust removal box units 32 in series. The dust removal box unit 32 includes a housing 39, and the inner upper end of the housing 39 is A wedge-shaped box 33 is provided, and the side of the wedge-shaped box 33 communicates with the filter chamber 37 at the bottom of the housing 39. A filter element 38 is arranged in the filter chamber 37, and the outlet of the filter element 38 communicates with the clean air box 36 in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com