Hindering collision type pulse-jet dust removal filter cartridge dust removal device

A dust removal device and filter cartridge technology, which is applied in transportation and packaging, dispersed particle filtration, gas treatment, etc., can solve the problems of hindering collision pulse spray and poor dust cleaning, and achieve the effect of good automation performance and simple structure of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

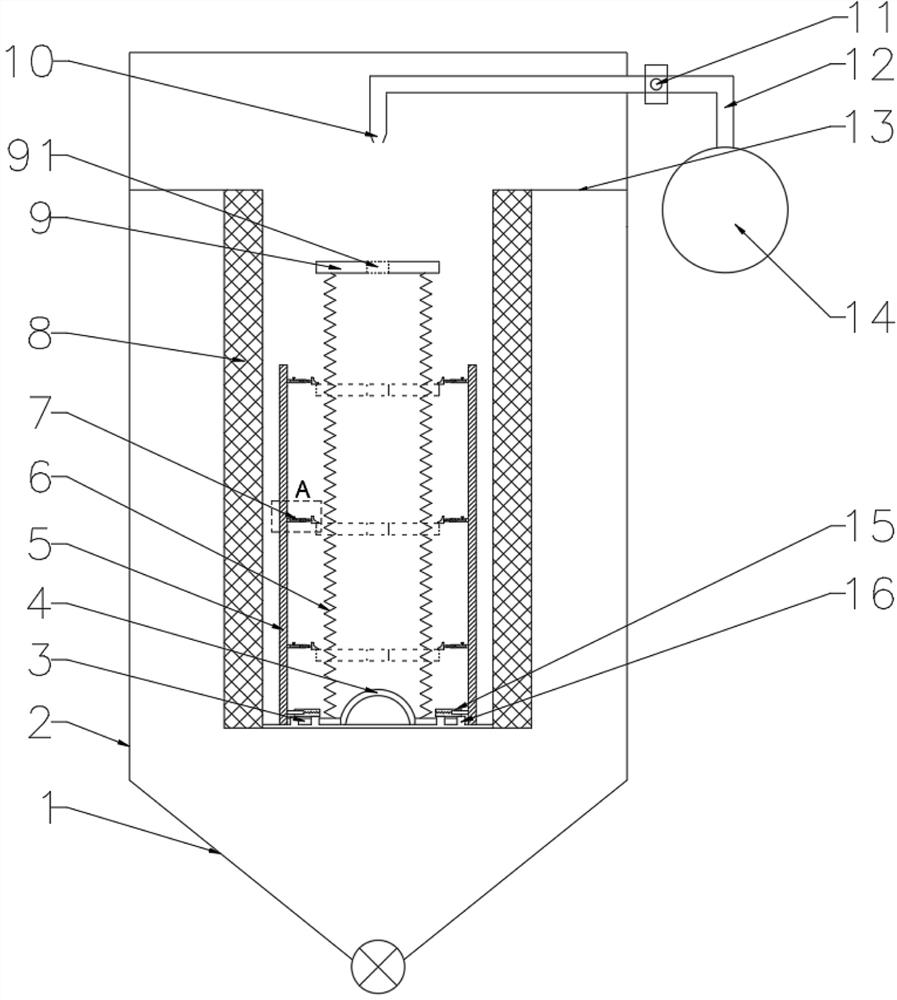

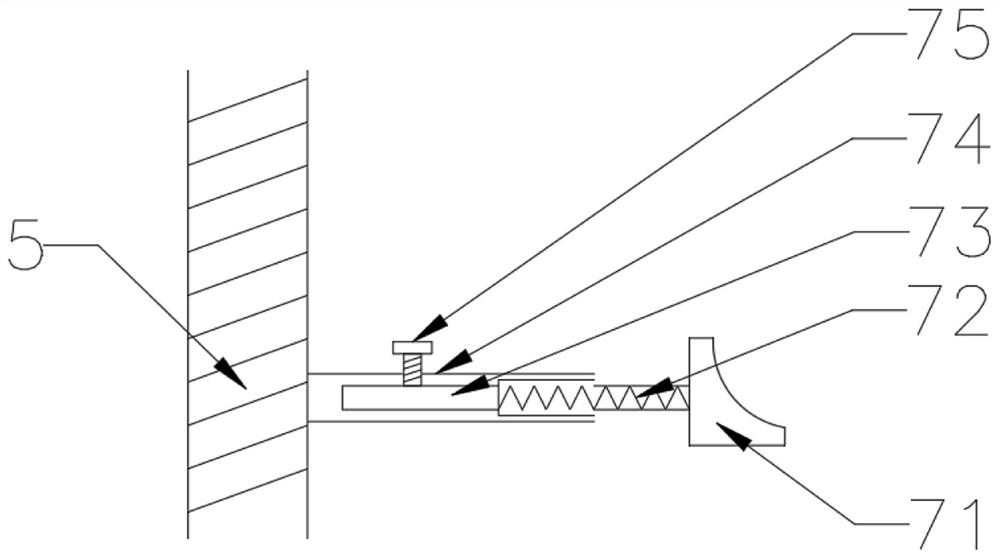

[0021] The invention discloses an impeding collision type pulse jet dust removal filter cartridge dust removal device, which comprises an ash hopper 1, a box body 2, a slide plate 3, an elastic reset plate 4, a bracket 5, a spring I6, a buckle 7, a filter cartridge 8, an impactor Plate 9, nozzle 10, electromagnetic pulse valve 11, spray pipe 12, flower plate 13, air bag 14, damper 15, slideway 16.

[0022] The dust collector box 2 is divided into two parts by the flower plate 13, the upper clean air chamber and the lower filter chamber. The filter chamber is provided with an air inlet, and the clean air chamber is provided with an air outlet. Suspension installs filter cartridge 8, and filter cartridge 8 is the cylindrical structure that bottom end is closed, and upper end is provided with opening.

[0023] A nozzle 10 is provided directly above the opening of the filter cartridge 8, and the nozzle 10 is connected to an air bag 14 through a blowing pipe 12. The blowing pipe 12...

Embodiment 2

[0028] When the dust collector needs to clean dust, it sends a starting signal to the electromagnetic pulse valve 11, and the compressed gas arrives at the nozzle 10 from the air bag 14 through the blowing pipe 12 and the electromagnetic pulse valve 11 and is sprayed out to form a dust-cleaning air flow for the first time. Pulse jet. The blowing air flow in the vertical direction of the filter cartridge 8 collides violently with the impact plate 9, and the dynamic pressure in the axial direction of the air flow is converted into static pressure, and the static pressure exerts pressure on the side wall area of the filter cartridge 8 near the position of the impact plate 9 And realize the cleaning that concentrates here. In this embodiment, the radius of the small hole 91 is 1 / 5 of the radius of the impact plate 9 , so that part of the pulse jet passes through the small hole 91 to reach the space below the impact plate 9 . On the one hand, it can be avoided that: a large amou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com