Auxiliary bracket

A bracket and body technology, which is applied in the field of auxiliary brackets, can solve the problems of being difficult to meet, interfere with each other, a single adjustment mechanism or a lifting mechanism, etc., and achieve the effects of compact structure, convenient adjustment and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

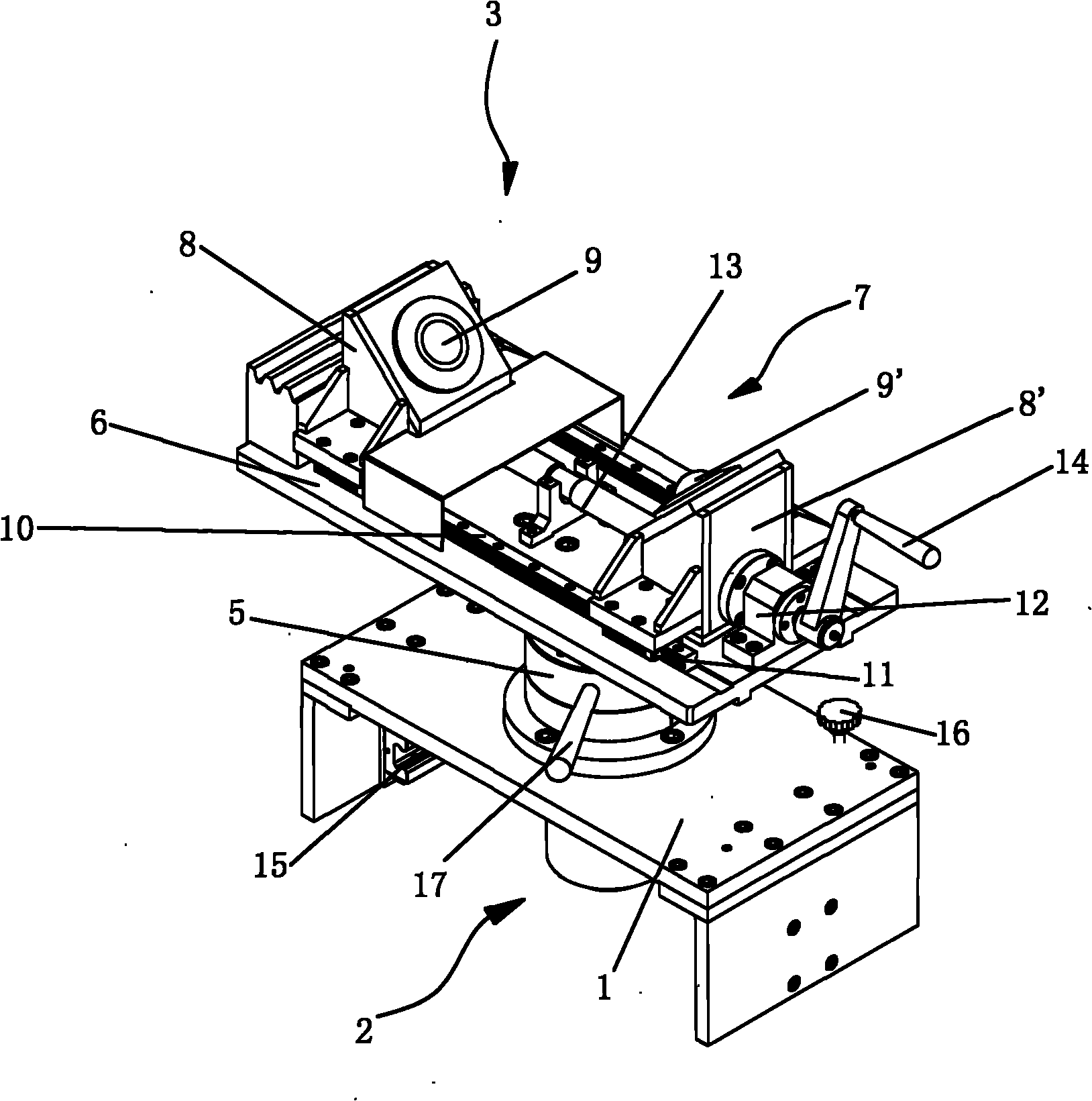

[0021] See attached figure 1 , 2 The auxiliary bracket shown in .

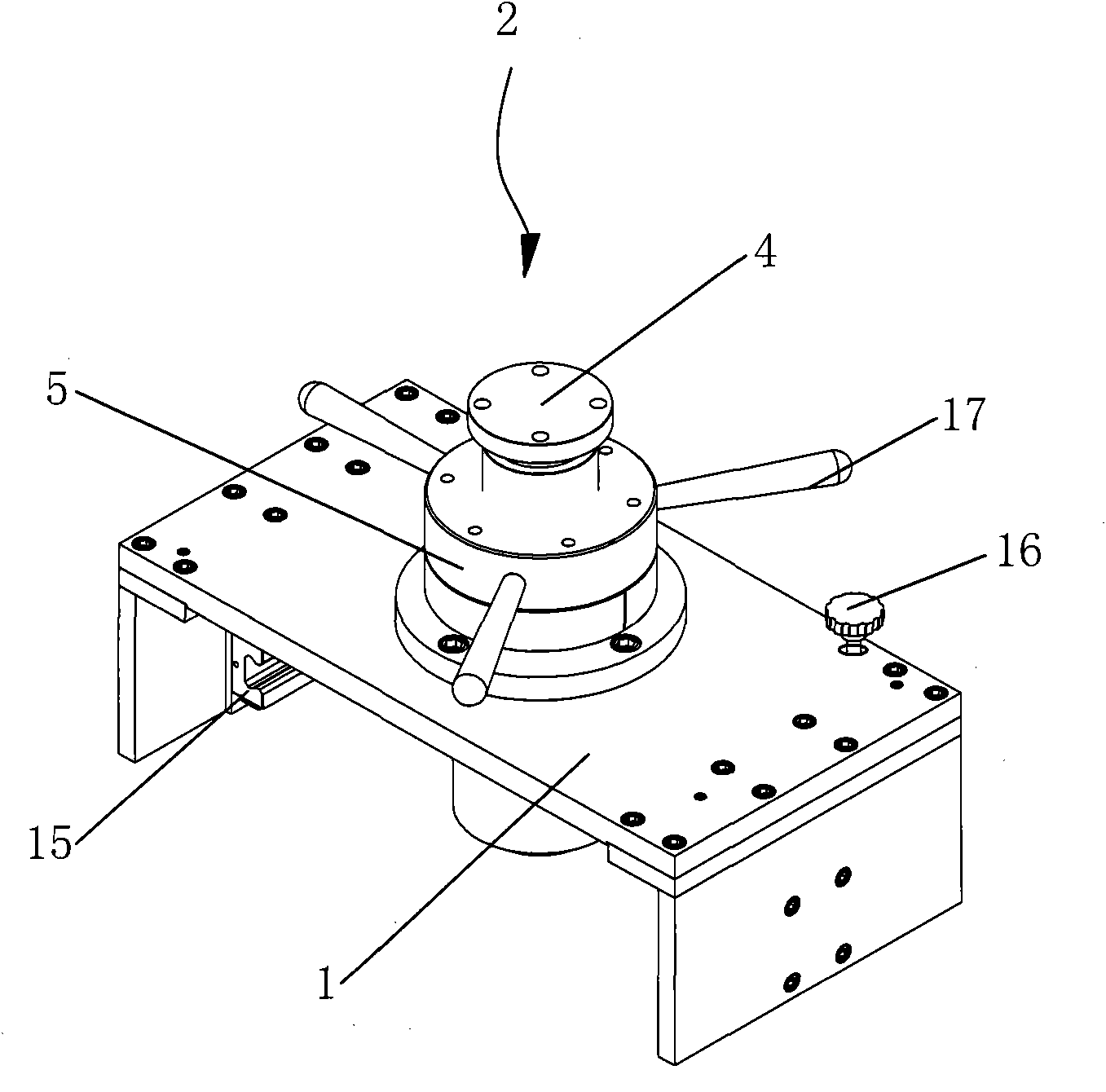

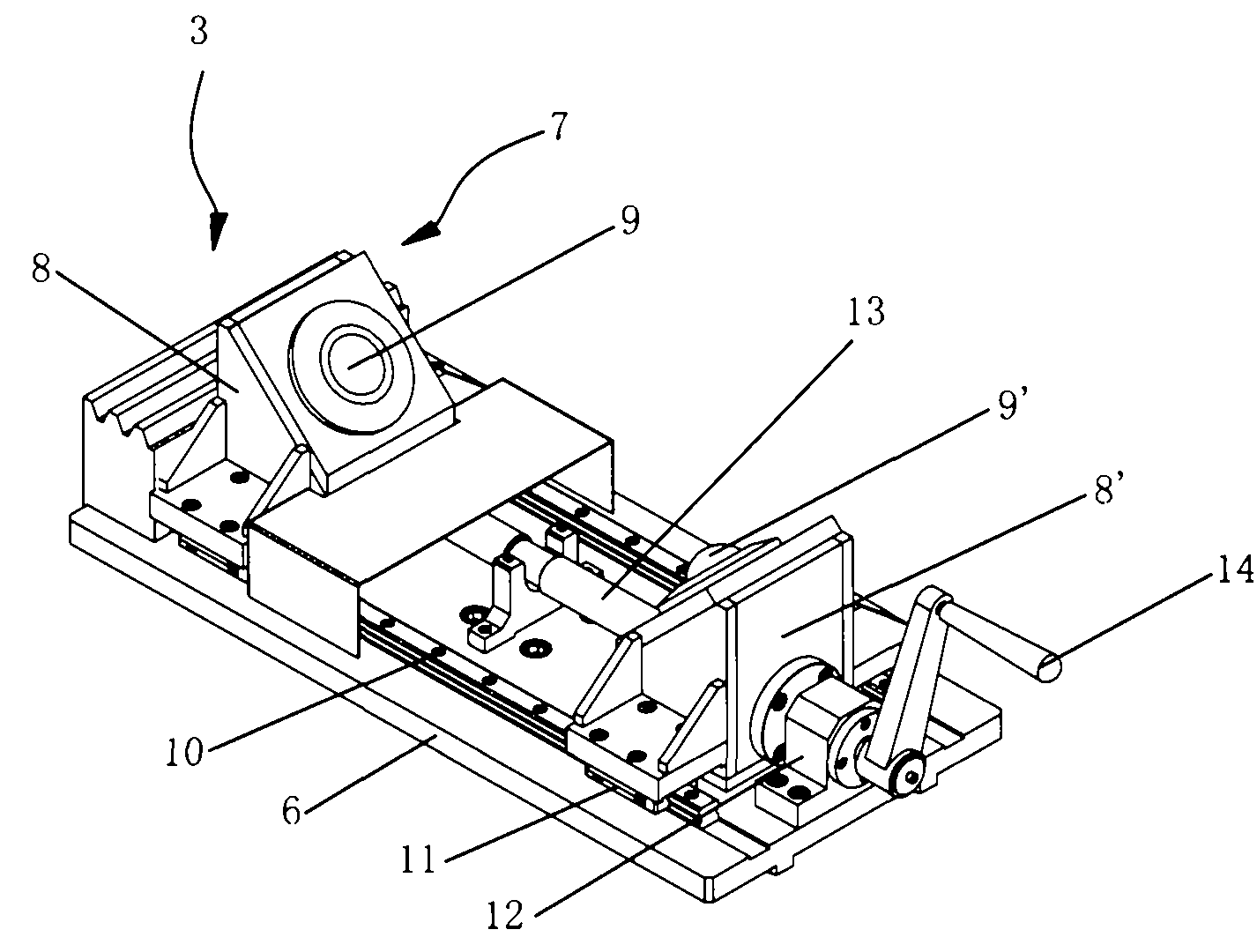

[0022] As shown in the figure, the lifting mechanism 2 includes a lifting screw 4 arranged on the bracket body 1 and a nut 5 threaded on the lifting screw 4. When the nut 5 is rotated, the lifting screw 4 moves up and down. The adjustment mechanism 3 includes a base 6 fixedly installed on the top of the screw, and a clamping unit 7 arranged on the upper surface of the base 6. The clamping unit 7 includes a pair of universal ball brackets 8 that can move relatively on the base 6 and 8', universal balls 9 are installed on each universal ball bracket 8, and the workpiece can be clamped between a pair of universal balls 9 and 9'. A second handle 17 is fixedly installed on the nut 5 .

[0023] In order to enable a pair of universal ball brackets 8 and 8' to move relatively, front and rear line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com