Cable and pin tube cavity contact pair as well as apparatus and method for brazing cable connector

A technology of cable joints and cables, which is applied in the direction of circuits, connections, electrical components, etc., can solve the problems of excessive oxidation of weldments, deterioration of substrate quality, and weak welding, etc., and achieve high processing efficiency, simple operation, and easy quality assurance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Specific embodiments of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

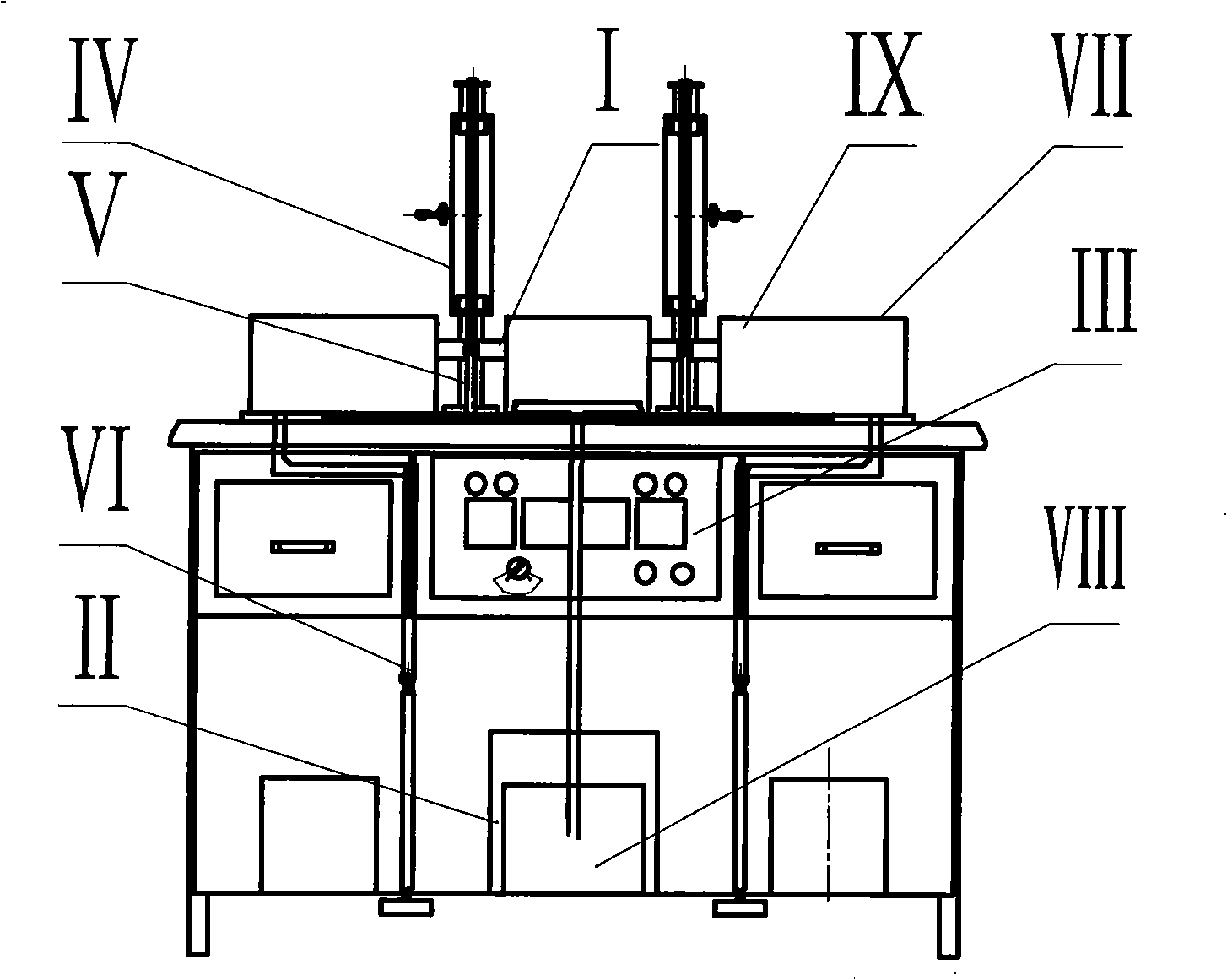

[0033] A brazing device for a cable wire and a pin lumen contact pair and a cable joint of the present invention is controlled by a pair of graphite or graphitized electrodes I for elastically clamping the base of the weldment, a transformer device II, and manual or electrical switching System III, adjustable cable clamping mechanism IV, weldment substrate positioning and holding block V, pedal lever clamping mechanism VI, safety shield VII, air-cooled or water-cooled device VIII, and single-station or double-station workbench IX composition, such as figure 1 shown.

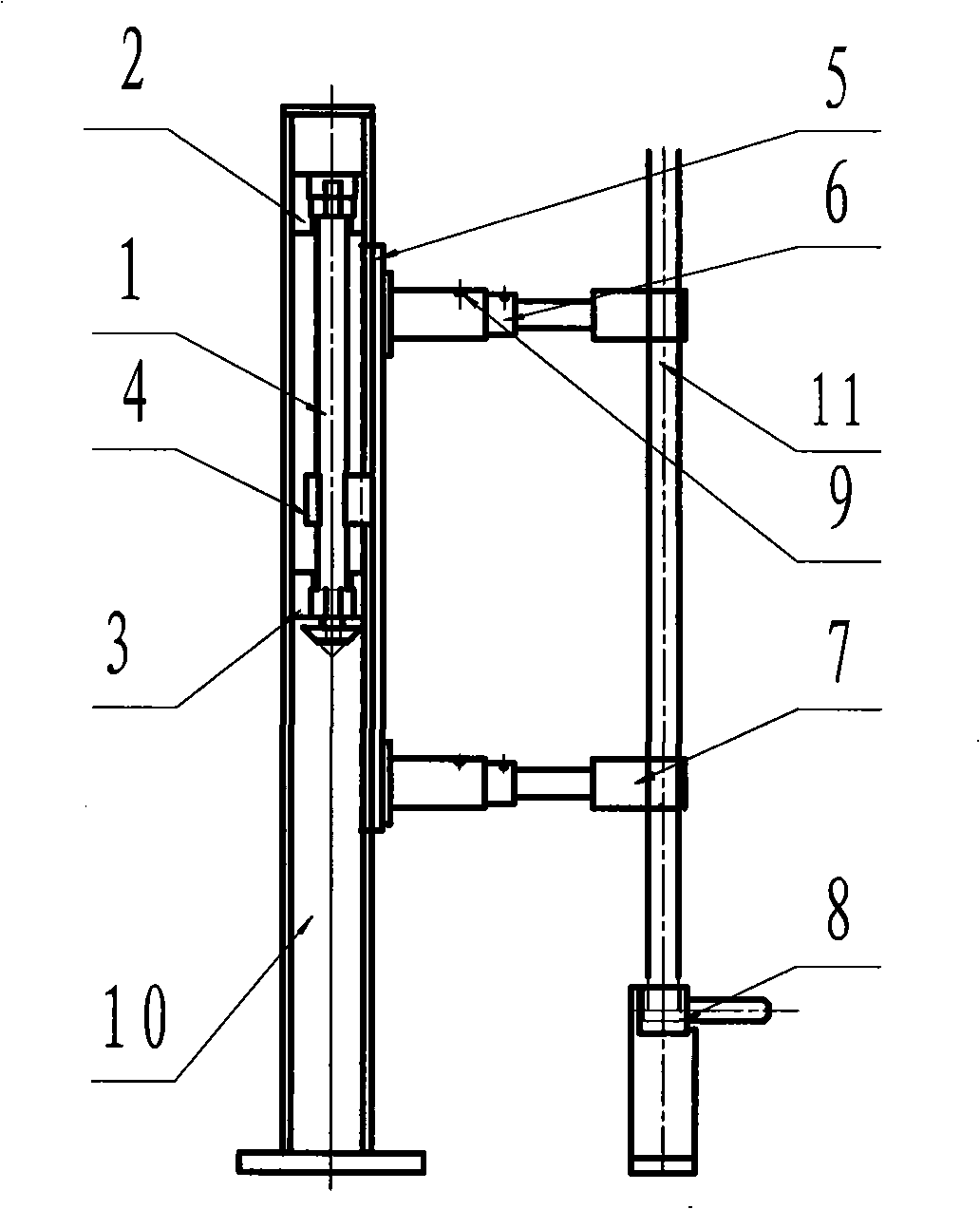

[0034] Between the graphite or graphitized electrodes I, the substrate 8 to be welded is fixed in a horizontal state. For this reason, step down the left / right pedal lever clamping mechanism VI, remove the left / right movable graphite electrode I, and the weld...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com