Universal hydraulic tool for framework machining

A hydraulic and frame technology, applied in metal processing equipment, metal processing machinery parts, positioning devices, etc., can solve problems such as low processing accuracy, inconsistent deformation state, and large human influence factors, so as to improve clamping efficiency and clamping Stable and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

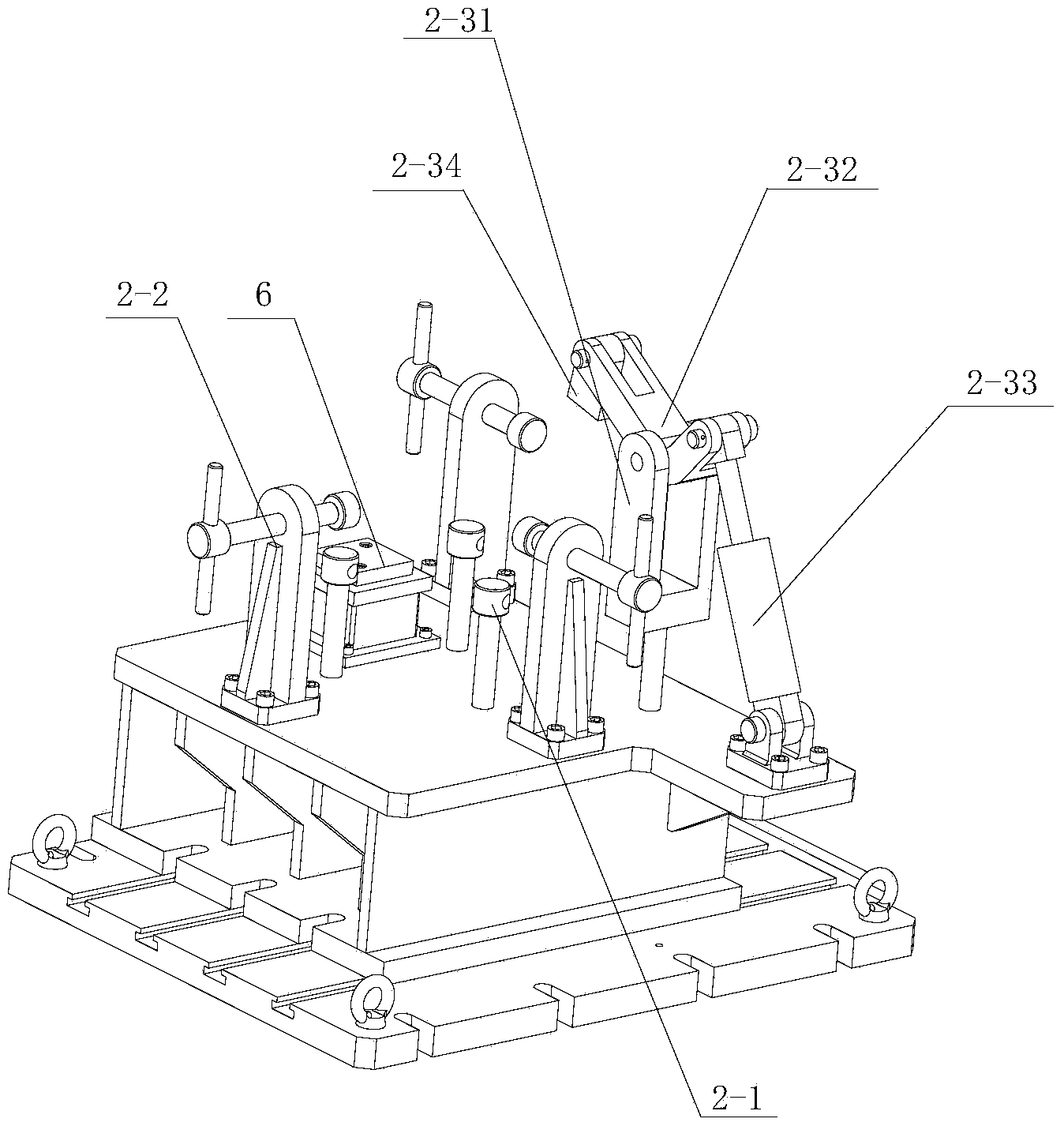

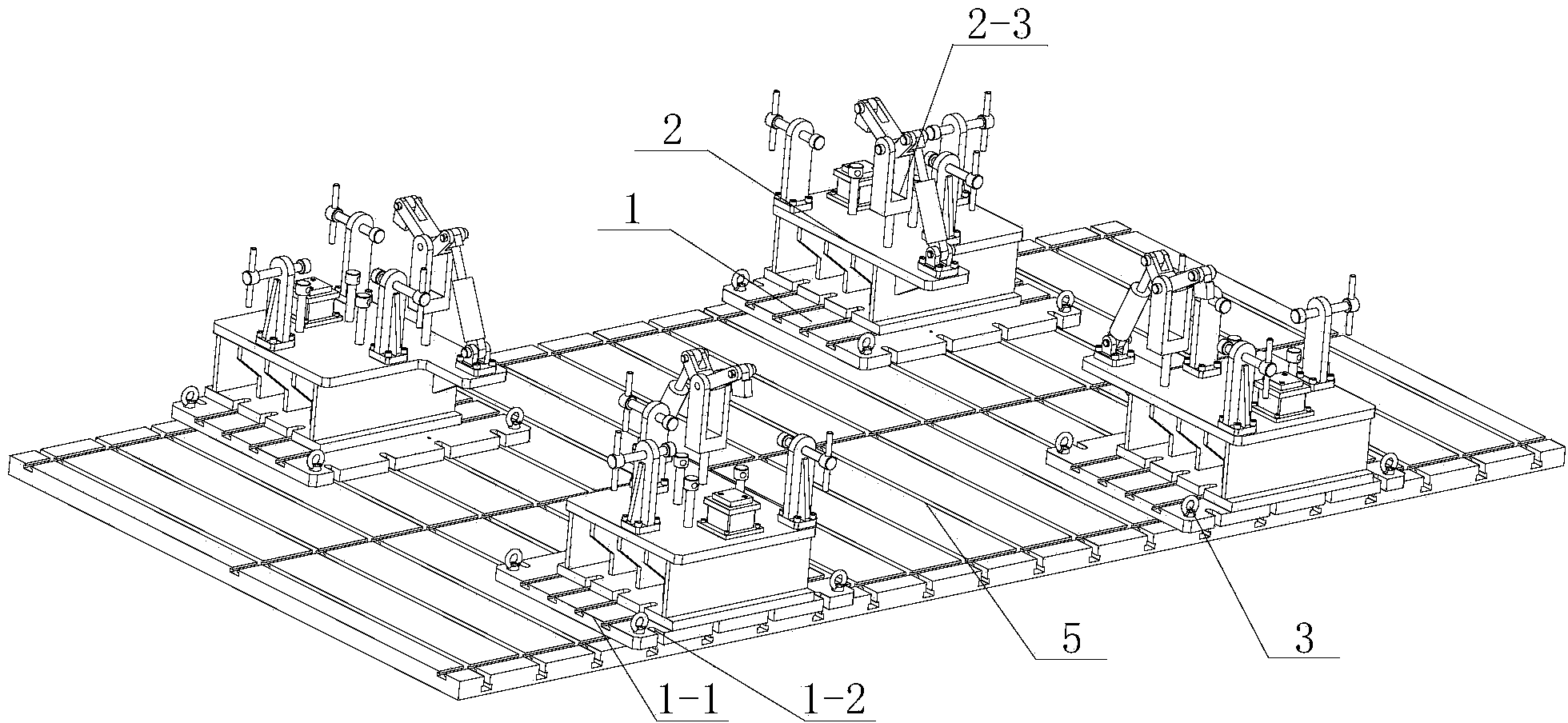

[0014] A general hydraulic tooling for frame processing provided in this embodiment, the structure is as follows figure 1 with figure 2 As shown, it includes a workbench 5, a workbench connection module 1 and four tooling modules 2 installed on the workbench connection module 1. The four corners of the workbench connection module are fixedly installed with hoisting rings 3, and the upper surface of the workbench connection module has Y To the I-shaped groove 1-1, there is a vertical U-shaped groove 1-2 at the X-direction side edges of the workbench connection module. The tooling module includes a positioning device 2-1, an adjusting device 2-2 and Clamping device 2-3, the positioning device is composed of Z-direction positioning surface, Y-direction positioning surface and X-direction positioning surface. The Z-direction positioning surface, Y-direction positioning surface and X-direction positioning surface are all composed of adjusting nuts; The Y-direction adjusting bolt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com