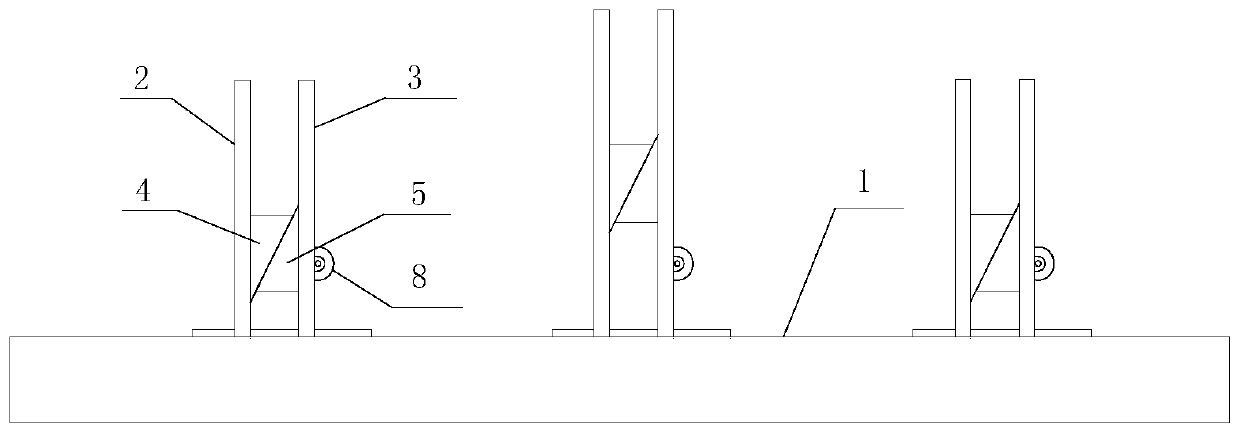

Universal type crankshaft fixture

A general-purpose, crankshaft technology, applied in the field of crankcases, can solve problems such as complex structure, numerous processes, and inability to meet the fixing requirements of crankshafts of different specifications, and achieve a good general effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

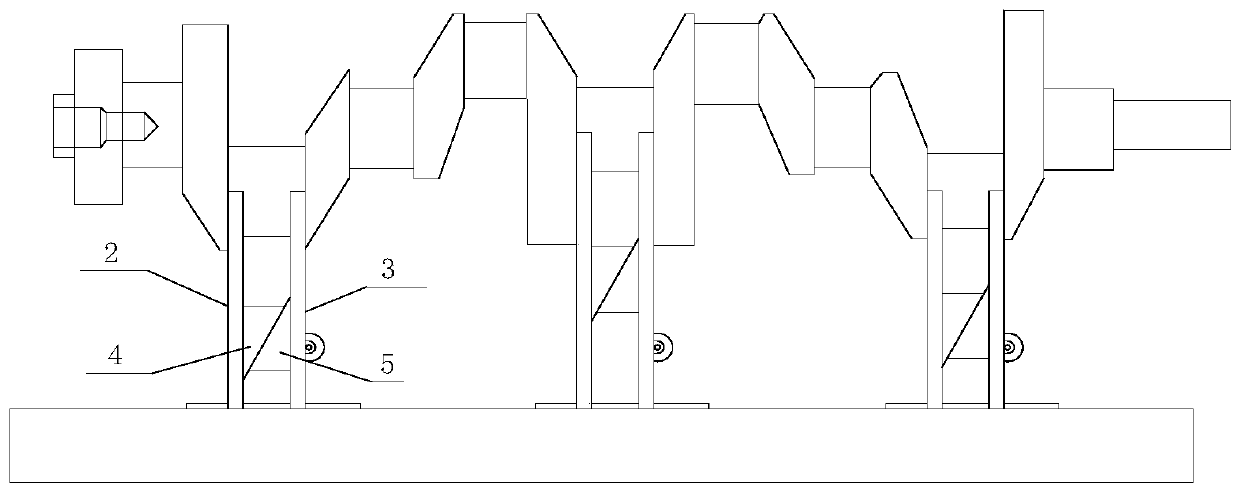

[0030] The opposite plate surface of the second side pressing plate 3 and the first side pressing plate 2 is provided with a vertically extending chute and a rack that can slide up and down in the chute, and the tooth surface of the rack faces away from the first side. One side of the pressing plate 2; the side of the second side pressing plate 3 away from the first side pressing plate 2 is provided with a window communicated with the chute and a gear 8 that is rotatably installed at the window; the gear 8 meshes with the rack, and the second inclined block 5 Fixed with the rack. When the gear 8 rotates, the second inclined block 5 can be promoted to move up and down. And in order to facilitate the rotation of the gear 8, a crank handle is provided on the gear 8 in the present embodiment.

Embodiment 2

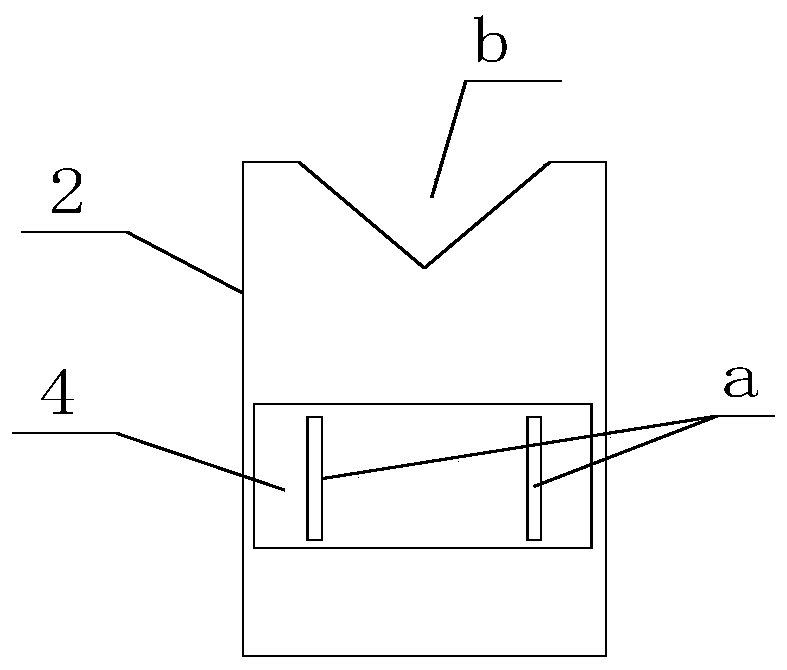

[0032] refer to Figure 4 , the second side pressure plate 3 is provided with a vertically extending chute and a slide block that is located in the chute and slides with the chute on the opposite plate surface of the first side pressure plate 2; the second side pressure plate 3 is far away from the first side pressure plate One side of 2 is fixed with the slider. The second slanting block 5 is provided with a connecting portion 6 fixed thereto, and the connecting portion 6 is provided with a fastening bolt 7 threadedly engaged with it, and one end of the fastening bolt 7 abuts against the second side pressure plate 3 . To lock the second oblique block 5. In this embodiment, the connecting portion 6 is opposite to the side of the second side pressure plate 3 to facilitate the screwing in and out of the fastening bolt 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com