Clamping device for lining rigidity test

A clamping device and bushing technology, applied in the direction of measuring device, workpiece clamping device, elasticity test, etc., can solve the problems of increasing tooling manufacturing cost and management cost, reduce development cost, meet clamping needs, and achieve universal good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

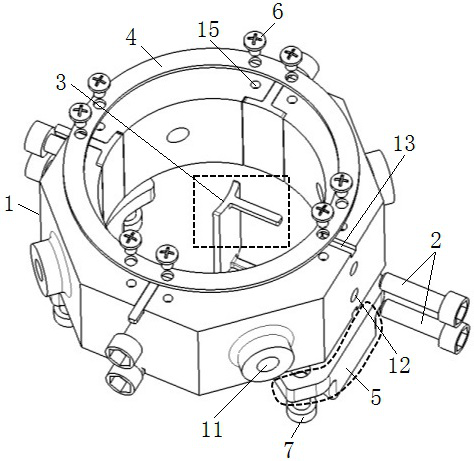

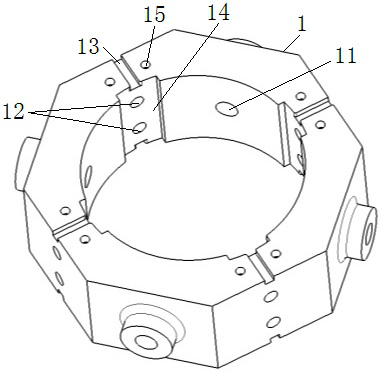

[0020] The present invention will be described in detail below with reference to the accompanying drawings.

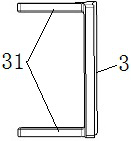

[0021] see Figure 1 to Figure 7 , the shown clamping device for bushing stiffness test includes a cylindrical body 1 in the shape of a regular octagonal prism, and the cylindrical wall of the cylindrical body 1 is provided with a first radial screw hole 11 connected to the test bench and a number of circumferentially uniform Distributed second radial screw holes 12, the first radial screw holes 11 and the second radial screw holes 12 are alternately arranged on adjacent sides of the regular octagonal prism.

[0022] A radial adjustment bolt 2 is screwed into each second radial screw hole 12 , and the end of the radial adjustment bolt 2 extending into the inner hole of the cylinder body 1 abuts against the outer surface of the locking block 3 . The inner side of the locking block 3 is adapted to the outer wall of the bushing 8 to be tested. Clamping requirements for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com