Shifting fork drilling fixture

A drilling fixture and fork claw technology, applied in the field of shifting fork drilling fixtures, can solve the problems of unstable clamping method, low processing efficiency, deformation, etc., and achieve the effects of good clamping effect, reasonable design and easy use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

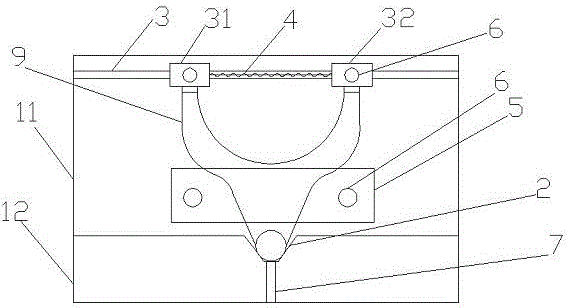

[0017] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

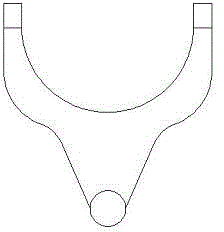

[0018] Such as figure 2 and 3 Said, a fork drilling jig of the present invention includes a chassis, the chassis includes a first bottom 11 and a second bottom 12, the thickness of the second bottom 12 is greater than the thickness 11 of the first bottom, the second The bottom 12 has a trapezoidal groove 2, and the first bottom 11 has a groove 3, and the groove 3 is equipped with a first positioning block 31 and a second positioning block 32 that can move freely in the groove 3, The first positioning block 31 and the second positioning block 32 are connected by a spring 4, the initial length of the spring 4 is less than the distance between the two claws of the shift fork 9, and the first bottom 11 is provided with a threaded hole. The pressure plate 5 is fixed on the first bottom 11 by screwing the bolt 6 into the threaded hole.

[0019] A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com