Method and device for automatically clamping workpieces

An automatic clamping and workpiece technology, applied in the mechanical field, can solve the problems of easy loosening of the workpiece, insufficient clamping force, inconvenient operation, etc., and achieve the effect of strong adaptability and high clamping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Take the method of automatic clamping of Φ8 workpiece as an example, including the following steps:

[0026] (1) Select a suitable spring collet for the workpiece of Φ8, place the spring collet in the lock nut, install the lock nut on the spindle, and adjust the phase of the nut so that it can match the fixing hole. The fixing hole is a non-circular hole, and the shape and size of the inner hole of the fixing hole are consistent with the outer shape and size of the lock nut;

[0027] (2) In the control system, input the linear motion speed of the lock nut as 30cm / s, the rotation speed of the spindle as 2000RPM, the clamping time as 20s, and the clamping torque of the lock nut as 5N.m;

[0028] (3) Start the control system, the servo motor A starts to drive the lock nut to enter the fixing hole at a speed of 30cm / s, so that it cooperates with the fixing hole, and the servo motor A stops when it is in place (at this time, the system automatically records The starting pos...

Embodiment 2

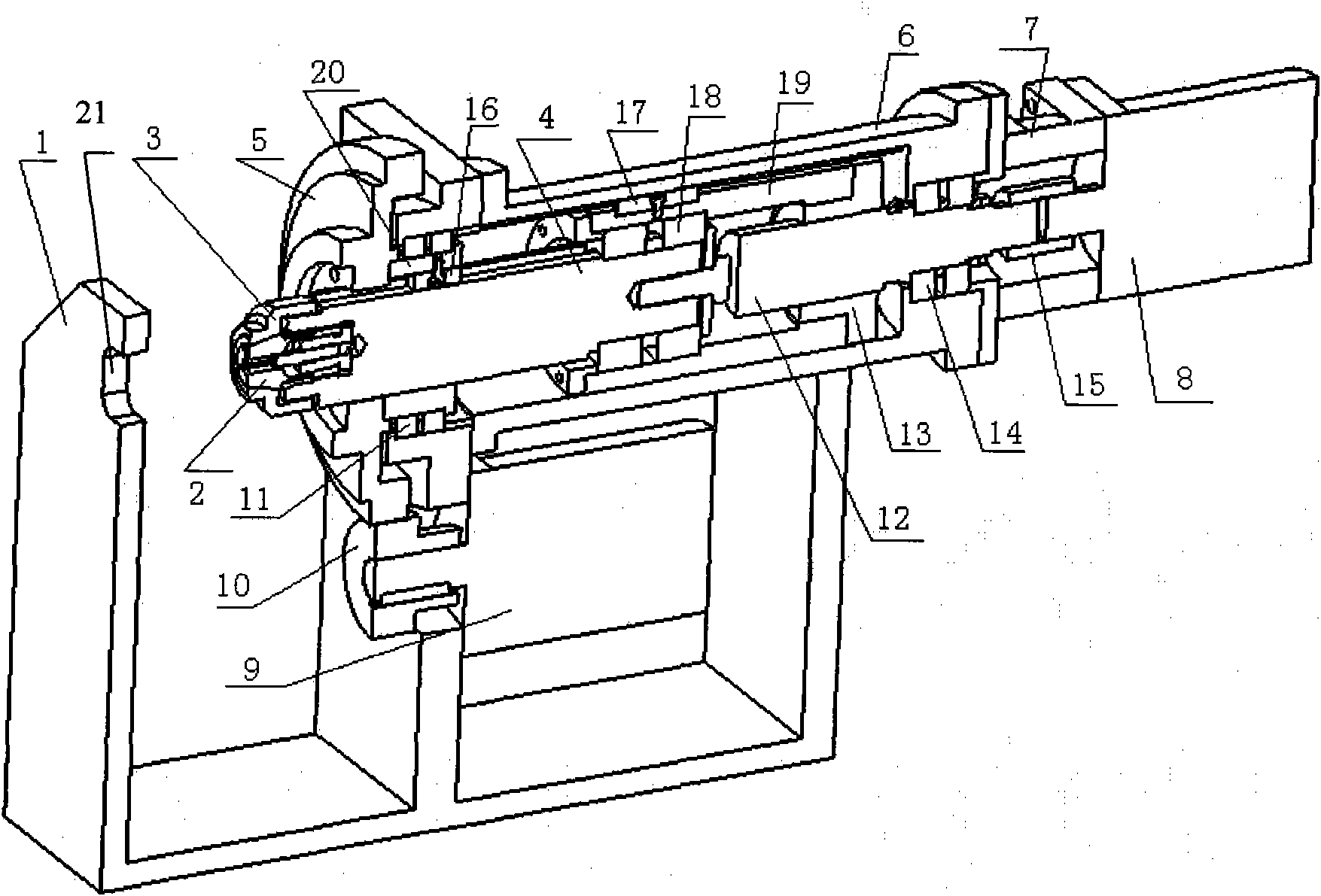

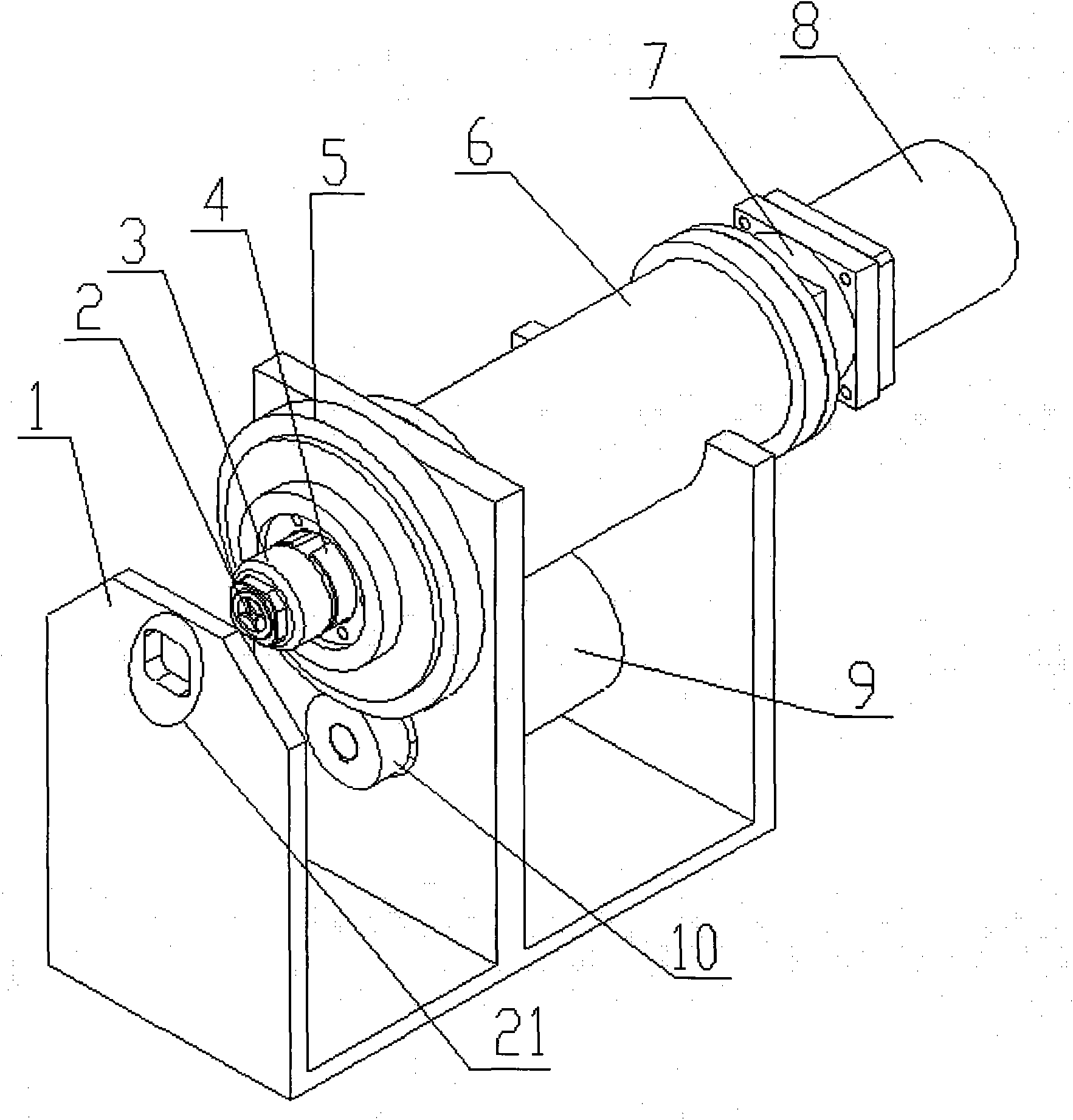

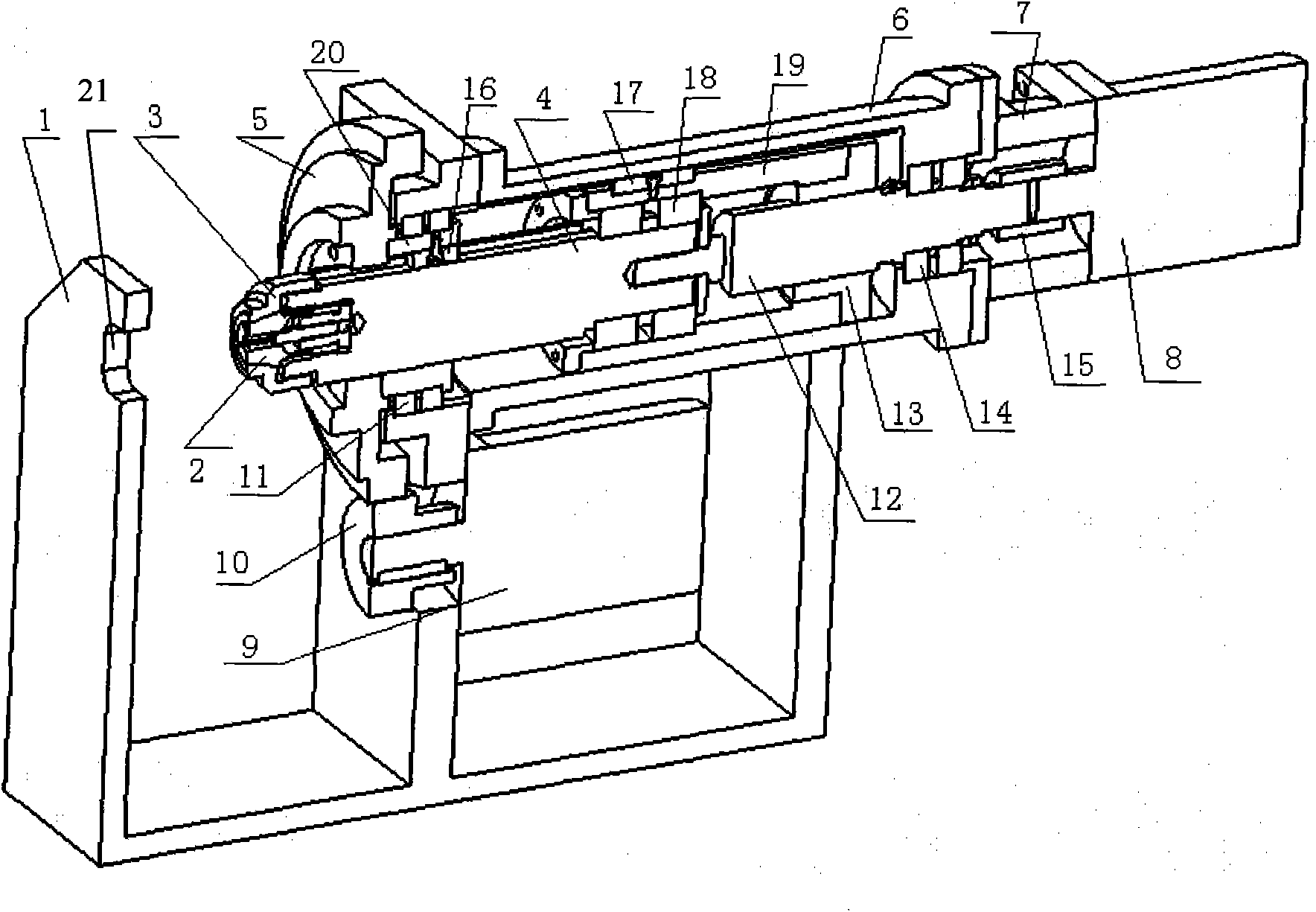

[0032] Such as Figure 1-2 As shown, the workpiece automatic clamping device includes the main shaft moving part, the main shaft rotating part, the frame 1, the sleeve A6 installed on the frame 1, the sleeve B7 connected with the sleeve A6, and the fixing hole 21 is opened on the machine. Rack 1, where:

[0033] The moving parts of the main shaft are composed of the main shaft 4, the lock nut 3 installed on the main shaft 4, the spring collet 2 which is vacantly sleeved in the lock nut 3, the bearing part A sleeved on the main shaft 4, and the The bearing part B, the lead screw nut part, and the servo motor A8 installed on the sleeve B7 are composed. The bearing component A is composed of a bearing seat 20 sleeved on the main shaft 4 , a key 16 fixed on the bearing seat 20 , and a bearing A11 installed on the bearing seat 20 . The bearing part B is composed of a bearing C18 installed on the main shaft 4, a bearing end cover fixed on the main shaft 4, a sliding sleeve 19 matc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com