Flexible fixture device and operation method thereof

A flexible fixture and fixture technology, applied in workpiece clamping devices, positioning devices, clamping and other directions, can solve problems such as affecting the repairability and repair efficiency of blades, inability to achieve precise clamping of blades, and difficulty in precise clamping and positioning. To achieve the effect of simple structure, ingenious design and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

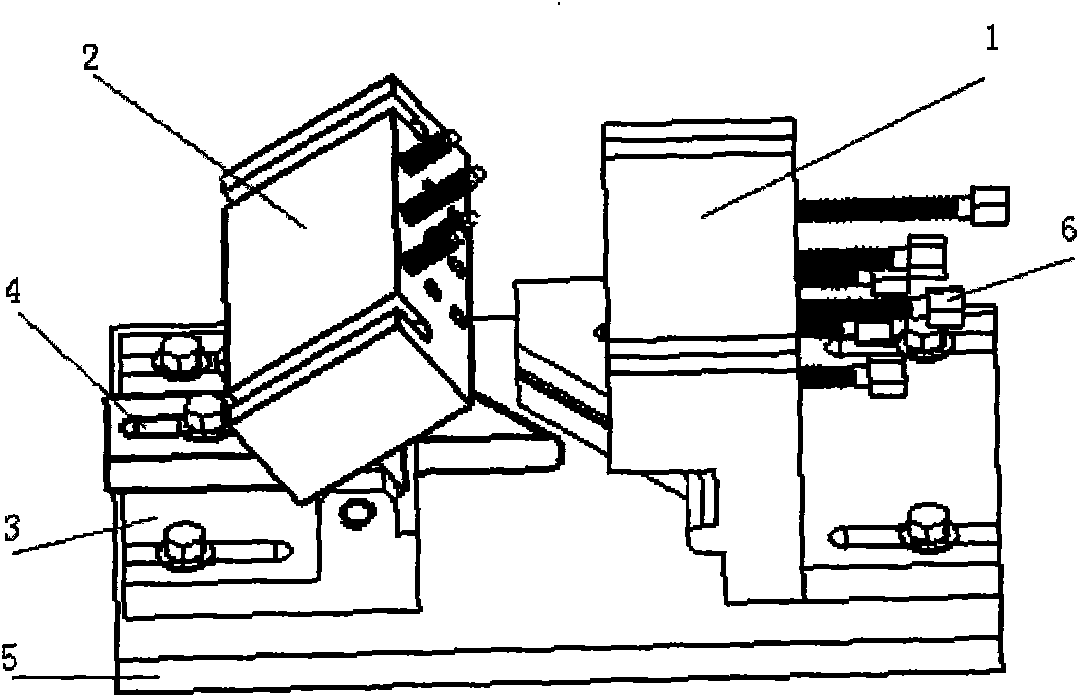

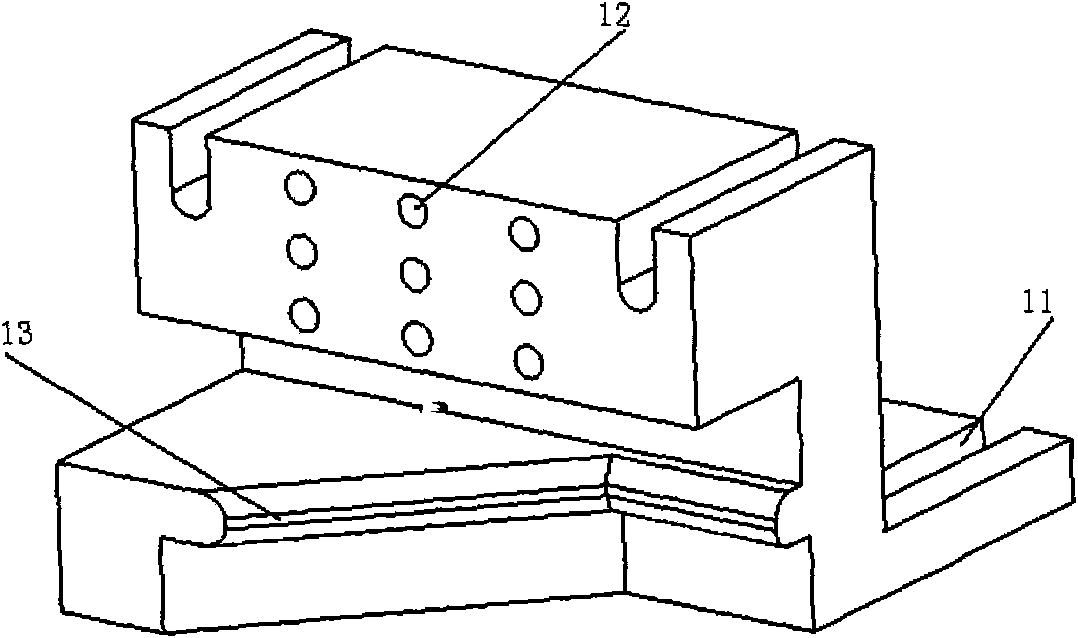

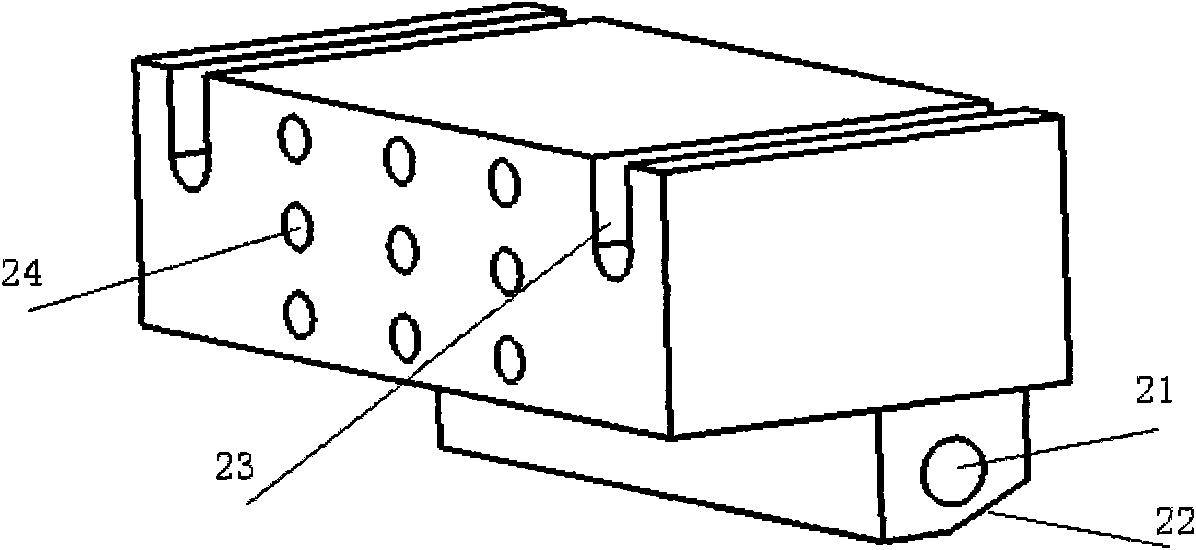

[0037] The structural representation of the flexible clamp device of the present invention is as follows: figure 1 , 2 , 3, 4, and 5, including root pretension block 1, adjustable fixture block 2, adjustable fixture support 3, clamping block 4, base 5, and clamping fixture 6, wherein root pretension block 1 and The adjustable clamp support 3 is respectively fixed on both sides of the base 5 through the position adjustment mechanism 11, 31 provided thereon, and the clamping block 4 is fixed on the adjustable clamp support 3 through the position adjustment mechanism 41 provided thereon. The adjustable jig block 2 is hinged on the adjustable jig support 3, and the root pretension block 1 and / or the adjustable jig block 2 are respectively provided with through holes 12 and 24 through the front and back, and the through holes 12 are provided with holes for processing the surface of the processed parts. Flexible clamping, to ensure that the processed parts can obtain effective and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com