Clamping device of manipulator

A clamping device and manipulator technology, applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve the problems of positioning accuracy errors, irregular shapes, and inability to guarantee gripper fixtures, etc., and achieve the effect of simple structure and strong reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

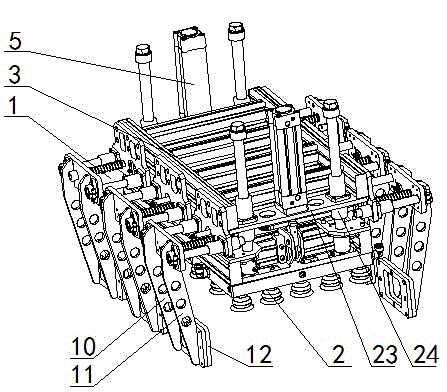

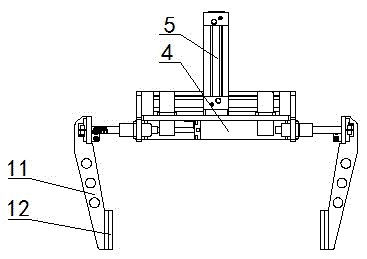

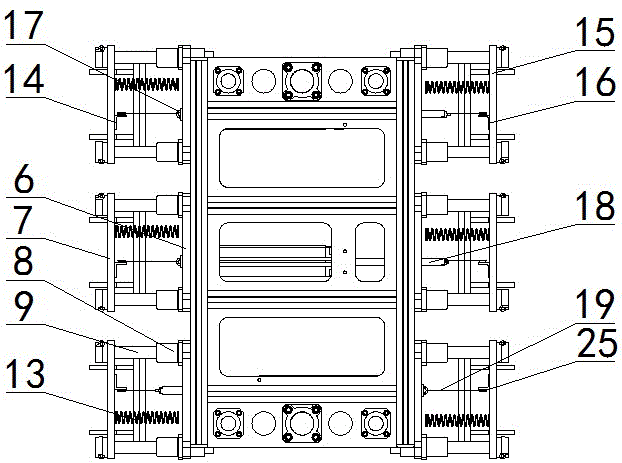

[0016] Embodiment 1: as figure 1 , 2 , 3, a manipulator clamping device, the clamping device includes a floating clamping mechanism 1 and an adsorption mechanism 2, the floating clamping mechanism 1 includes a frame 3, and the frame 3 is located at the adsorption mechanism 1. On the upper end surface, clamping groups are arranged in pairs on the frame 3, and a cylinder A4 for driving the clamping group to open and close is arranged on the upper end surface of the frame 3. On the upper end surface of the frame 3 A cylinder B5 that drives the adsorption mechanism to move up and down is arranged vertically.

[0017] In the present invention, the clamping group includes at least three groups of mechanical finger mechanisms A and mechanical finger mechanisms B respectively connected to both sides of the frame 3 and having the same structure. Cylinder A4 is connected.

[0018] To further describe, the mechanical finger mechanism A includes a connecting plate A6 and a connecting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com