Clamp special for cavity-like part bevel drilling

A technology for special fixtures and parts, which is applied in the field of special fixtures for slant drilling of cavity parts, can solve the problems of poor position accuracy of holes to be machined, poor machining quality of workpieces, and easy deformation of workpieces, so as to achieve short processing cycles and high production efficiency. , to meet the effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

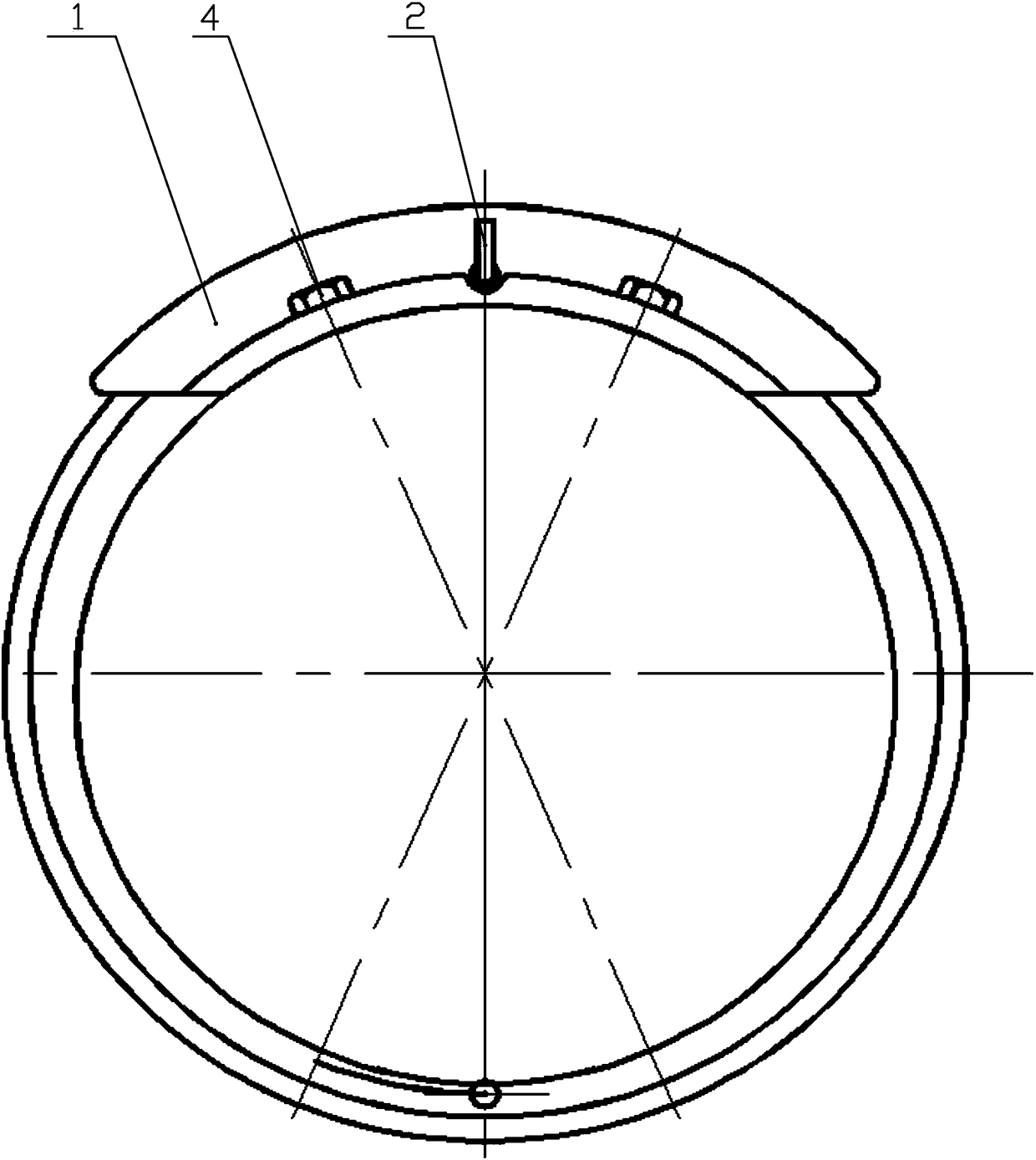

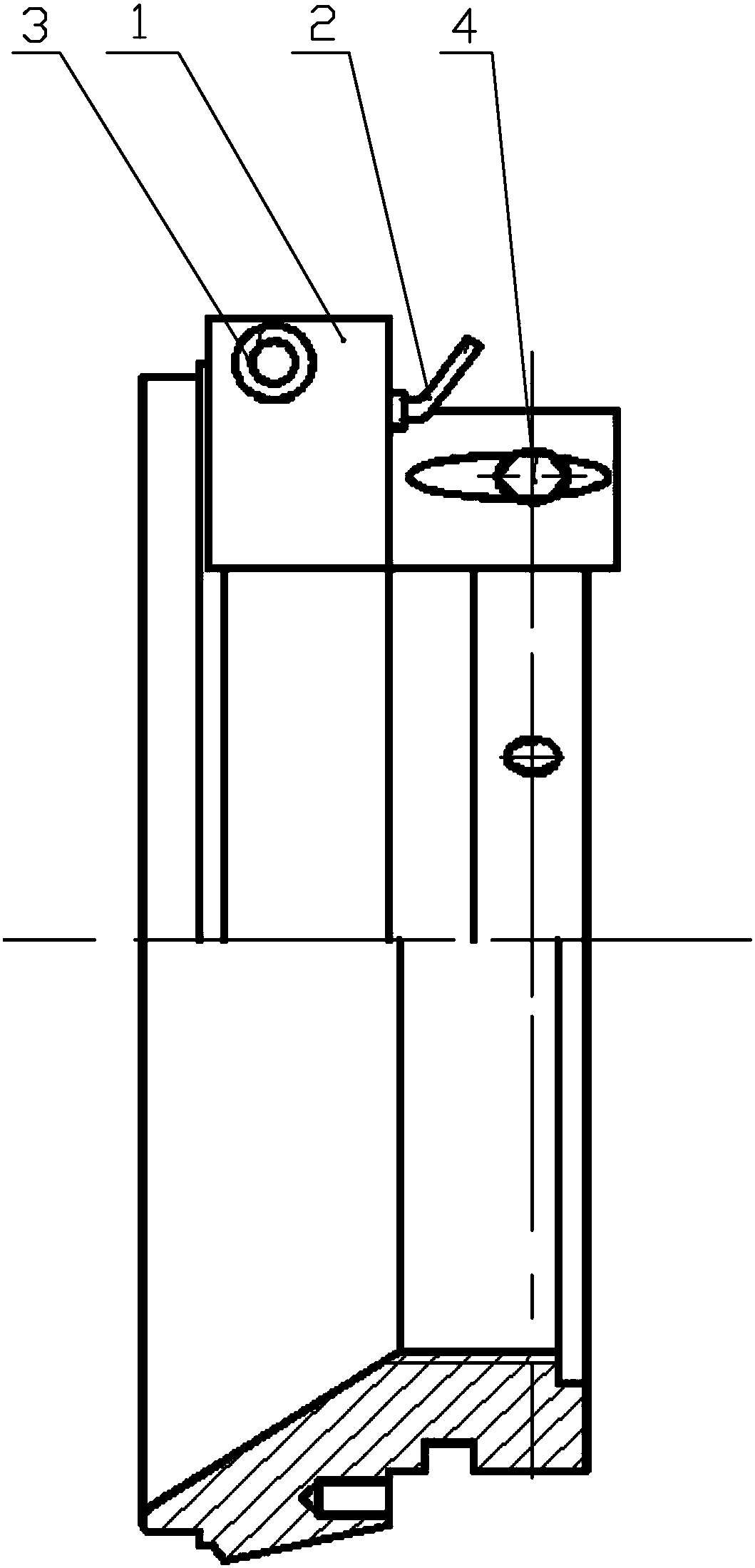

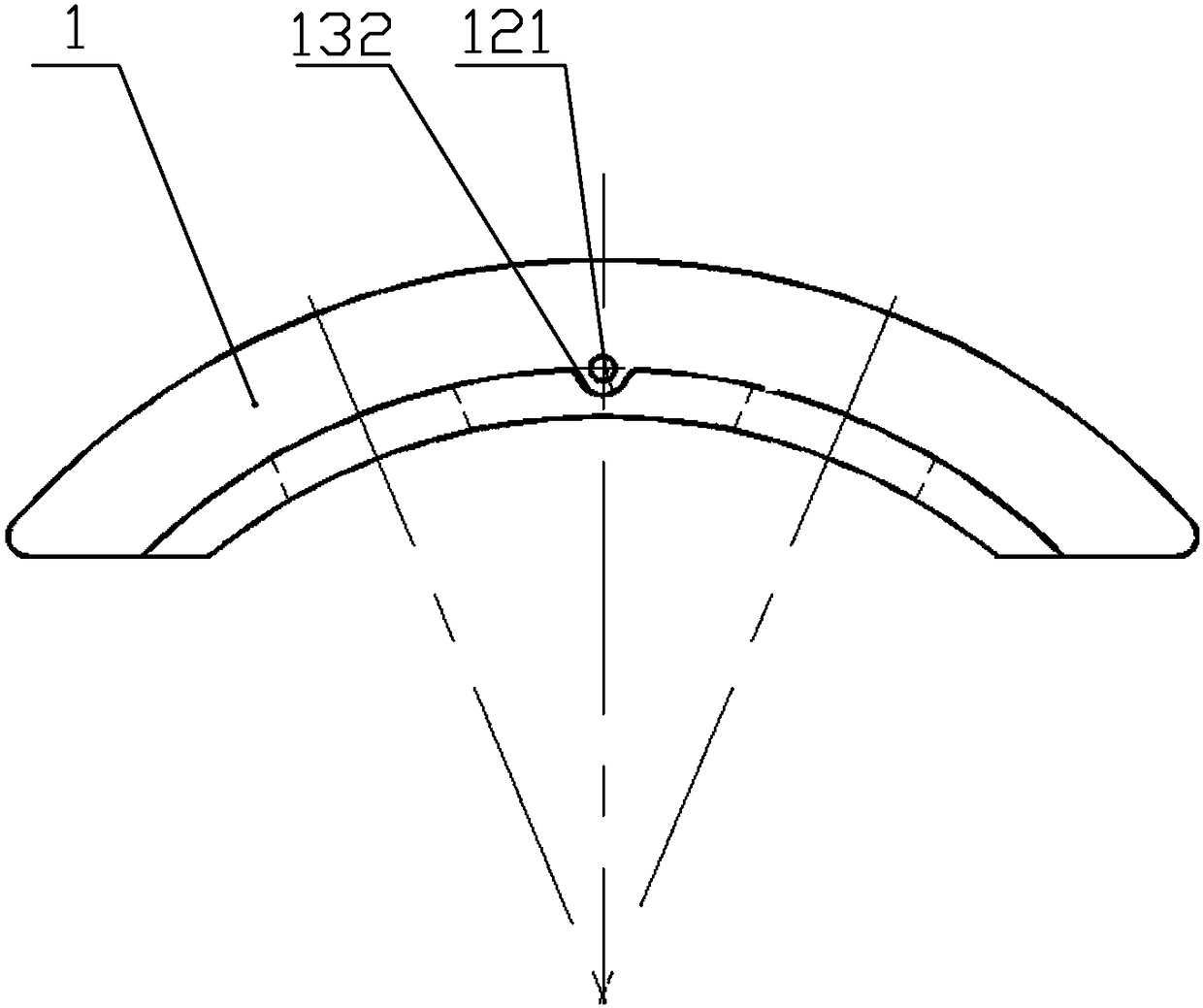

[0028] Specific implementation mode one: combine Figure 1-13 Describe this embodiment, a special fixture for drilling inclined planes of cavity parts, which includes a template body 1, a positioning pin 2, two drill sleeves 3 and two fixing screws 4, and the template body 1 includes from left to The first arc-shaped positioning section 11, the arc-shaped plate 12 and the second arc-shaped positioning section 13, which are coaxially fixed in sequence on the right, the central axis of the drill body 1 coincides with the central axis of the workpiece, wherein the first arc-shaped positioning The inner arc surface of section 11 is in close contact with the outer wall of the circular platform section 101 of the workpiece, the inner arc surface of the second arc positioning section 13 is in close contact with the outer wall of the second cylindrical section 102 of the workpiece, and the left side wall of the arc-shaped plate 12 is in close contact with the workpiece circular platfor...

specific Embodiment approach 2

[0034] Specific implementation mode two: combination figure 2 and Figure 4 To illustrate this embodiment, the positioning hole 131 is an oval long hole. Such a design ensures accurate positioning of the arc-shaped plate 12 and the second arc-shaped positioning segment 13 on the workpiece. Other compositions and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0035] Specific implementation mode three: combination figure 1 , 2 , 7 and 8 illustrate this embodiment, the positioning pin 2 includes a third cylindrical section 21 and a handle 22 obliquely fixed on one end of the third cylindrical section 21, and an annular boss is fixed on the end of the third cylindrical section 21 close to the handle 22 23. During installation, the third cylindrical section 21 is sequentially inserted into the first through hole 121 and the pin hole 104 on the workpiece. Designed in this way, the third cylindrical section 21 plays the role of fixing the arc-shaped plate 12 and the workpiece during installation, and the gap between the third cylindrical section 21 and the pin hole 104, and between the third cylindrical section 21 and the first through hole 121 are uniform. For a tight fit. The annular boss 23 acts as a limiter for the third cylindrical section 21, and the handle 22 facilitates the installation and disassembly of the positioning pin 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com