Clamping structure for fixture

A clamp and clamp plate technology, applied in the field of clamping structures and compact clamping structures for clamps, can solve the problems of the pressing point moving, inapplicable, insufficient space, etc., to avoid clamping deformation, avoid clamps becoming larger, The effect of the compact structure of the fixture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

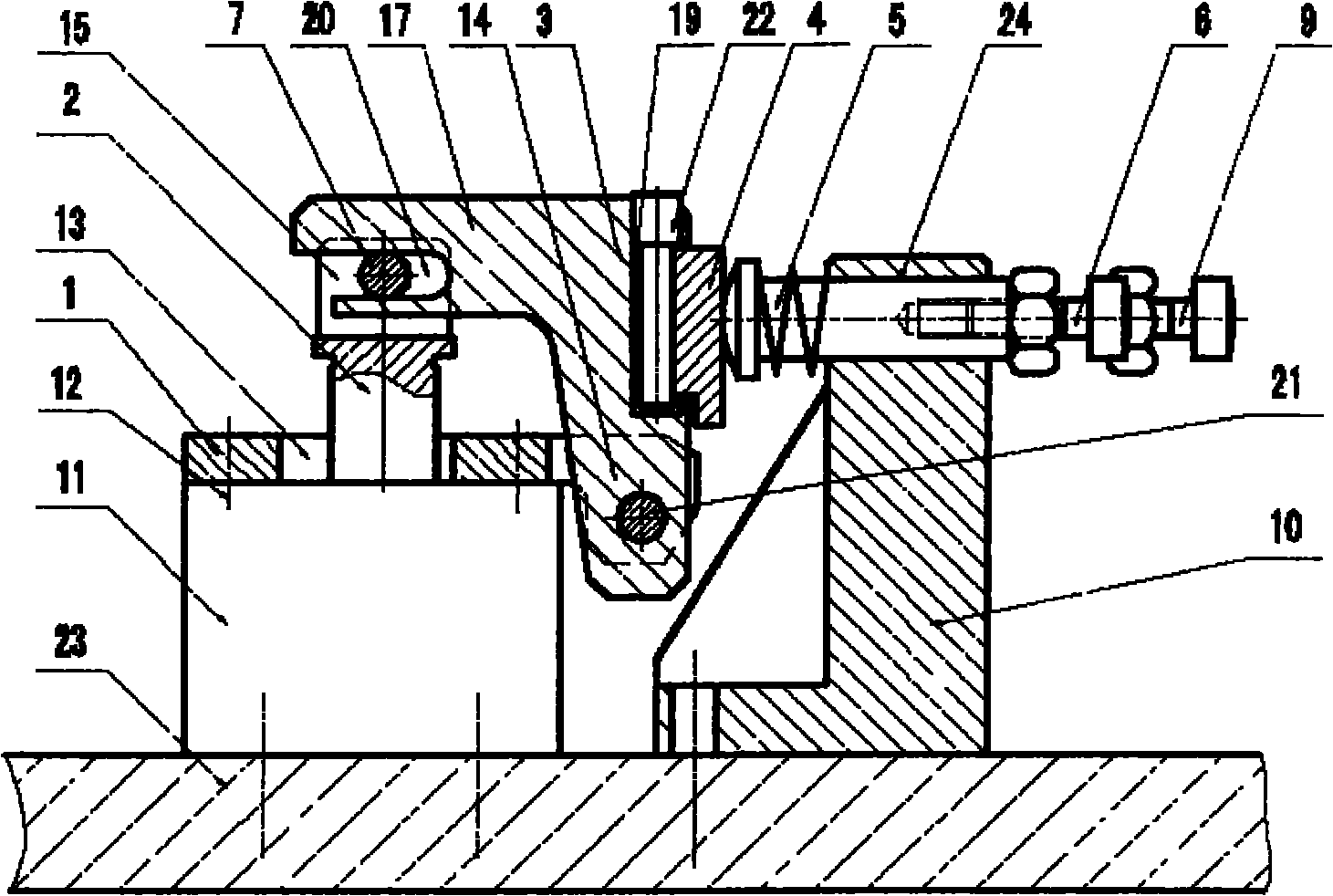

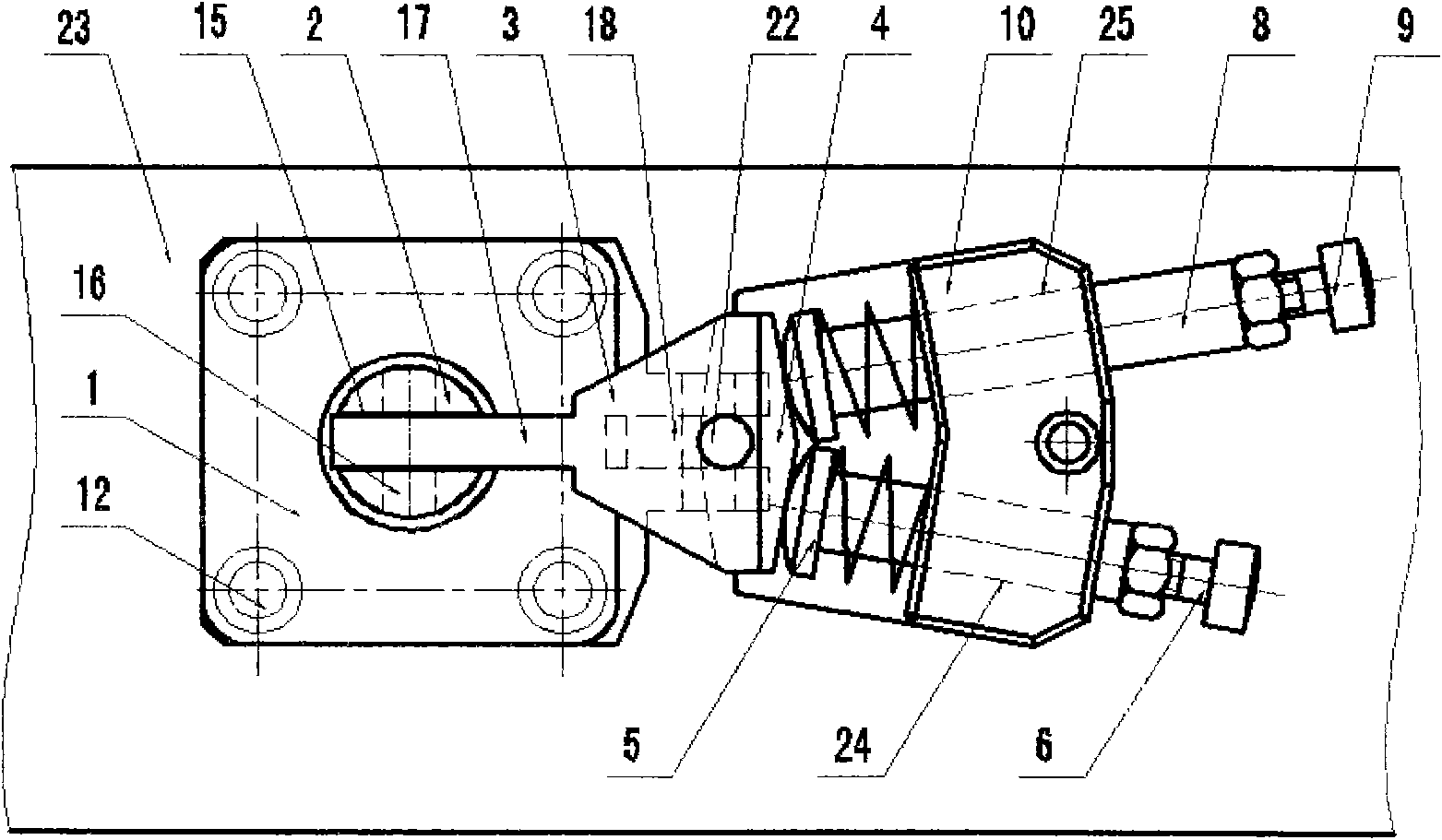

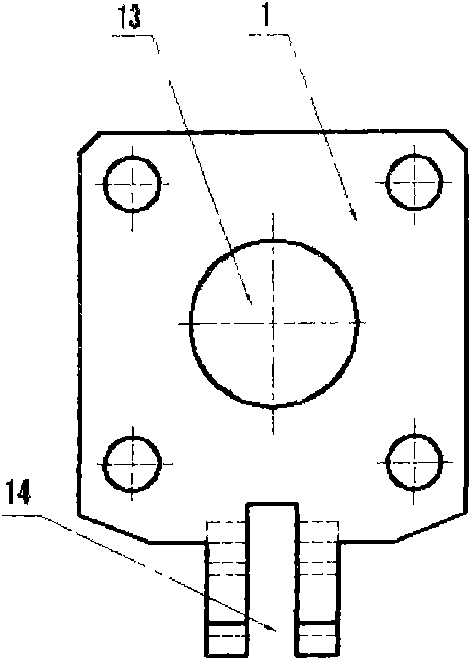

[0017] figure 1 , figure 2 Among them, the present invention mainly includes connecting plate 1, connecting rod 2, crank 3, pressing plate 4, first pressing rod 5, first ejector rod 6, pin 7, second pressing rod 8, second ejector rod 9, base 10 And hydraulic cylinder 11 etc. constitute. The connecting plate 1 is fixed on the hydraulic cylinder 11 by screws 12, a hole 13 is opened in the middle, and a square groove 14 is opened on one side. The lower end of the connecting rod 2 passes through the hole 13 and is fixedly connected with the hydraulic cylinder 11. The upper end of the connecting rod 2 is provided with a square groove 15, and the side is provided with a pin hole 16. One end of the crank 3 is a square block 17, a square boss 18 is arranged at the bottom, and a square groove 19 is arranged on the side of the other end. The size of the square block 17 matches the square groove 15, and the size of the square boss 18 matches the square groove 14. A U-shaped groove 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com