Pneumatic precise clamping device of low-rigidity thin-wall cavity part

A clamping device and cavity-type technology, which is applied in positioning devices, metal processing machinery parts, clamping, etc., can solve the problems of clamping deformation of low-rigidity thin-walled materials, and the inability to realize precise centering of workpieces and turntables. Can not solve problems such as clamping problems well, achieve reliable performance, avoid clamping deformation, and reduce error amplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

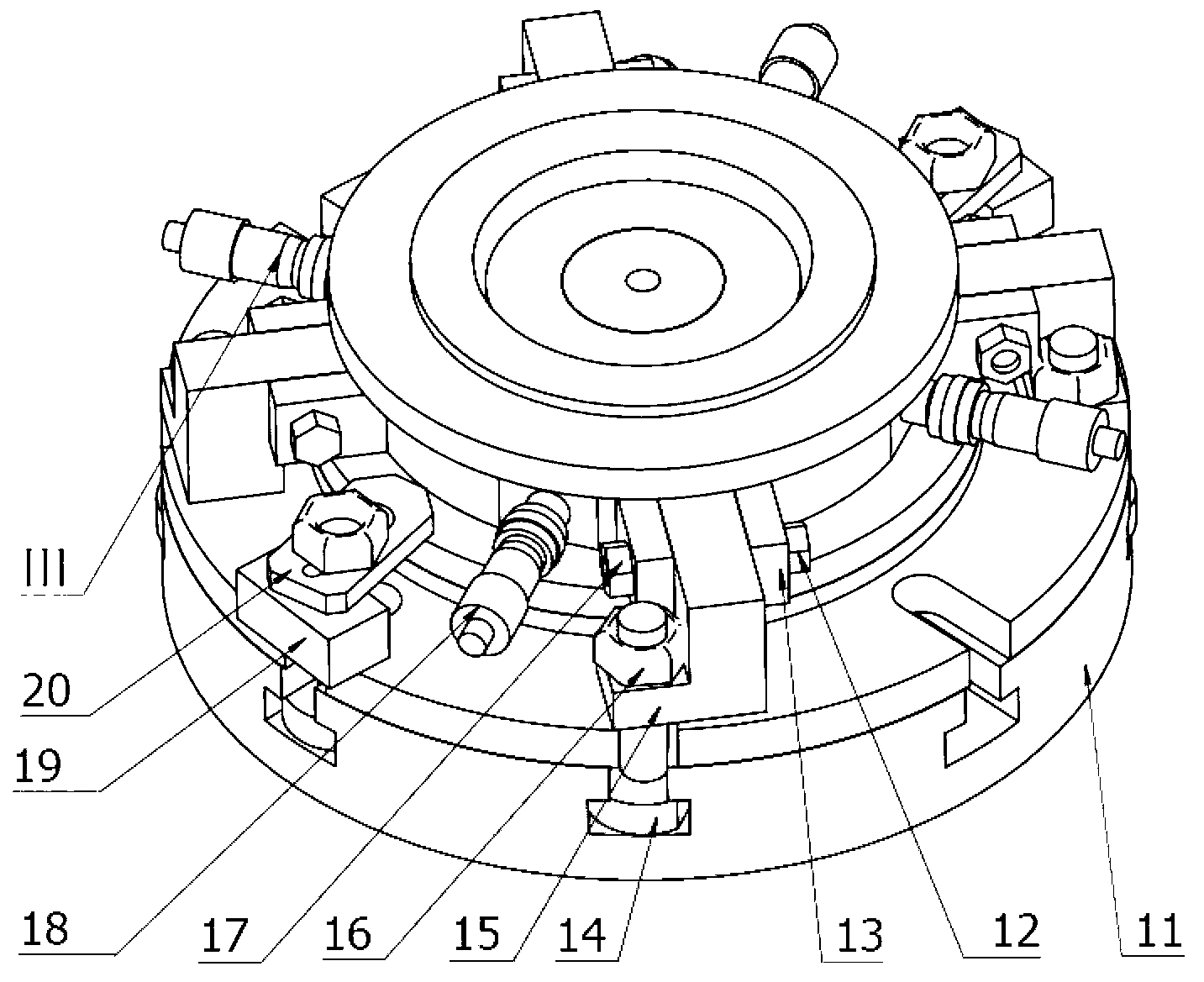

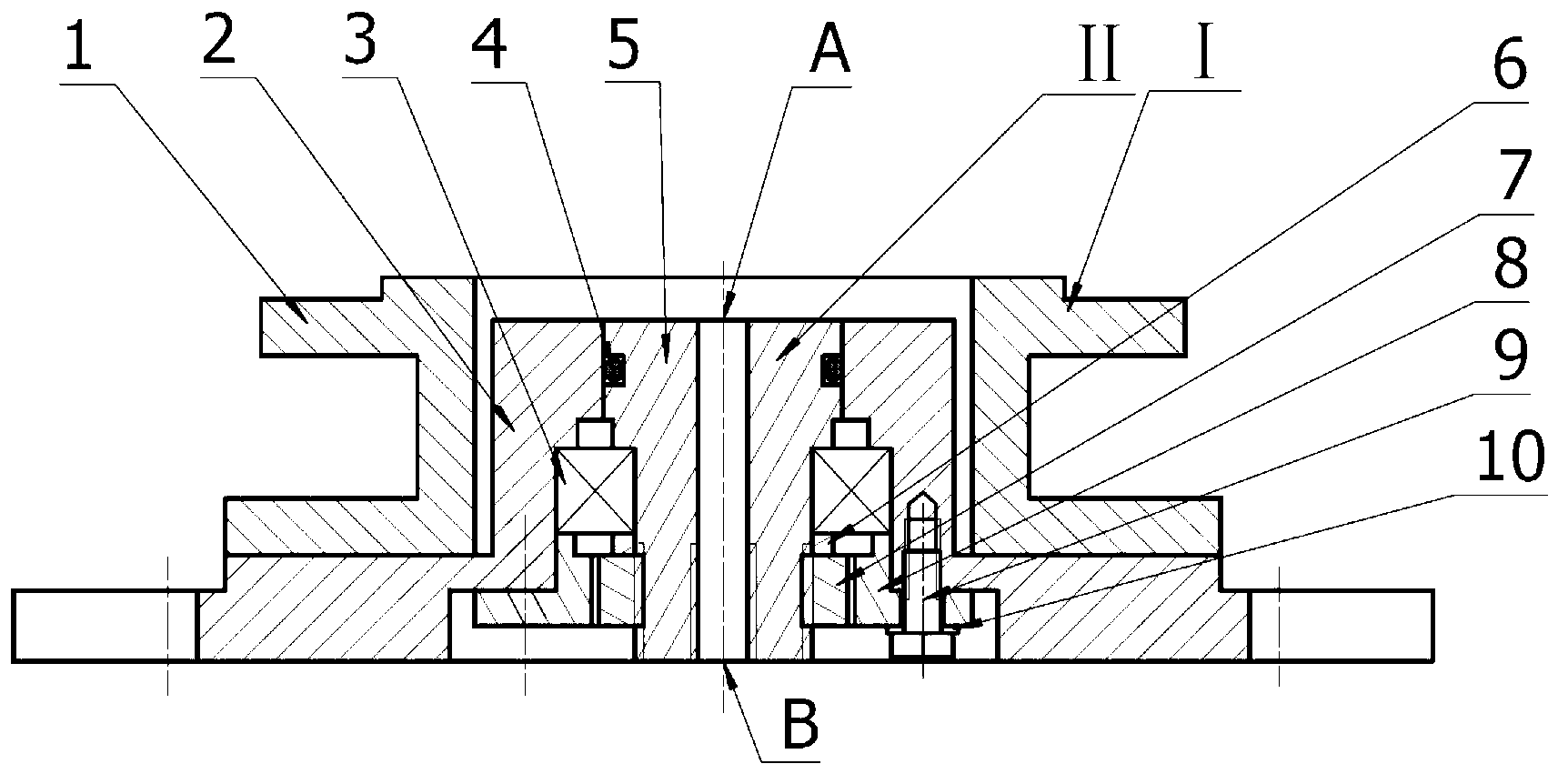

[0011] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and technical solutions. The clamping device is composed of a preliminary positioning part, a pneumatic clamping part and a precision adjustment part. The preliminary positioning part can perform preliminary positioning of the workpiece and limit the degree of freedom of the horizontal direction of the workpiece. The pneumatic clamping part makes the inside of the workpiece cavity form a The vacuum environment absorbs the workpiece on the surface of the fixture, restricts the freedom of the vertical direction of the workpiece, and finally realizes the precise centering of the part by adjusting the precision feed components.

[0012] see figure 1 , figure 2 , The pneumatic clamping device of the present invention is divided into three parts: preliminary positioning part I, pneumatic clamping part II, and precision adjustment part III.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com