Aluminum alloy magazine welding deformation control device and method

A welding deformation and control device technology, applied in the direction of auxiliary devices, welding equipment, welding equipment, etc., can solve the problems of air hole defects, warping deformation, non-fusion and other problems in the welding seam, achieve the elimination of welding residual stress, reduce welding deformation, Effect of preventing clamping deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

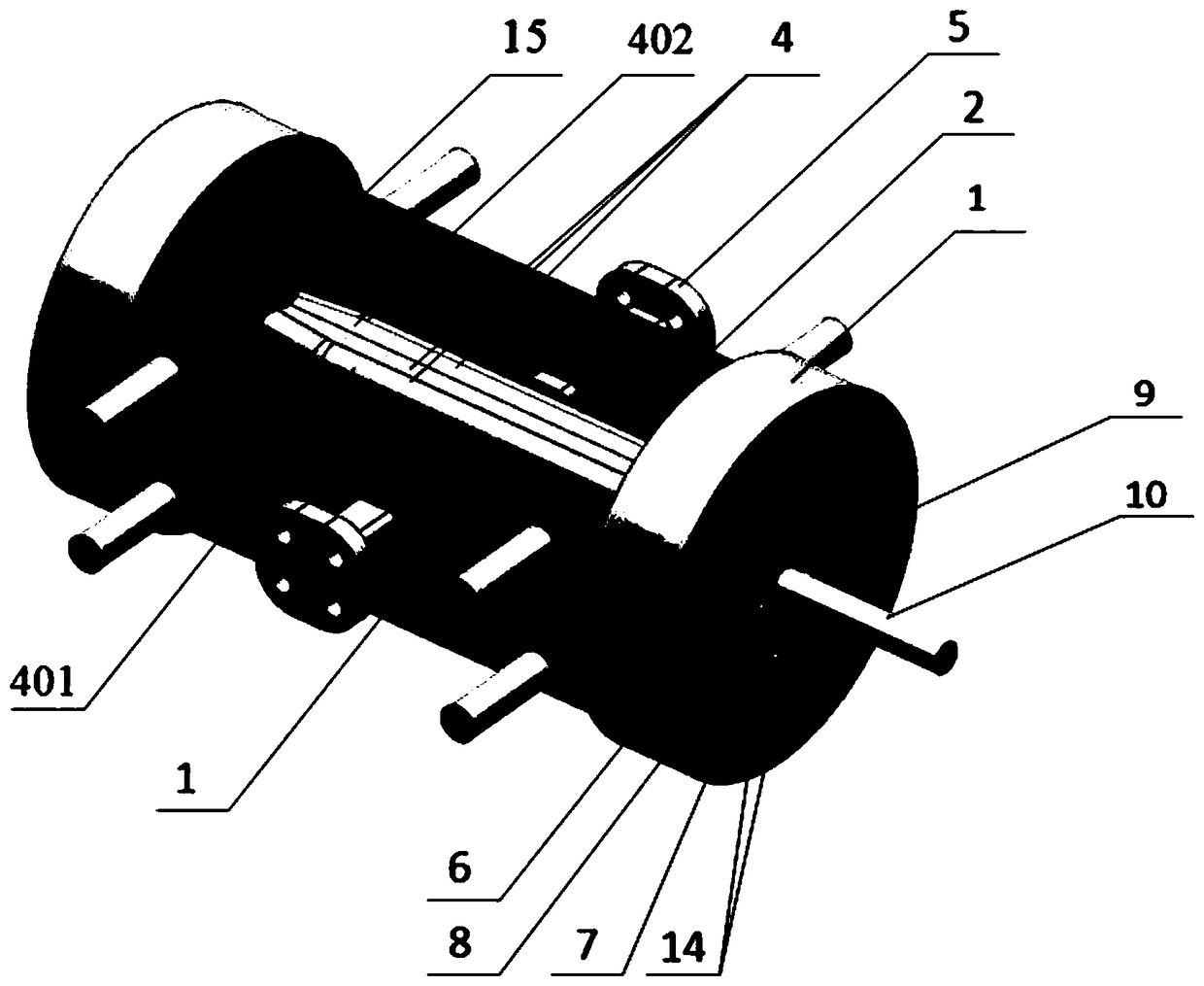

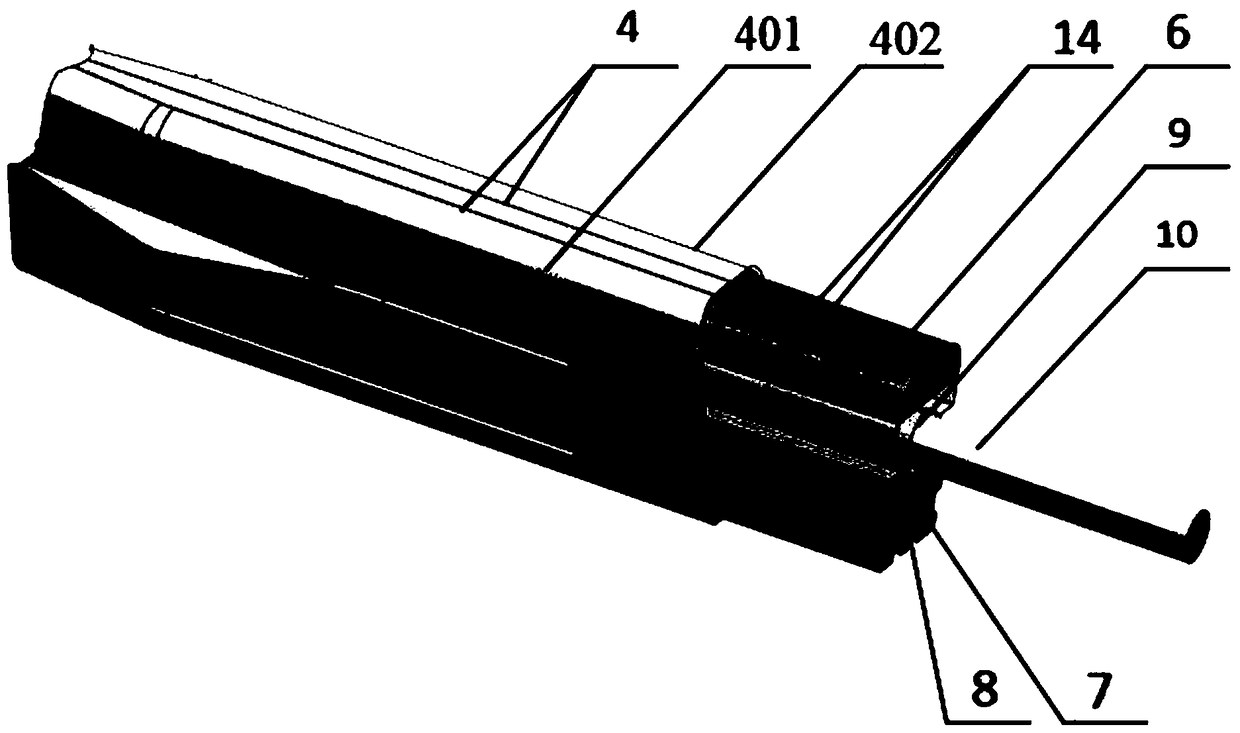

[0036] A kind of aluminum alloy magazine welding deformation control device, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, it includes an outer mold for positioning the outer contour of the magazine 4, a core mold for positioning the inner surface of the magazine 4, and a turning mechanism 1 connected at both ends of the magazine and used for turning over the magazine; wherein , the magazine 4 includes a left half-type 401 and a right half-type 402, the gap between the left half-type 401 and the right half-type 402 constitutes a welding seam, after the magazine 4 is installed on the control device, it is ready to start welding on the magazine 4 When welding the surface, the welding torch 15 is placed as figure 1 the location shown;

[0037] The outer mold includes a vertically arranged left mold 1, a right mold 2 and a horizontally arranged bottom mold. In the middle of the bottom mold, there is a hollow part for showing the weld seam. When the bottom film ...

Embodiment 2

[0047] 2A12 aluminum alloy magazine welding deformation control method, using the aluminum alloy magazine welding deformation control device in Embodiment 1 to carry out welding deformation control, the specific steps include:

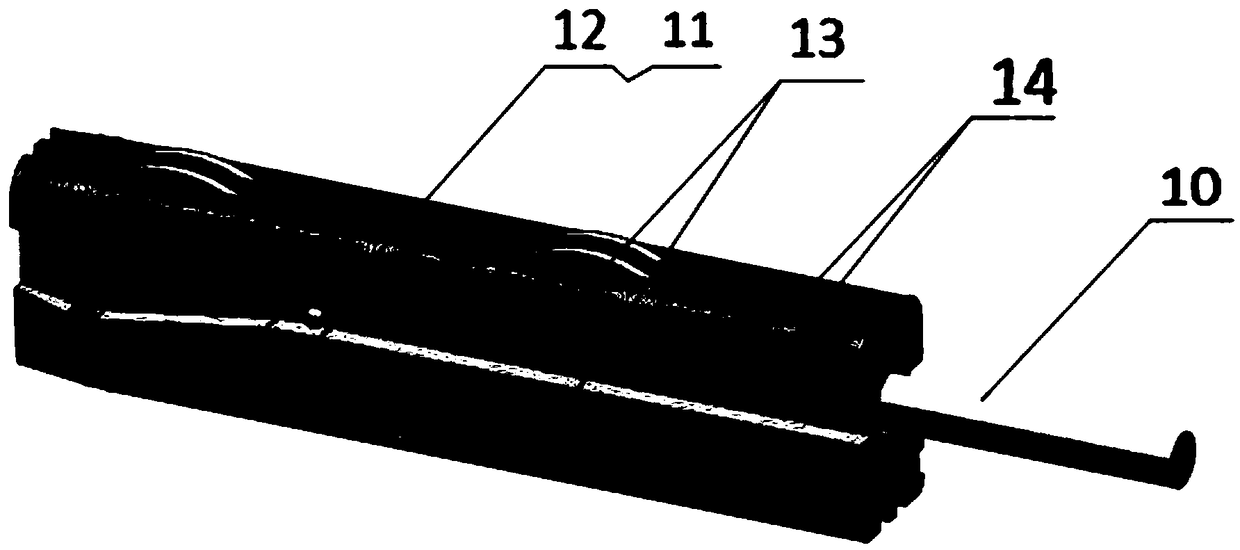

[0048] Step 1: Place the left half and right half of the magazine to be welded in the space enclosed by the left mold, right mold and bottom mold, and push the left and right molds towards each other until the left half of the magazine is formed The distance between the welding seam and the right half is 0.12mm. Insert the upper mandrel into the inner cavity of the magazine and fit it with the inner top wall of the magazine. Insert the lower mandrel into the inner cavity of the magazine and fit it with the magazine Fit the bottom wall of the box, wedge the middle mandrel between the upper follow-up mandrel and the lower follow-up mandrel, push the ejector rod in the middle mandrel, and push out the displacement sensor radially, so that the center mandre...

Embodiment 3

[0057] A welding deformation control device for an aluminum alloy magazine, comprising an outer mold for positioning the outer contour of the magazine, a core mold for positioning the inner surface of the magazine, and a core mold connected to both ends of the magazine and used for flipping the magazine the turning mechanism;

[0058] The outer mold includes a vertically arranged left mold, a right mold and a horizontally arranged bottom mold, a hollow part for showing weld seams is arranged in the middle of the bottom mold, and the space enclosed by the left mold, the right mold and the bottom mold For accommodating magazines, push mechanisms for horizontally pressing magazines are provided in the middle of the left mold and the right mold respectively;

[0059] Described mandrel comprises the upper follow-up mandrel that can be attached to the inner top wall of the magazine and the following follow-up mandrel that can be attached to the inner bottom wall of the magazine. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cross-sectional area | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com